Intrinsic Safety Type of Protection: A Fundamental Overview

Content of This Article

Intrinsic Safety Type of Protection: A Fundamental Overview

The term “intrinsically safe” is often used in industries dealing with flammable or combustible materials that result in hazardous area classifications. Although intrinsic safety is a valid and safe type of protection for equipment used in these areas, the term “intrinsically safe” is often incorrectly used to refer to equipment suitable for use in hazardous areas in general, rather than just those protected by intrinsic safety. As there are many different types of protection that can be used to protect electrical equipment for use in potentially explosive atmospheres, it is important to understand that intrinsic safety (“Ex i”) is a special protection concept, and due to the way this type of protection works, only certain types of equipment are typically designed or even possible to be intrinsically safe. Find out more about important terms and different levels of protection of intrinsic safety in this blog article.

Main Purpose of the Intrinsic Safety Type of Protection

Intrinsic safety (Ex i), like all other protection concepts, aims to reduce the risk of fire or explosion in a hazardous area. It is therefore important to understand how all protection concepts generally work towards risk reduction. For atmospheres that are hazardous due to the presence of gases or vapors, three key components are required for a risk to exist: an ignition source, an oxidizer, and a fuel. These three elements are usually represented in a triangular relationship and referred to as the combustion triangle. If the triangle can be broken up or contained, the risks can be reduced to a tolerable level. In atmospheres that have a dust hazard, the explosion risk comprises two additional elements and is often represented as the “dust explosion pentagon”. The additional elements are the suspension of the dust and the confinement of the dust.

Most types of protection attempt to somehow eliminate or separate the relationship between these elements. When we talk about the intrinsic safety type of protection, we are specifically targeting the ignition source portion of the relationship by limiting the amount of energy within a circuit to a non-ignitable level. By properly eliminating the ignition source, the required risk reduction is achieved and the added safety desired can be realized.

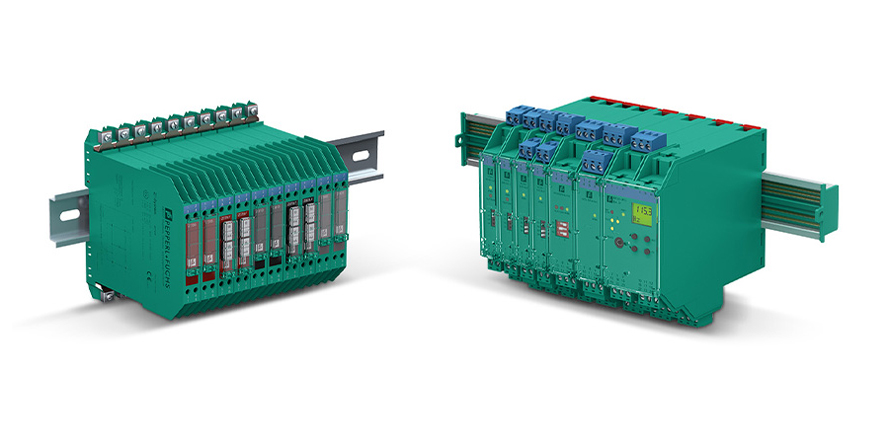

Pepperl+Fuchs offers the largest portfolio of intrinsic safety barriers of its kind, covering almost all applications in the process industry. The K-System isolated barriers ensure intrinsically safe circuits by limiting the amount of energy (current and voltage) supplied and electrically isolating the non-intrinsically safe circuit on the control side.

Application and Advantages of Intrinsic Safety

Since intrinsic safety aims to limit the amount of energy within a circuit, only low energy systems or low energy signals can be considered. These primarily include sensors, actuators, and the control signals associated with them, but can also include portable and handheld devices such as measurement equipment, smartphones, and tablets. From simple point-to-point connections to digital process automation with Ethernet-APL, intrinsic safety is easy to implement.

One big advantage of intrinsic safety is that it is possible to design intrinsically safe equipment to cover all explosion-hazardous areas worldwide, for both gas/vapor and dust hazards, making it a very versatile type of protection. Intrinsic safety is also the only type of protection that allows terminals to be opened in potentially explosive areas, or intrinsically safe equipment to be removed and replaced with equivalent devices. Troubleshooting or repairs can also be carried out under voltage without shutdowns of the plant.

Classification System for Hazardous Areas and Ex i Levels of Protection

There are two systems for classifying hazardous areas around the world:

- the Class/Division system, which is predominant in the US and Mexico and still quite popular in Canada and other South American countries

- the Zone system, which is recognized and used in all countries and regions

Intrinsically safe devices and associated apparatus are classified according to their level of protection:

- Ex ia is suitable for use in Zone 0, 1, and 2, Division 1: ignition protection by two protective measures offers a very high level of safety (safe normal operation even in the event of two faults)

- Ex ib is suitable for use in Zone 1 and 2, Division 2: ignition protection by one protective measure offers a high level of safety (safe normal operation even in the event of one fault)

- Ex ic is suitable for use in Zone 2, Division 2: ignition protection during normal operation (safe during normal operation)

Understanding Three Important Terms Used to Describe Intrinsic Safety

When it comes to the design of equipment or installations that use intrinsically safe equipment, there are three specific terms that are used to describe the basic safety components. Understanding these terms is a first step in understanding an intrinsically safe system or installation as a whole.

Intrinsically Safe Apparatus

This is electrical equipment that is fully protected by intrinsic safety, for example a field device such as a sensor or transmitter. This can also be a stand-alone device such as a mobile device, for example a handheld, smartphone, or tablet.

Associated Apparatus

This is electrical equipment or a device that contains both intrinsically safe circuits and non-intrinsically safe circuits. These are the devices that interface with the intrinsically safe apparatus to ensure its safety. This can be thought of as a barrier or similar device that is designed to limit the energy to the field. There are many devices of this type that are designed for installation in a lower risk hazardous area, such as Division 2 or Zone 2/22, but they can also be designed for installation in a non-hazardous area only, with their output signals going to the intrinsically safe apparatus in the hazardous area.

Intrinsically Safe Circuit

This is an overall circuit that is not capable to be a source of ignition due to sparks or thermal effects. This generally refers to the entire electrical circuit, but in most installations it refers to the connection of the apparatus to the associated apparatus, taking into account all electrical connections and the wire to complete the circuit. Before commissioning an intrinsically safe circuit for use in a hazardous area, the intrinsic safety must be verified and documented in accordance with the relevant local requirements. In the USA this would be the NEC ®, in Canada the CE Code, and in many other countries IEC 60079-14 or a local/national version of this standard.

More Information

You may also be interested in

- How to Easily Implement Intrinsic Safety with Ethernet-APL

- Smart-Ex® 03 Intrinsically Safe Smartphone with All-Around USB-C Interface

- SIL 3 Current Drivers for Intrinsically Safe Signals – Minimal Hardware Costs and Improved Test Intervals

- Ensuring Product Safety in Hazardous Areas with Intrinsic Safety

Subscribe to our newsletter and receive regular news and interesting facts from the world of automation.