We are pleased to welcome you to our blog. Here you will find useful information, applications, and guidance on the topics of automation, industrial sensors, and explosion protection.

Welcome to our blog. Here you will find current articles on the topics of industrial automation and sensor technology.

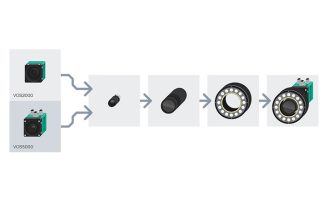

How to Assemble the VOS 2-D Universal Vision Sensor for Your Application

The VOS 2-D universal vision sensor portfolio offers high scalability on the hardware side, from simple vision applications to more demanding tasks. In this blog article, you will get an overview of the VOS hardware components as well as the criteria for the optimal mix so that you can tailor your vision sensor exactly to your application.

Mounting Dual Inductive Sensors on Manual Valves

The dual inductive sensors from Pepperl+Fuchs make it possible to monitor the position of the valves in your process plant at any time. But what is the best way to mount the sensors? This blog article will help you decide on the right accessories.

4 Sensing Methods to Verify Part Ejection in Metal Forming

When punching or notching metal strips, unwanted material must be cleared to prevent damage. Learn four sensing methods to verify part ejection in metal forming.

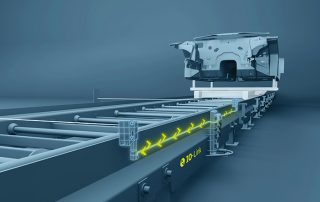

4 Sensor Applications to Control a Metal Coil Feeding Line

Controlling a metal coil feeding line with the right sensor technology minimizes machine downtime while maximizing part quality and yield. Get to know different sensor principles in four applications to control a metal coil feeding line.

What Is Purging and Pressurization?

Purging and pressurization is a safe and cost-effective type of explosion protection that allows electrical equipment to be used in a standard enclosure in potentially explosive atmospheres. Find out more about the Ex p type of protection and the functional principle of pressurized enclosures in explosive gas and dust atmospheres in our blog article.

IO-Link Device Offline Parameterization Using PACTware

When connected to an IO-Link master, IO-Link devices offer a variety of benefits to the control systems in a plant, such as online configuration and parameterization, simplified device exchange, and even data acquisition via OPC UA and MQTT. For commissioning and test reasons, however, you may wish to configure and parameterize an IO-Link device outside the plant. This blog article supports you in offline parameterization of IO-Link devices using PACTware.

Subscribe to our newsletter and receive regularly news and interesting information around the world of automation.