Knowledge Base

Pepperl+Fuchs offers a large portfolio of devices, solutions, and technologies for a wide variety of industrial applications and explosion protection. But have you ever wondered what is actually behind certain technologies or how individual products vary from one another? In the Pepperl+Fuchs knowledge base section, we answer general questions and provide assistance on our technologies and products.

Knowledge Base

Pepperl+Fuchs offers a large portfolio of devices, solutions, and technologies for a wide variety of industrial applications and explosion protection. But have you ever wondered what is actually behind certain technologies or how individual products vary from one another? In the Pepperl+Fuchs knowledge base section, we answer general questions and provide assistance on our technologies and products.

Vibration Diagnostics with Raw Acceleration Data Sensors

In vibration diagnostics, there are two different methods for monitoring the performance and condition of machines: While unbalance measurement based on Root Mean Square (RMS) sensors primarily aims at general machine monitoring, frequency analysis based on raw acceleration data enables a more in-depth analysis of vibration behavior.

ASi-3, ASi-5, and IO-Link: A Comparison of Three Communication Protocols

As simple and comparatively cost-efficient wiring technologies for sensors and actuators in the field, AS-Interface and IO-Link combine high functionality, flexibility, and reliability. In this blog article, learn where to use ASi-3, ASi-5 and IO-Link, and what makes these communication protocols so special.

When Do I Use Which Surge Protector? Three Solutions at a Glance

Pepperl+Fuchs offers the right surge protection barriers for every infrastructure, whether for signal lines, supply lines, fieldbus, or Ethernet-APL applications.

Energy Efficiency and Cost Savings: PS1000 Power Supplies in Industrial Applications

Sustainable, energy-efficient production processes are becoming increasingly important in industrial applications worldwide. Learn more about the importance of the efficiency and sustainability for power supplies and how the Pepperl+Fuchs PS1000 product family contributes to it.

Intrinsic Safety Type of Protection: A Fundamental Overview

Learn more about intrinsic safety (Ex i) type of protection, it's main purpose, application and advantages. We take a look at the classification system, the different levels of protection, and three important terms used to describe intrinsic safety.

Multipixel Technology vs. Pulse Ranging Technology—a Comparison of Two Photoelectric Measuring Principles

Have you ever wondered what is the difference between Multipixel Technology (MPT) and Pulse Ranging Technology (PRT)? Find out how photoelectric sensors with MPT and PRT work and for which applications the respective technologies are suitable.

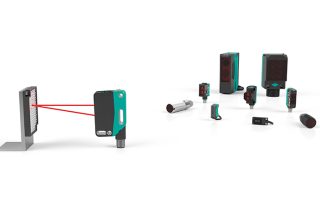

Frequently Asked Questions about Retroreflective Sensors and Reflectors

We answer the most frequently asked questions about the use of retroreflective sensors and what type of reflector is suitable for your application.

What Is Purging and Pressurization?

Purging and pressurization is a safe and cost-effective type of explosion protection that allows electrical equipment to be used in a standard enclosure in potentially explosive atmospheres. Find out more about the Ex p type of protection and the functional principle of pressurized enclosures in explosive gas and dust atmospheres in our blog article.

Ethernet-APL Simply Explained—How Parallel Communications Work

Ethernet Advanced Physical Layer, Ethernet-APL for short, is the physical layer for transmitting data into the field of process plants. Learn how parallel communication works today and what possible options there are to access data.

Sinking and Sourcing with Smart Transmitter Power Supply for Analog Input Applications

When selecting an intrinsic safety barrier for an analog input application, one of the biggest issues customers face is differentiating between sinking and sourcing. These terms are used to refer to where the power of the current signal is coming from. Not sure what they mean? Keep reading.

Data Matrix Positioning System PXV versus PCV—What’s the Difference?

Pepperl+Fuchs released the next generation of Data Matrix positioning—the PXV series. How does this Data Matrix positioning system differ from the proven PCV absolute positioning system?

What is Industry 4.0?

What exactly means Industry 4.0? In this blog post, we give an overview of the past Industrial Revolutions that have brought us to this point and outline how Pepperl+Fuchs is involved in Industry 4.0.

Subscribe to our newsletter and receive regular news and interesting facts from the world of automation.