Energy Efficiency and Cost Savings: PS1000 Power Supplies in Industrial Applications

Content of This Article

Energy Efficiency and Cost Savings: PS1000 Power Supplies in Industrial Applications

Sustainable, energy-efficient production processes are becoming increasingly important in modern industrial applications worldwide, not least due to the climate targets set by the EU Commission for 2030. Optimizing power consumption plays a key role here: energy consumption must be minimized and the carbon footprint reduced.

Consequently, even in the selection of suppliers, systems, parts, and components, a growing number of users are becoming increasingly conscious of a responsible use with resources. Innovations in the field of energy-efficient technologies such as the PS1000 series power supplies from Pepperl+Fuchs can make a contribution here: they offer energy-efficient and cost-saving product features. This blog article addresses the importance of sustainability for power supplies in industrial applications, focusing on the transformative role of energy efficiency.

Efficiency Affects Product Lifetime and Size

The efficiency of a power supply is one of the most important characteristics when selecting a product. Hardly any other technical value is so representative of the quality and excellence of the development work. The efficiency describes what proportion of the input power reaches the output of the power supply. Due to losses, this value is always less than 100 %.

Due to constant progress in the field of power electronics, almost all modern power supplies on the market achieve an efficiency of over 90 %. This means that 90 % of the energy used is utilized, while the remaining 10 % is lost in the form of heat. This power dissipation is generally avoided, as increased heat dissipation has many consequences. It leads to a higher component and device temperature, which in turn noticeably reduces the expected lifetime of the power supply. An temperature increase of 10 K leads to a halving of the remaining lifetime. This shows the immense importance of efficiency.

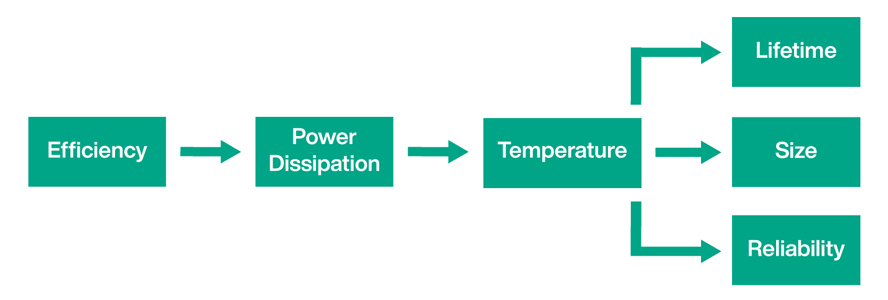

However, a high degree of efficiency not only leads to lower power dissipation, lower temperatures in the device and therefore a longer lifetime, but also directly influences the size and reliability of a power supply. The lower the temperatures in the power supply, the smaller the device can be built. This also increases reliability.

Chart 1: The impact of the efficiency of a power supply and its direct influence on lifetime, size, and reliabilty.

Device Comparison: Small Deviations, Big Disadvantages

In terms of efficiency, the power supply units in the premium segment are obviously very close to each other, as their efficiency values differ only minimally. However, as the following sample calculation shows, supposedly small deviations can have a major impact.

The Pepperl+Fuchs PS1000-A6-24.10 power supply has an efficiency of 95.2 % at 230 V. For comparison, let’s take a device from the same segment and the same power class, which achieves 93.4%. Nominally, there is only a difference of 1.8 % between the two values—with very significant consequences, as the direct comparison shows.

The PS1000-A6-24.10 power supply from Pepperl+Fuchs

| PS1000-A6-24.10

Power Supply |

Comparison Device

240 W |

||

|---|---|---|---|

| Efficiency | 95.2 % | 93.4 % | -1.8 % efficiency |

| Power dissipation | 12.1 W | 17 W | +40 % more power dissipation

= 40 % more heat in the appliance |

| Construction width | 39 mm | 50 mm | |

| Volume | 0.57 Liter | 0.81 Liter | |

| Weight | 600 g | 894 g |

Table 1: Comparison of the Pepperl+Fuchs PS1000-A6-24.10 power supply to a comparable 240 W power supply device.

In this device comparison, a difference in efficiency of 1.8 % already leads to +40 % more power dissipation and therefore heat in the competitor device. This also results in a significantly wider housing, more volume, and a higher weight. A shorter lifetime of the comparable device is to be expected.

Effects of Efficiency on Energy Consumption and Costs in System Operation

The factors mentioned above play a major role in energy efficiency in production (and also in sustainability, in a broader sense). A higher power dissipation means that more power must be consumed with the less efficient power supply in order to achieve the same output power. If you now consider the entire lifetime of a system, this leads to drastically higher energy costs compared to the PS1000 component. The following calculation example, which is based on realistic assumptions, illustrates this:

| Assumptions | |

|---|---|

| Running time of a power supply per day | 24 hours/day |

| Running time of a power supply per year | 360 days/year |

| Lifetime of the system/power supply | 15 years |

| Number of power supplies | 1 |

| Electricity price industry Germany 2023 [1] | 0.2650 €/kWh |

| CO2-emission factor electricity mix Germany 2023 [2] | 380 g/kWh |

Table 2: Calculation based on realistic assumptions of power supply usage.

[1] Source: BDEW German Association of Energy and Water Industries, electricity price analysis June 2023

[2] Source: Federal Environment Agency, Development of specific emissions of the German electricity mix 1990-2023

The assumptions made describe a standard application in Germany. The example system runs, as usual, 24 hours a day, 360 days a year. The remaining days are reserved for maintenance work. Typically, the system runs for 15 years with one power supply until a planned replacement is carried out.

Based on the assumptions of the previous device comparison, the following effects result for a single power supply unit based on the efficiency difference of 1.8 %:

- The difference in efficiency results in an increased power loss of 4.9 W.

- Over the exemplary service life of the power supply in the system of 15 years, an additional consumption of 635 kWh of electricity is calculated.

- This energy has been lost entirely in heat and paid for unnecessarily. At the electricity price mentioned above, that is €168 of wasted money for one power supply.

- Extrapolated to an entire factory with hundreds of power supplies, this difference can reach a critical amount or provide a simple approach for optimization.

High Efficiency, Lower CO2 Footprint

Based on the regional electricity mix, a CO2 emission factor is calculated annually. In Germany, this was 380 g/kWh in 2023, taking into account the upstream chains. The additional wasted electricity of 635 kWh of the comparison device results in additional CO2 emissions of around 0.25 tons of CO2 per year per power supply unit. Extrapolated to an entire plant or factory, this reaches tangible proportions for plant operators.

The carbon footprint is therefore significantly influenced by the choice of power supply unit. The highly efficient PS1000 power supplies from Pepperl+Fuchs make a positive contribution to a company’s carbon footprint.

The efficient and sustainable PS1000 series power supplies from Pepperl+Fuchs.

Subscribe to our newsletter and receive regular news and interesting facts from the world of automation.