Diagnostic Functions of Isolators Explained—Five Frequently Asked Questions

Content of This Article

Diagnostic Functions of Isolators Explained—Five Frequently Asked Questions

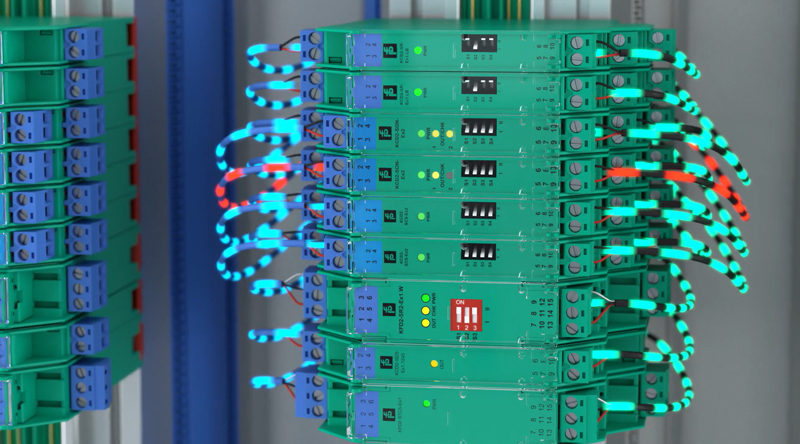

Isolators enable the conversion of electrical signals and ensure galvanic isolation between input and output signals in all industrial applications. Signal conditioners are used for safe signal transmission between field devices in the safe area and the control and management system. Intrinsic safety barriers ensure the intrinsic safety of circuits in explosion-hazardous areas and limit the energy fed into the circuit so that no sparks or dangerous heating can occur. But the devices offer much more than that: Modern isolators are equipped with a variety of diagnostic functions to monitor the system status, detect supply, line, and function faults, and ensure compliance with safety standards.

In this blog article, we answer five frequently asked questions about the various diagnostic functions of isolators, explain their functionality, and show why they are indispensable for reliable operation in demanding industrial environments and explosion-hazardous areas.

1. Line Fault Detection (LFD) vs. Line Fault Transparency (LFT): What Do They Mean and How Do the Two Diagnostic Functions Differ?

Isolators with Line Fault Detection (LFD) actively monitor signal lines for interruptions or short circuits. If a fault is detected, such as a broken wire or a connection to ground, the system responds with a diagnostic signal or fault message. This function is ideal for applications where safety, system integrity, or preventive maintenance are critical. Line fault detection helps to identify wiring problems at an early stage and enables rapid troubleshooting. If a fault is detected, this signal can be connected to a digital input card on the control system via a fault relay, enabling remote monitoring of line faults. However, this remote monitoring requires additional I/O channels at the controller.

Isolators from Pepperl+Fuchs detect line faults in the signal circuit without additional wiring.

Line Fault Transparency (LFT) uses the diagnostic functionality of line fault detection (LFD) and combines this fault message at the same terminal point as the control signal. It makes the line fault signal available for every field connection without requiring additional wire connections at the I/O card. This saves space and additional hardware costs. The only requirement is that the I/O card must also support this diagnostic function in order to utilize LFT. When using LFT, the control-side connection changes the output impedance (high or low) outside its normal parameters. The I/O card must acknowledge this impedance change and report it as a fault.

Watch the video and learn more about line fault transparency:

2. What Does Test Pulse Immunity of Isolators Mean and Why Is It Important?

In safety systems, test pulse immunity refers to the ability of an isolator module to respond correctly when a controlled test signal or test pulse is applied to the control loop. This test ensures that the device is connected correctly, the loop is functioning as intended, and that the isolator itself is operating reliably under normal conditions. It is an important check of system integrity and proper device functionality.

In hazardous area installations, intrinsic safety barriers play a key part in limiting the amount of energy within a circuit to prevent ignition by sparks or thermal ignition sources. Many control systems in these environments use short voltage pulses, called test pulses, to detect faults such as wire breaks or short circuits. While useful for diagnostics, these pulses can cause interference with connected devices, including intrinsic safety barriers and field devices. Isolators with test pulse immunity can distinguish between genuine input signals and diagnostic pulses, ignoring the latter to prevent false triggering or signal distortion.

Without this capability, test pulses could cause erratic behavior or disrupt signal integrity, compromising both safety and process reliability. Test pulse immunity ensures that isolators maintain stable communication with field devices even in electronic systems with frequent diagnostics, ensuring uninterrupted signal transmission and safe operation.

3. What Is Automatic Proof Testing of Safety Relays and How Is It Performed?

Safety relays play a key role in signal transmission between the control system and field devices, ensuring that field devices switch on or off safely in the event of a fault to prevent damage to the plant, personnel, and the environment. They must transmit a switching operation with absolute reliability as soon as the safety function is requested. The automatic proof testing for safety relays is an important diagnostic function to ensure the reliability of safety-related control systems in industrial environments.

The proof test intervals of safety relays from Pepperl+Fuchs are usually significantly longer than the maintenance intervals of a system, so that no additional testing effort is required for the modules. These long test intervals are achieved by a 1oo3 (one-out-of-three) architecture with the double redundant design of the switching contacts. Three contacts are arranged in series for DTS (de-energized-to-safe) applications and two groups of three parallel contacts each for ETS (energized-to-safe) signal circuits. Even if up to two contacts in a group fail, the safety function is still guaranteed. The modules’ integrated diagnostic function moves the three contacts one after the other with a time delay for each switching operation. In ETS applications, all three relays of the two contact groups close once after three consecutive switching events. During the delay time, the device checks whether this contact closes the circuit. Faulty contacts are detected.

The diagnosis of the DTS device takes place during the reclosing process: First, two relay contacts are closed simultaneously, then the third contact is also closed with a time delay. No current must flow before the third contact closes, otherwise this relay is defective as it no longer disconnects the circuit. A different relay is tested with each switching cycle.

The safety relay is fully tested after three switching cycles. This drastically reduces the time and effort required for proof tests.

Watch the video and learn more about intelligent safety relays with diagnostics and line fault transparency:

4. Why Are the Diagnostic Functions and Compatibility of Isolators Important for Distributed Control System (DCS) Integration and Beyond?

Numerous users benefit from the diagnostic functions and compatibility of Pepperl+Fuchs isolators, including control engineers, maintenance teams, and system integrators. The diagnostic functions enable real-time monitoring of field circuits, making it easier to detect and locate faults such as wire breaks, short circuits, or degraded signal quality. With early warnings and detailed status information, diagnostic isolators help reduce unplanned downtime, improve maintenance planning, and enable predictive maintenance.

Compatibility with distributed control systems (DCS) enables consistent data exchange and central access to diagnostic information. DCS integration simplifies configuration, enables better system monitoring, and supports compliance with safety and performance standards. In addition, the diagnostic functions contribute to higher system availability and efficiency in the process industry, where reliability and safety are of critical importance.

5. How Does HART Transparency of Isolators Create Additional Value?

Many isolators from Pepperl+Fuchs offer full HART transparency alongside the diagnostic functions mentioned above. The HART-enabled isolated barriers of the K-System and H-System enable the exchange of measured values, diagnostic information, and configuration data with the field device via the HART protocol. This means that the HART signal can pass through the isolator module unimpeded, enabling communication with HART-enabled field devices from both the field level and the control system side. The HART signals can be transmitted simultaneously with the analog 4–20 mA signal over the same line, which opens up higher data density and extended diagnostic options. Users benefit from easier maintenance, faster troubleshooting, and full access to extended device data across the entire control loop.

Subscribe to our newsletter and receive regular news and interesting facts from the world of automation.