Ultrasonic Double Sheet Sensors with IO-Link Make Material Layer Detection Simple and Reliable

Content of This Article

- Operating Principle of Ultrasonic Double Sheet Sensors

- IO-Link Functionality—Threshold and Parameter Settings for Reliable Double Sheet Detection

- M18 or M30 Series—Which Double Sheet Sensor Suits Your Application?

- Three Application Examples for Material Layer Detection with Ultrasonic Double Sheet Sensors

- More Information

Ultrasonic Double Sheet Sensors with IO-Link Make Material Layer Detection Simple and Reliable

When it comes to reliably detecting sheets of various materials such as papers, plastic and metal foils, wood, sheet metals, or even highly reflective solar wafers in industrial processes, ultrasonic double sheet sensors offer an ideal solution. This is now easier than ever with two new series of IO-Link double sheet sensors in M18 or M30 design. The new features of the UDC-18GS-*IO-* and UDC(M)-30GS-*IO-* ultrasonic sensors series with IO-Link interface allow for improved adjustment, simple parameterization, and even more accurate detection. Learn more about the benefits of ultrasonic double sheet sensors with IO-Link interface in this blog article.

Operating Principle of Ultrasonic Double Sheet Sensors

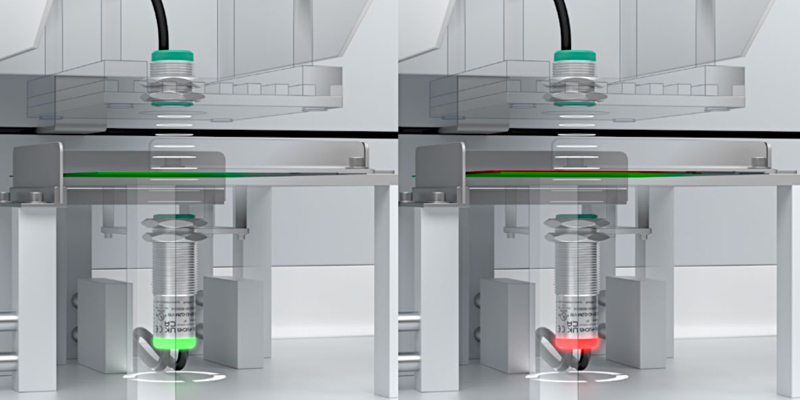

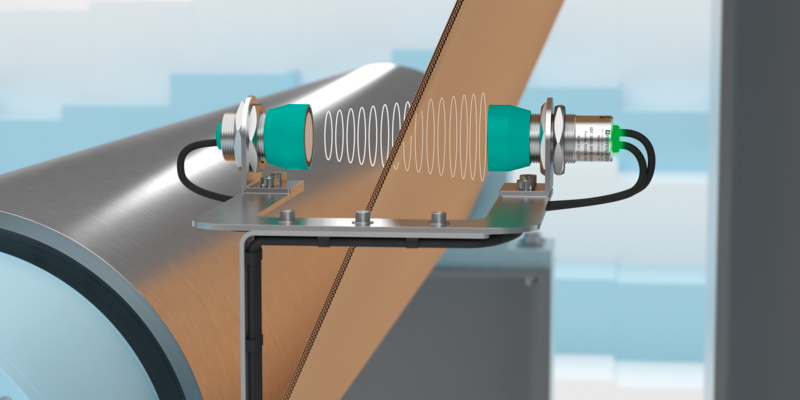

Ultrasonic double sheet sensors consist of a sensor transmitter and receiver unit that continuously monitor the material flow fed into a machine using ultrasonic pulses. Material layers between the transmitter and receiver reduce the amplitude of ultrasonic signals received and trigger a double sheet reading. Based on the measured amplitude, the sensors detect whether a single sheet of material, a double layer, or no material has been fed. Due to their insensitivity to printing, colors, and shiny surfaces, ultrasonic sensors reliably detect any type of material, offering a solution for virtually any application. During commissioning of the double sheet sensors, the integrated LEDs indicate whether the transmitter and receiver are correctly aligned. If your application requires several devices mounted close to each other, the integrated synchronization function can automatically synchronize them, eliminating possible mutual interference.

Learn about the operating principles of ultrasonic double sheet sensors in this video:

IO-Link Functionality—Threshold and Parameter Settings for Reliable Double Sheet Detection

The IO-Link double sheet sensors of the M18 and M30 series offer advanced features compared to previous models. Users can now access all sensor parameters as well as diagnostic and process data via the IO-Link interface, opening up new possibilities in machine analysis and predictive maintenance. Real-time monitoring of process data makes it easier to find the ideal threshold settings in the sensor depending on the material and its specific damping behavior. This enables the sensor parameters to be set correctly, avoids false detections, and increases machine availability.

The sensors are equipped with three predefined sets of thresholds and can therefore reliably distinguish between one layer and multiple layers of any type of material. When particularly thick and thin materials need to be detected in one application, the threshold values can be adjusted by dynamically switching between three different sets:

Threshold set 1: “Normal” materials

Threshold set 2: “Normal” to “very thick” materials

Threshold set 3: “Very thin” to “normal” materials

Learn about the three options for easy parameterization of double sheet sensors M18 and M30 series in this video:

Alternatively, users can also adjust the double sheet sensors very precisely to a specific material via teach-in. In addition, various parameters can be configured specifically for the application via the IO-Link interface. These include, among others:

- Averaging of the Measured Values

With this function, the measured values are already filtered and averaged in the sensor to allow a very precise measurement result and therefore a very reliable detection output. - Output Logic

Users can choose between the “normally open” (NO) or “normally closed” (NC) output logic. - Output Threshold

The threshold values of the threshold sets can also be set directly to the amplitude values that may be specifically required in the application. This allows the sensor to be adapted extremely precisely to application-specific conditions.

The states of all outputs, the current amplitude value, and the threshold value set used for the evaluation are transmitted via the cyclical IO-Link process data. This provides users with an overview and all relevant information at all times.

Ultrasonic double sheet sensors with IO-Link interface in M18 and M30 design ease layer detection of any kind of material.

M18 or M30 Series—Which Double Sheet Sensor Suits Your Application?

Pepperl+Fuchs offers the smart ultrasonic double sheet sensors with IO-Link in the M18 and M30 series, which can be differentiated according to the material to be detected and its damping properties:

Double Sheet Sensors of M18 Series

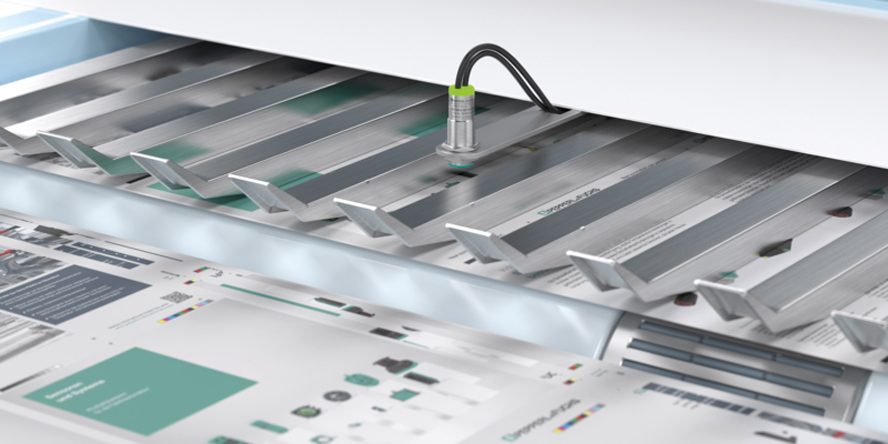

The double sheet sensors of the M18 series (UDC-18GS-*IO-*) are ideal for detecting materials such as paper, cardboard, simplex corrugated board, plastic films, and electrode foils. Even thin metal sheets up to approx. 0.4 mm thickness can be monitored on double sheets. They M18 devices are used, for example, in printing presses or the packaging industry to detect double sheets in order to prevent misprints and paper jams. In battery manufacturing, the devices reliably monitor the feeding of electrode foils.

Double Sheet Sensors of M30 Series

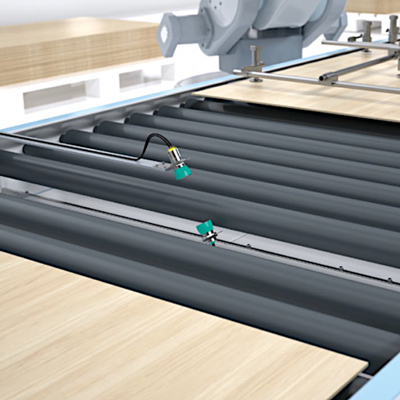

The M30 series double sheet sensors (UDC-30GS-*IO-* and UDCM-30GS-*IO-*) are designed for very thick or highly damping materials, such as duplex corrugated paper, glass sheets, wood, or metal plates. The sensors reliably detect when the gripper robot accidentally feeds two sheets or plates stuck together into the machine. This prevents damage to the tools and ensures more reliable processes.

Three Application Examples for Material Layer Detection with Ultrasonic Double Sheet Sensors

A single M18 series ultrasonic double sheet sensor is sufficient for reliable detection of multilayered paper products. Learn more

The M30 series IO-Link ultrasonic double sheet sensor ensures the correct infeed of wood or sheet metal into machines. Learn more

The M18 series ultrasonic double sheet sensor reliably prevents infeed of double electrode sheets in battery production. Learn more

More Information

- Product Selection: IO-Link Double Sheet Sensors

- Overview Brochure: Ultrasonic Double Sheet Sensors of the M18 and M30 Series

- Free Download: Ultrasonic Sensor Technology Guides

Subscribe to our newsletter and receive regular news and interesting facts from the world of automation.