Industrial Sensors

Find out more about industrial sensors and various operating principles for automating your plant on the Pepperl+Fuchs blog. We highlight their respective advantages in a variety of applications and support you in selecting the right sensor, identification, or positioning system. Dive deeper into the world of sensors, industrial communication, and the integration into your plant.

Industrial Sensors

Find out more about industrial sensors and various operating principles for automating your plant on the Pepperl+Fuchs blog. We highlight their respective advantages in a variety of applications and support you in selecting the right sensor, identification, or positioning system. Dive deeper into the world of sensors, industrial communication, and the integration into your plant.

Vision Sensors—Use Cases for Industrial Vision in the Automotive Industry (Part 4)

Learn three examples and the advantages of vision sensors in the automotive industry. The detection of fasteners in automotive construction, optical identification in the high-temperature range, and the detection of components in car body construction are only a few of the use cases for industrial vision in the automotive industry.

Vision Sensors—Use Cases for Industrial Vision in Material Handling (Part 3)

Whether it is the adjustment of automated-guided vehicles, the positioning of stack carriers, or the removal control during order picking processes—material handling faces a multitude of challenges. To meet these, Pepperl+Fuchs offers a broad portfolio of vision sensors in material handling. Learn more about three application examples from storage and material handling in this blog article and discover the solution for your industrial vision task.

Vision Sensors—Three Examples for Industrial Vision in Material Handling (Part 2)

Whether control, positioning, or monitoring—the tasks of vision sensors in storage and material handling could hardly be more diverse. Pepperl+Fuchs offers a comprehensive portfolio in the area of industrial vision for the various requirements of these tasks. In this blog article, you will gain insights into three applications for vision sensors in material handling and learn what advantages the products used can also offer for your application.

Vision Sensors—Three Examples for Industrial Vision in the Automotive Industry (Part 1)

Whether for automatic component inspection, code reading on vehicle components, or the positioning of electric monorail systems—the application areas of vision sensors are as diverse as the portfolio of industrial vision. Learn more about three application examples of vision sensors in the automotive industry.

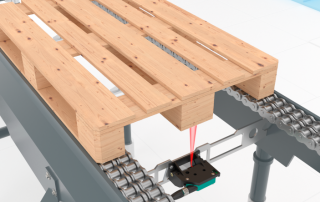

Pallet Detection on Roller Conveyor Systems—Optical or Ultrasonic?

Until recently, customized solutions were required to detect different pallet types on roller conveyor systems. The Pallet Detector from Pepperl+Fuchs now allows flexible switching between two technologies. This enables different types of pallets to be detected using a single solution. Find out which version is most suitable for which type of pallet!

Changeover from ASi Gateway K20 to KE5: IIoT-Ready In 3 Steps

The multiprotocol-capable AS-Interface gateway type KE5 makes your AS-Interface network ready for IIoT applications. Learn how to switch from the legacy type K20 ASi gateway with PROFINET interface to the IIoT-ready ASi-3 gateway KE5 in three steps.

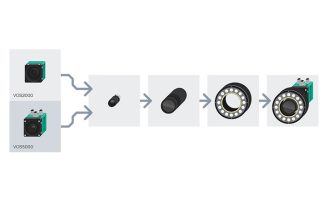

How to Assemble the VOS 2-D Universal Vision Sensor for Your Application

The VOS 2-D universal vision sensor portfolio offers high scalability on the hardware side, from simple vision applications to more demanding tasks. In this blog article, you will get an overview of the VOS hardware components as well as the criteria for the optimal mix so that you can tailor your vision sensor exactly to your application.

4 Sensing Methods to Verify Part Ejection in Metal Forming

When punching or notching metal strips, unwanted material must be cleared to prevent damage. Learn four sensing methods to verify part ejection in metal forming.

4 Sensor Applications to Control a Metal Coil Feeding Line

Controlling a metal coil feeding line with the right sensor technology minimizes machine downtime while maximizing part quality and yield. Get to know different sensor principles in four applications to control a metal coil feeding line.

Choosing the Right BlueBeam Rotary Encoder for Your Application

Pepperl+Fuchs BlueBeam rotary encoders offer high accuracy, which is particularly useful in applications where even minimal deviations lead to reduced performance. BlueBeam rotary encoders from Pepperl+Fuchs offer a unique level of precision—but which version is best suited for your application? This blog article will give you a concise overview.

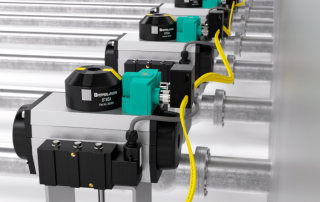

Valve Position Feedback with Dual Inductive Sensors

Dual inductive sensors from Pepperl+Fuchs ensure reliable and fault-free valve position feedback—even under the most demanding environmental conditions. Find out in this blog article which dual inductive sensor is the optimal solution for your process application.

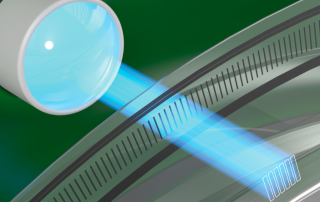

Metal Data Matrix Code Bars—the Rugged Solution for Your Positioning System

For PGV and PXV positioning systems in harsh industrial environments, Pepperl+Fuchs has developed Data Matrix code bars made of printed aluminium. In this blog article, you will learn how these code bars can make your positioning solution more durable and rugged.

Subscribe to our newsletter and receive regular news and interesting facts from the world of automation.