We are pleased to welcome you to our blog. Here you will find useful information, applications, and guidance on the topics of automation, industrial sensors, and explosion protection.

Welcome to our blog. Here you will find current articles on the topics of industrial automation and sensor technology.

RFID in Explosion-Hazardous Areas: Three Examples from the Field

In this blog article, you will gain insight into three application examples that will help you understand the successful and safe use of RFID in hazardous areas.

Machine Guard Monitoring in the Food Processing Industry

In the food processing industry, size reduction equipment is widely used to process foods from their original shapes and sizes into their final forms, like shredded cheese, sliced and diced vegetables, potato chips, and peanut butter. Pepperl+Fuchs offers a safety system for machine guard monitoring combined of a safety monitor and magnetic field sensors for use in hazardous areas.

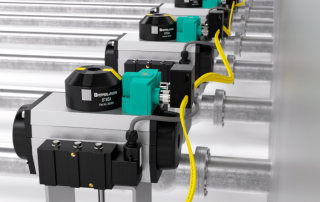

Valve Position Feedback with Dual Inductive Sensors

Dual inductive sensors from Pepperl+Fuchs ensure reliable and fault-free valve position feedback—even under the most demanding environmental conditions. Find out in this blog article which dual inductive sensor is the optimal solution for your process application.

How to Decode RFID Tags (HF)

Pepperl+Fuchs’ RFID read/write heads can read any RFID tags and any RFID system can read Pepperl+Fuchs’ RFID tags made to the international standards ISO/IEC 15693 and ISO/IEC 18000-3. In this blog article, we explain how to decode HF RFID tags to configure your HF RFID system.

Metal Data Matrix Code Bars—the Rugged Solution for Your Positioning System

For PGV and PXV positioning systems in harsh industrial environments, Pepperl+Fuchs has developed Data Matrix code bars made of printed aluminium. In this blog article, you will learn how these code bars can make your positioning solution more durable and rugged.

Durable and Easy to Handle M8 and M12 Connectors—for Simplified Installation and Maintenance

M8 and M12 connectors are the standard in factory automation. Due to numerous technical optimizations, these connectors provide you with highly robust and durable connection technology. Learn more about the M8 and M12 connectors from Pepperl+Fuchs!

Subscribe to our newsletter and receive regularly news and interesting information around the world of automation.