Brownfield Digitization Made Easy: Ethernet-APL Meets Remote I/O

Content of This Article

Brownfield Digitization Made Easy: Ethernet-APL Meets Remote I/O

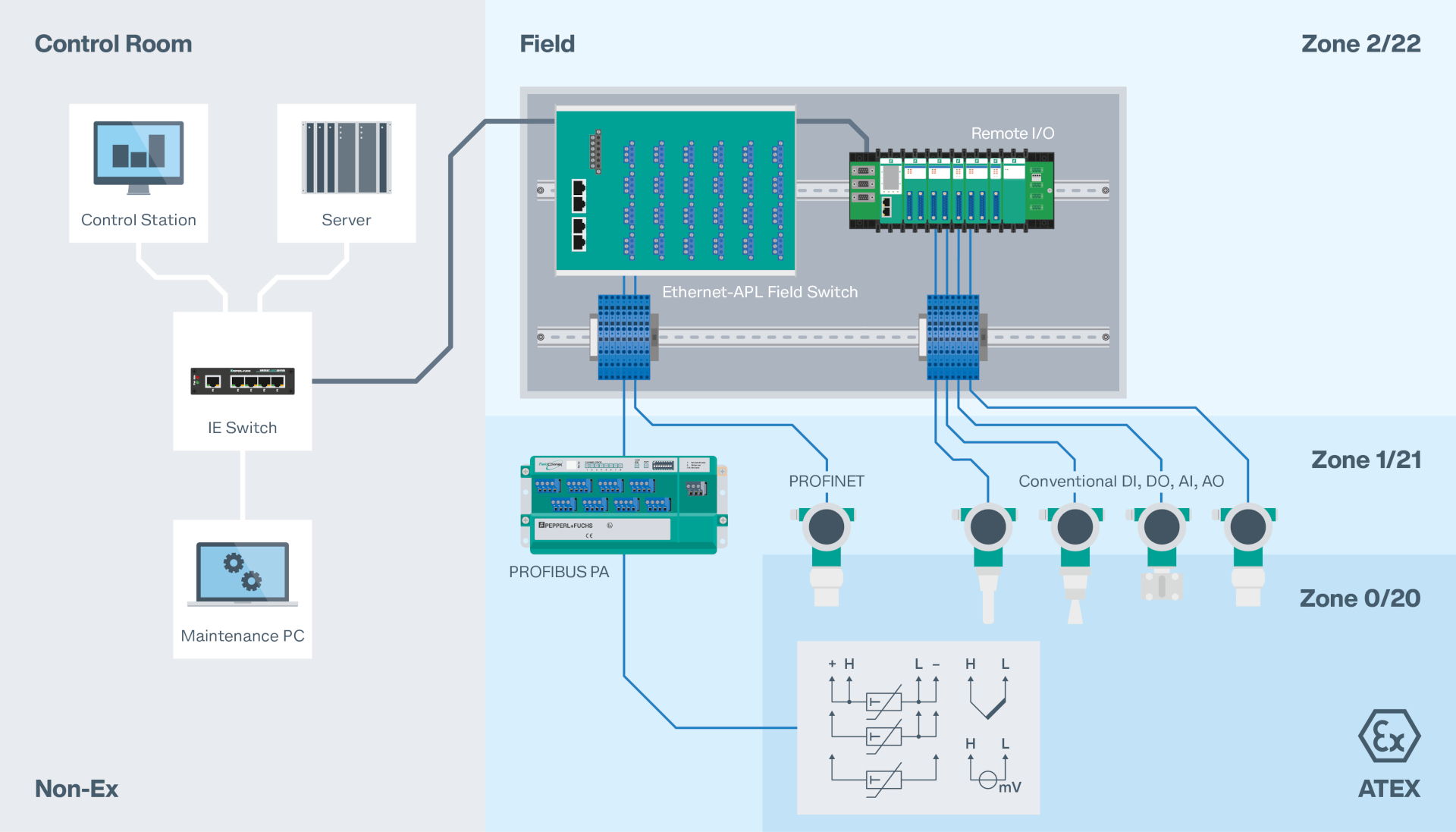

The process industry is currently under considerable pressure: rising energy and raw material prices as well as stricter regulatory environmental and occupational health and safety requirements (e.g., RED III, IED 2.0, EU Regulation 2023/1230) are forcing plant operators to make their systems more efficient, sustainable, and safe. At the same time, customers and markets expect more flexibility, transparency, and quality in production. However, many of the older existing plants are not prepared for this balancing act, which would actually require a comprehensive modernization as such a complete rewiring and conversion to digital field devices is usually not a financially or logistically feasible option with several thousand inputs and outputs. If a control system with PROFINET support is already in operation, it is worth considering an iterative approach and a combination of remote I/O systems and Ethernet-APL rail field switches in such cases.

Ethernet-APL: The Door Opener for IIoT in Process Plants

Ethernet-APL enables operators to run a continuous communication network based on standard Ethernet right into explosion-hazardous areas. The Ethernet-APL rail field switch converts the standard Ethernet to a two-wire, twisted pair Ethernet where both power and data can be transmitted, which significantly streamlines the infrastructure and at the same time allows the connection of modern, intelligent field devices. These devices provide far more information than just their actual measured value: they can provide status data, perform self-diagnostics, and integrate seamlessly into asset management systems. Furthermore, Ethernet-APL enables data transfer rates of up to 10 Mbit/s, a significant increase compared to conventional fieldbus systems. At the same time, it supports cable lengths of up to 1,000 meters on the trunk or 200 meters on spur lines, thus also setting standards in terms of range. Ethernet-APL is therefore the leading technology for new measuring points or extensions to existing systems, paving the way towards end-to-end digitization and laying the foundation for predictive maintenance and transparent system monitoring.

Remote I/O: The Link Between the Technology Worlds

At the same time, it would be unrealistic to expect that all existing sensors and actuators can be replaced in the short term: There is often the hurdle that not all field devices and cables are Ethernet-APL-compatible and laying new cables would entail sensitive costs. This is exactly where remote I/O systems come into play. They act as a link between the conventional signal world (i.e., analog 4–20 mA circuits or HART signals, discrete inputs, or NAMUR signals) and the modern Ethernet architecture. Analogue and discrete field devices retain their existing cabling, while the remote I/O system receives the signals, digitizes them, and forwards them to the control system via an Ethernet-APL rail field switch and an existing PROFINET network. This allows older measuring points to be integrated into a future-oriented system without requiring major changes to the existing infrastructure.

Integrated Brownfield Solutions from a Single Source

For this type of gradual digitization in brownfield systems to succeed, a partner is required who is proficient in both the classic signal world and the latest Ethernet technologies. As a market leader and pioneer in the field of electrical explosion protection, Pepperl+Fuchs combines its own Ethernet-APL rail field switches, remote I/O systems, power supplies, and cable glands with other required components in its global Solution Engineering Centers (SECs) to create ready-to-use, customer-specific complete solutions. With decades of experience in explosion protection, we support system digitization in a way that is both practical and economical. Our approach minimizes risks and avoids the high costs associated with complete rewiring.

Ethernet-APL and Remote I/O Combination Solutions at a Glance

- No complete rewiring necessary; existing 2-wire lines remain usable

- Economic integration of existing instrumentation

- Digital evaluation of all signals for optimized asset management

- Increased system availability and reduced maintenance costs

- Fast commissioning due to pre-assembled components in fully certified complete solutions for Zone 2 and 22

- Compatible and future-oriented for hybrid systems

- Extended fault protection and state-of-the-art diagnostic options

Subscribe to our newsletter and receive regular news and interesting facts from the world of automation.