Frequently Asked Questions about Retroreflective Sensors and Reflectors

Content of This Article

- What is a retroreflective sensor?

- My retroreflective sensor does not detect a reflective or shiny object. How can I correct this?

- I am looking for a retroreflective sensor for a counting application that detects clear glass bottles on a conveyor belt. What would be the best option?

- What is foreground suppression in retroreflective sensors?

- I am looking to use one sensor to detect multiple objects of different shapes and sizes but do not have the budget for a thru-beam light grid. Are there any options for me?

- What is the best type of reflector to use with retroreflective sensors?

- Due to size constraints, I cannot integrate a reflector into my application. I have replaced the reflector with a piece of reflective tape but the sensor does not recognize the tape. What can I do?

- Are there any reflector options for extreme temperatures?

- Are there special reflectors for use in the food industry?

- More Information

Frequently Asked Questions about Retroreflective Sensors and Reflectors

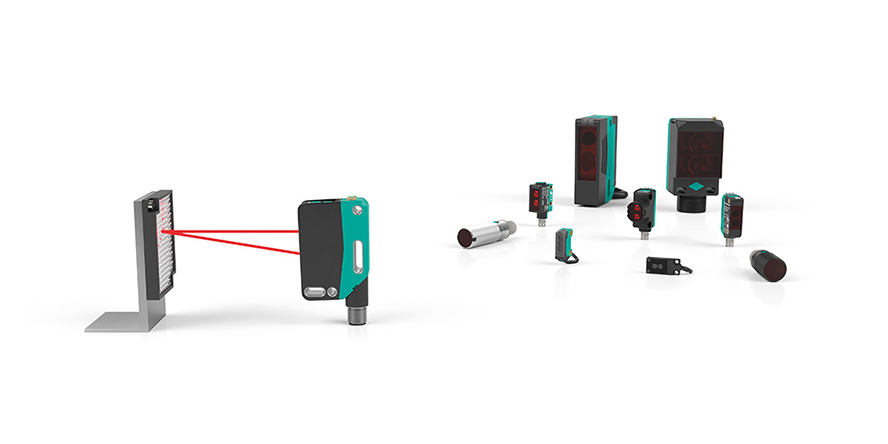

Retroreflective sensors from Pepperl+Fuchs are available in different versions—from models with polarization filters to sensors for detecting transparent objects to variants with foreground suppression and area sensor versions. Typical retroreflective sensors offer a larger detection range compared to diffuse mode sensors. An object is detected when it interrupts the light beam between the sensor and a reflector.

In this blog article, we answer the most frequently asked questions we receive about the use of retroreflective sensors and reflectors.

What is a retroreflective sensor?

Retroreflective sensors are photoelectric sensors. They consist of an emitter and receiver in a single housing. The light beam generated by the emitter is reflected back to the receiver by a reflector. Whenever this light beam is obstructed, the state of the sensor’s output signal changes and a switching operation is triggered.

My retroreflective sensor does not detect a reflective or shiny object. How can I correct this?

A common problem with retroreflective sensors is that a shiny or reflective object cannot be reliably detected in an application. The workaround in such cases is to use a retroreflective sensor with a polarization filter in conjunction with a corner cube reflector. The object is reliably detected due to the different reflection of a triple mirror reflector compared to a reflective surface.

I am looking for a retroreflective sensor for a counting application that detects clear glass bottles on a conveyor belt. What would be the best option?

The detection of transparent objects requires retroreflective sensors that can detect even small changes in the amount of light. When a transparent object such as a glass bottle passes the sensor, the device detects small changes in light and triggers the output signal. With many of these sensors, the percentage of this change can be adjusted so that they can also be used with colored glass or semi-transparent materials. Pepperl+Fuchs generally identifies retroreflective sensors for glass detection with a G (glass) in the nomenclature.

What is foreground suppression in retroreflective sensors?

With foreground suppression, optical apertures are added in front of the emitter and receiver to restrict the active detection range of the retroreflective sensor. These apertures only allow the detection of light that is reflected directly at the receiver. This setup creates a defined area in front of the sensor in which the sensor does not falsely detect glossy/shiny targets as reflectors. A common application of foreground suppression is the detection of a shrink-wrapped pallet: the reflective properties of the shrink-wrap are ignored by the sensor and only the objects behind it are detected.

I am looking to use one sensor to detect multiple objects of different shapes and sizes but do not have the budget for a thru-beam light grid. Are there any options for me?

The RLG28 Series retroreflective area sensor has multiple light beams in one housing which are aimed at a reflector. This sensor provides more sensing coverage than a single-beam retroreflective sensor at a lower cost than a thru-beam type light grid. The RLG28 area sensor provides reliable detection of objects with different contours, positions, shapes, and textures.

What is the best type of reflector to use with retroreflective sensors?

This question can be answered in a few different ways depending on the type of retroreflective sensor:

- Corner-cube plastic reflectors reflect the light back to the sensor and can be used with all types of retroreflective sensors. A corner-cube style reflector must be used for retroreflective sensors with polarization filters.

- The use of a retroreflective sensor with polarization filter in conjunction with a corner cube reflector is recommended for detecting reflective objects.

- If the sensor has a laser light source and a short sensing range, a corner cube reflector with a microstructure should be used due to the very small light spot.

- A reflector is specified as a reference object in the datasheet for each retroreflective sensor. All technical specifications are based on this reflector, including the maximum operating range. If a smaller reflector is used, the operating range of the sensor is reduced.

Due to size constraints, I cannot integrate a reflector into my application. I have replaced the reflector with a piece of reflective tape but the sensor does not recognize the tape. What can I do?

Thin reflective tape (also known as optical reflective film) is an option for applications in which plastic reflectors can only be used to a limited extent due to their dimensions. However, this reflective tape does not have the same reflective properties as a reflector. When using reflective tape, less light is returned to the sensor, which reduces the overall sensing range. The range listed in the sensor datasheet applies to reflectors. When using reflective tape, the range is reduced by approx. 50 %. Only reflective tapes with a micro-triplet structure should be used, as only these are suitable for retroreflective sensors with polarization filters.

Are there any reflector options for extreme temperatures?

Pepperl+Fuchs offers reflectors for both extreme heat and extreme cold. For high-temperature applications, there are options that can be used from 120 °C to 500 °C. For extreme cold, Pepperl+Fuchs offers a reflector with a heating element that prevents condensation or ice from forming on the reflective surface and causing malfunctions.

Are there special reflectors for use in the food industry?

Devices used in the food and beverage industry require protection class IP69K, as the equipment there often has to be cleaned at high temperatures and under high pressure. Both sensors and reflectors must also be resistant to chemicals, as they are constantly exposed to cleaning agents and disinfectants. Pepperl+Fuchs offers washdown-rated, chemical-resistant reflectors with IP69K degree of protection and resistance to chemical substances. These reflectors are available in a variety of sizes.

More Information

Subscribe to our newsletter and receive regular news and interesting facts from the world of automation.