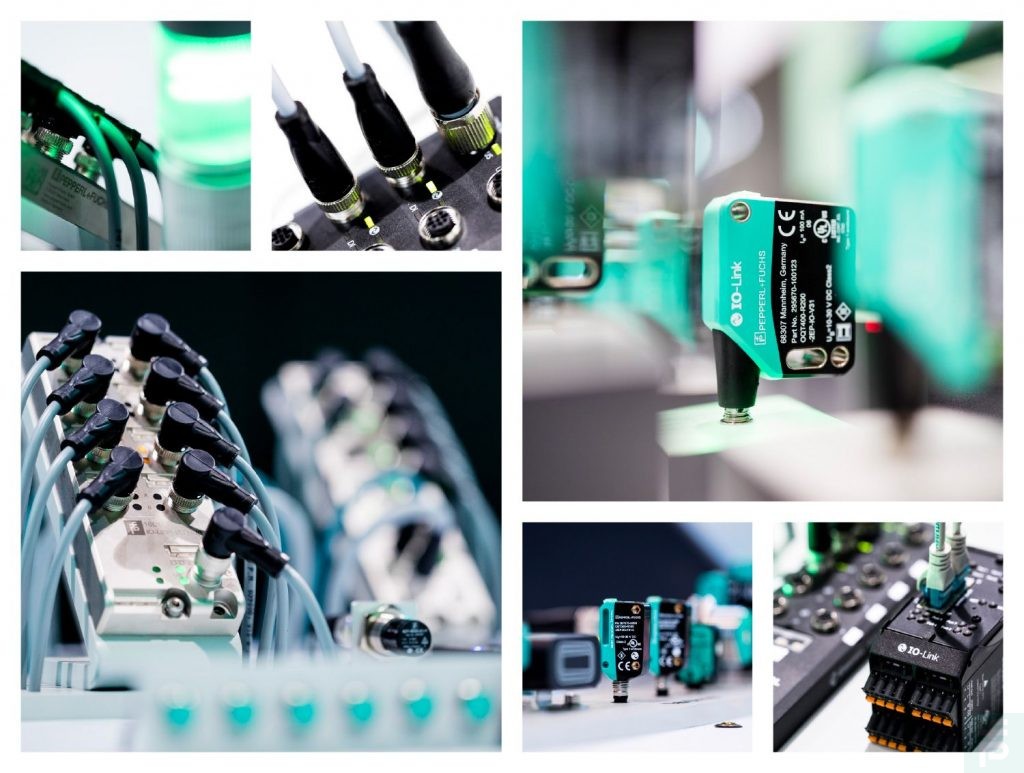

IO-Link

Learn about the advantages and application scenarios of IO-Link devices on the Pepperl+Fuchs blog. IO-Link enables reliable data transmission and transparent communication across all production processes down to the field level and has become an indispensable part of modern automation. Smart IO-Link devices and IO-Link masters from Pepperl+Fuchs, supporting IIoT protocols such as OPC UA, MQTT, and REST API, pave the way to Industry 4.0.

IO-Link

Learn about the advantages and application scenarios of IO-Link devices on the Pepperl+Fuchs blog. IO-Link enables reliable data transmission and transparent communication across all production processes down to the field level and has become an indispensable part of modern automation. Smart IO-Link devices and IO-Link masters from Pepperl+Fuchs, supporting IIoT protocols such as OPC UA, MQTT, and REST API, pave the way to Industry 4.0.

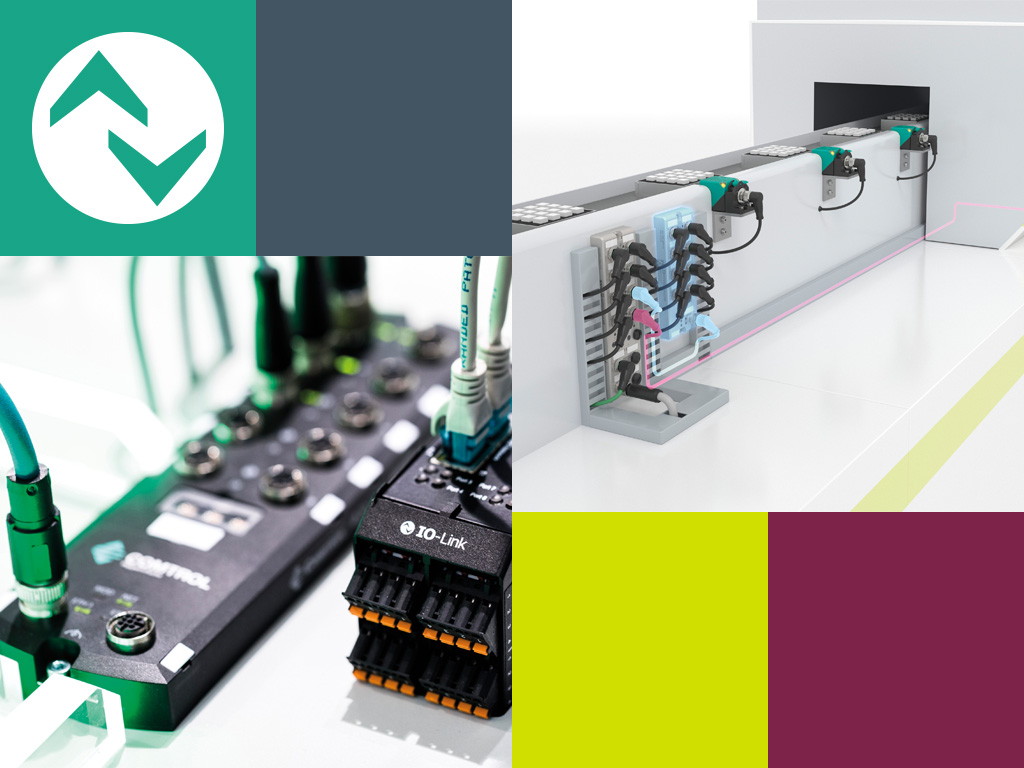

ASi-3, ASi-5, and IO-Link: A Comparison of Three Communication Protocols

As simple and comparatively cost-efficient wiring technologies for sensors and actuators in the field, AS-Interface and IO-Link combine high functionality, flexibility, and reliability. In this blog article, learn where to use ASi-3, ASi-5 and IO-Link, and what makes these communication protocols so special.

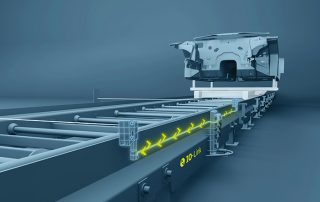

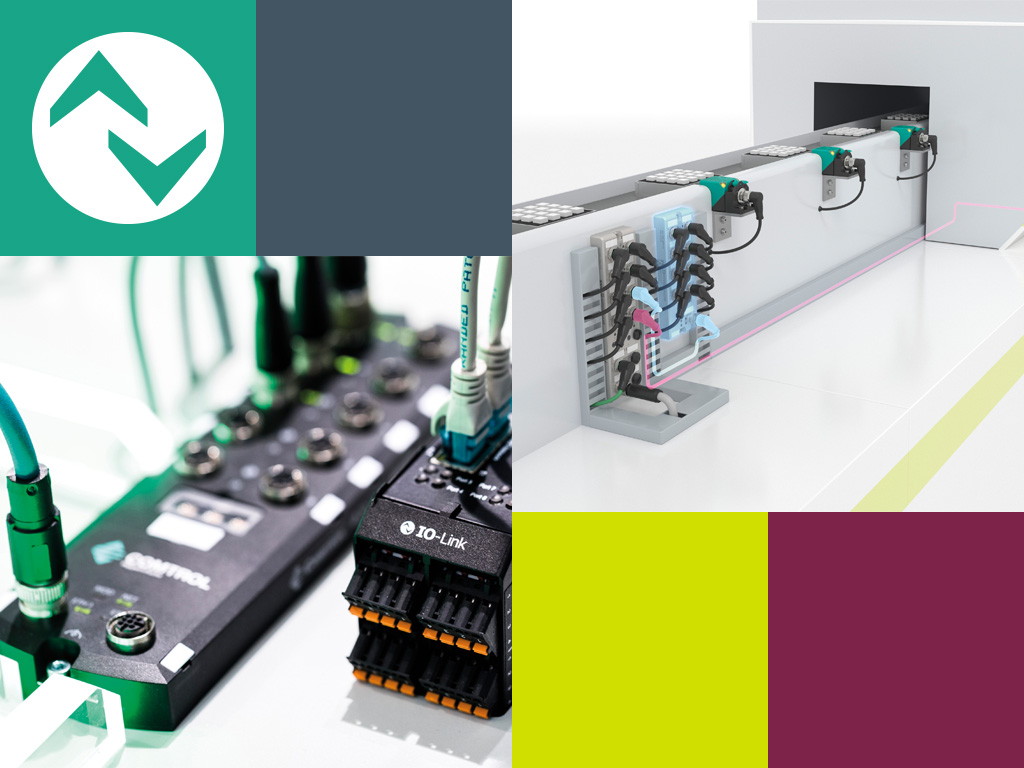

Intelligent Valve Control with IO-Link in Conveyor Technology

Pneumatic valves are widely used in material handling systems. Learn how IO-Link valve connectors from Pepperl+Fuchs can make standard valves smart and add value to your application.

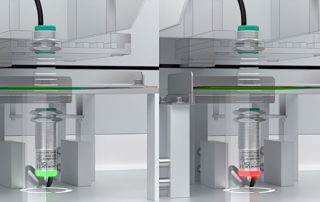

Ultrasonic Double Sheet Sensors with IO-Link Make Material Layer Detection Simple and Reliable

When it comes to reliably detecting sheets of various materials such as paper, plastic, wood, sheet metals, or even highly reflective solar wafers in industrial processes, ultrasonic double sheet sensors offer an ideal solution. This is now easier than ever with two new series of IO-Link double sheet sensors in M18 or M30 design.

IO-Link Device Offline Parameterization Using PACTware

When connected to an IO-Link master, IO-Link devices offer a variety of benefits to the control systems in a plant, such as online configuration and parameterization, simplified device exchange, and even data acquisition via OPC UA and MQTT. For commissioning and test reasons, however, you may wish to configure and parameterize an IO-Link device outside the plant. This blog article supports you in offline parameterization of IO-Link devices using PACTware.

Condition Monitoring and Predictive Maintenance with IO-Link Rotary Encoders

With the ENA**TL-**IO-Link, Pepperl+Fuchs was one of the first manufacturers to launch an absolute rotary encoder with IO-Link interface. Learn how you can benefit from easy configuration and integration with this IO-Link rotary encoder, while at the same time monitoring the status of your plants in a cost-effective manner.

How RFID with IO-Link Eases Machine Access

The use of RFID for machine access control and operation is nothing new. Depending on the application, different frequency ranges are used, either LF, HF, or UHF. Recently, there has been a trend that HF read/write heads with IO-Link are increasingly being used for precisely these applications. In this blog article we take a closer look at this topic and show you possible use cases.

IO-Link as a Retrofit Solution for Legacy Systems

In this article, you will learn more about the advantages of intelligent communication technology and how you can modernize existing systems with IO-Link masters from Pepperl+Fuchs.

Industrial Internet of Things with MQTT and IO-Link Technology

Do you wonder if switching to MQTT-compliant devices could improve your application? Here is what you must know to build an IIoT-ready system.

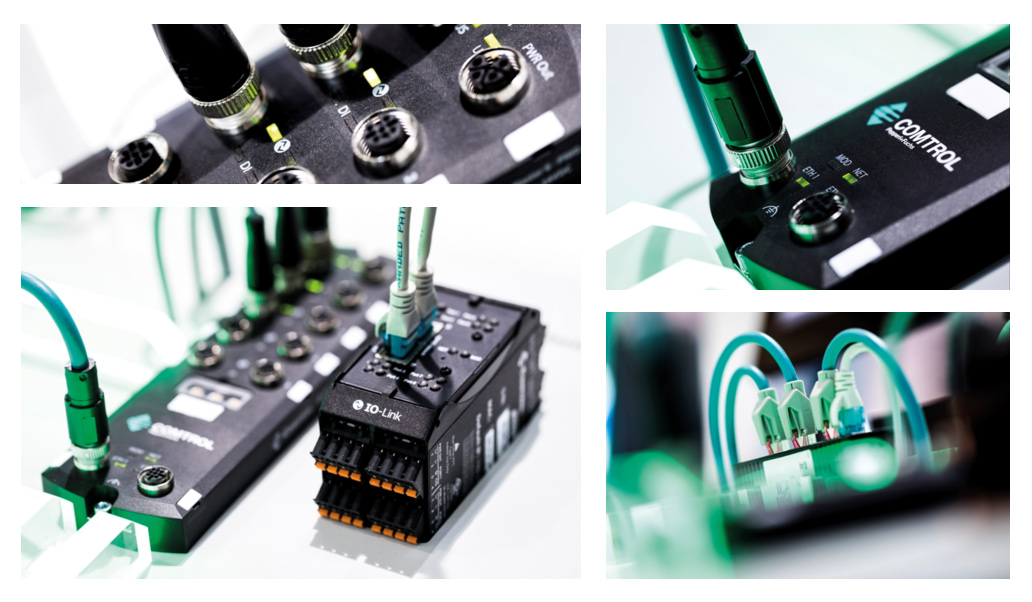

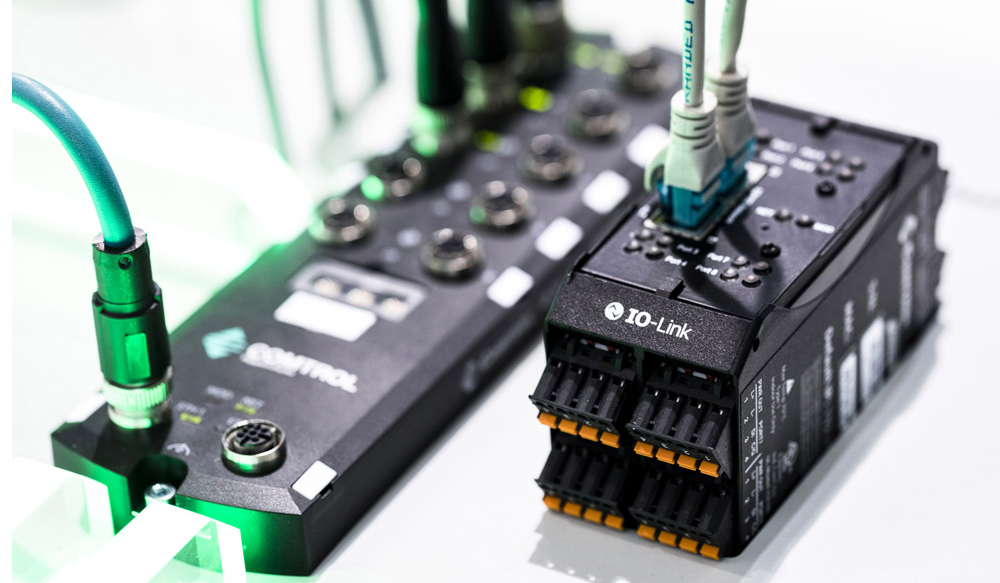

IO-Link Masters Make Factories Smarter

Industry 4.0 applications require sensors that are able to communicate with PLCs and higher-level SCADA or cloud systems. Pepperl+Fuchs IO-Link masters with MultiLink™ technology enable smarter factories.

4 Ways to Digitalize Your Factory

Digitalization can be daunting. But with the right technologies, you can prepare your factory for Industry 4.0 and build IIoT networks.

Four Scenarios for Using IO-Link Masters with OPC UA Interface

IO-Link master with OPC UA interface create a uniform basis for continuous information exchange from the field to the cloud. In this article, we will show you what applications are possible with the open data exchange standard.

8 Advantages of IO-Link

The IO-Link communication protocol is a standard interface and offers many advantages. We have picked up eight advantages of IO-Link.

Subscribe to our newsletter and receive regular news and interesting facts from the world of automation.