Photoelectric Sensors in Conveyor Technology: Four Sensor Solutions for Presence and Object Detection

Content of This Article

Photoelectric Sensors in Conveyor Technology: Four Sensor Solutions for Presence and Object Detection

Every day, millions of goods are packaged and shipped worldwide. To ensure that they reach their destination quickly and safely, intralogistics processes are being continuously optimized and automated. Photoelectric sensors are often used in conveyor technology to reliably detect packages, pallets, or other goods. These sensors not only have to perform demanding detection tasks, such as detecting shiny packaging films or polybags, but also have to meet special requirements when mounted on conveyor systems. For example, the sensors must be quick and easy to install, even in confined spaces. At the same time, durable mounting options and high mechanical stability are required to withstand vibrations during operation. Pepperl+Fuchs offers a wide variety of photoelectric sensors that are ideal for conveyor applications due to their well-engineered mounting brackets. In this blog article, we will highlight four sensor solutions for reliable presence monitoring and object detection.

Smooth Flow of Goods: Cylindrical Sensors from the M18 Series

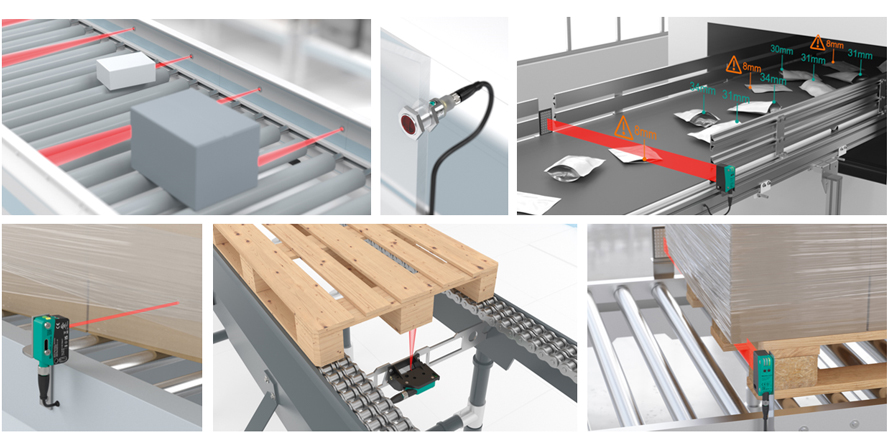

The cylindrical photoelectric sensors of the M18 series are versatile and ideal for presence and object detection on conveyor systems. On roller conveyors, for example, they provide the information needed to control start, stop, or ejection. They are available as thru-beam sensors, retroreflective sensors with transparency detection, or as retroreflective sensors with and without background suppression in virtually all standard applications.

The cylindrical photoelectric sensors of the M18 series are ideally suited for presence and object detection on conveyor systems.

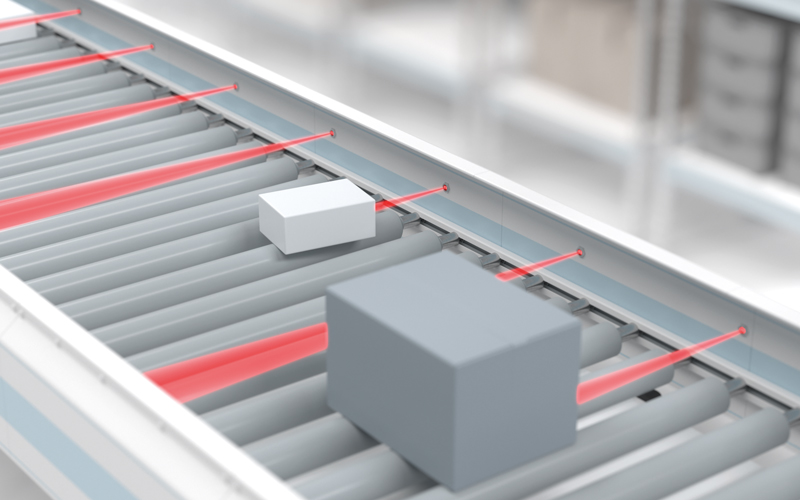

With their industrial-grade metal housing and threaded metal housings, the cylindrical sensors offer particularly high resistance to mechanical stress—ideal for use in conveyor technology. In addition to devices with a length of 60 mm, shorter versions with a length of 40 mm are also available for space-saving installation. The 90° side-looker version allows installation from below and sensing around corners. And due to their user-friendly setup, the sensors can be easily integrated into the system and put into operation.

The cylindrical M18 photoelectric sensors offer high mechanical stability due to their metal housings and integrated all-metal bushings.

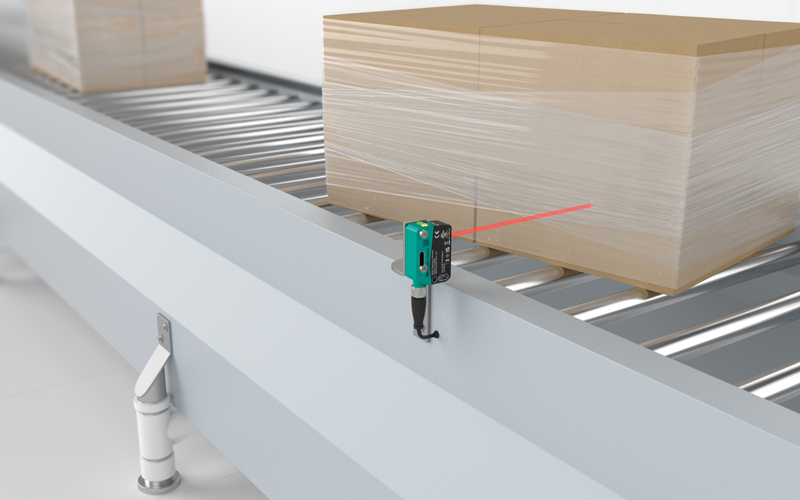

Reliable Detection and Height Measurement of Non-Uniform Packaging: R305 Retroreflective Area Sensor

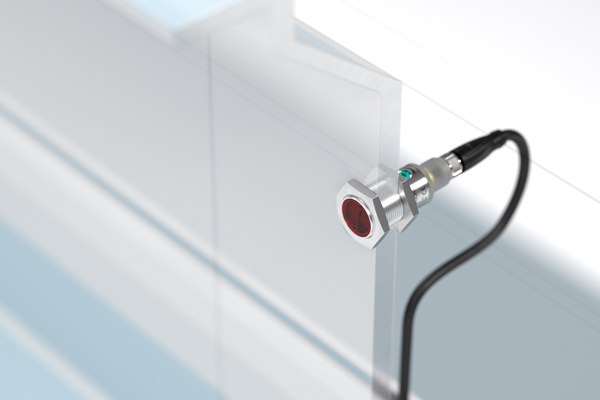

Whether small packets and pouches, polybags, or pallets—the R305 retroreflective area sensor is used where standard retroreflective sensors reach their limits. With its 60-mm-wide light band, it can easily detect non-uniform packaging with irregular contours as a single object without triggering unwanted multiple switching. The R305 retroreflective area sensor detects even narrow edges precisely and reliably. In addition to pure object detection, the devices also feature integrated height measurement. This data can serve as a basis for further sorting and classification applications.

The integrated IO-Link interface enables continuous data transmission as well as easy parameterization and adjustment of range, resolution, and contrast level, therefore ensuring optimal processes. The transmission of measurement and status data also enables predictive maintenance and reduced downtime.

The R305 retroreflective area sensor's wide light band reliably detects narrow objects such as polybags, avoiding multiple switching. The integrated height measurement enables further sorting and classification of packages.

The retroreflective area sensor can be easily attached to conveyor systems with the supplied mounting bracket (OMH-R305-01). For very confined spaces, a compact side-looker version with mounting bracket and deviation mirror is available, allowing the sensor to be conveniently mounted at a 90° offset. The “Easy Alignment Mode” ensures intuitive and quick installation: a yellow LED indicates the correct alignment of the sensor with the reflector, without any time-consuming adjustments.

The R305 can be easily mounted on conveyor systems with the supplied mounting brackets.

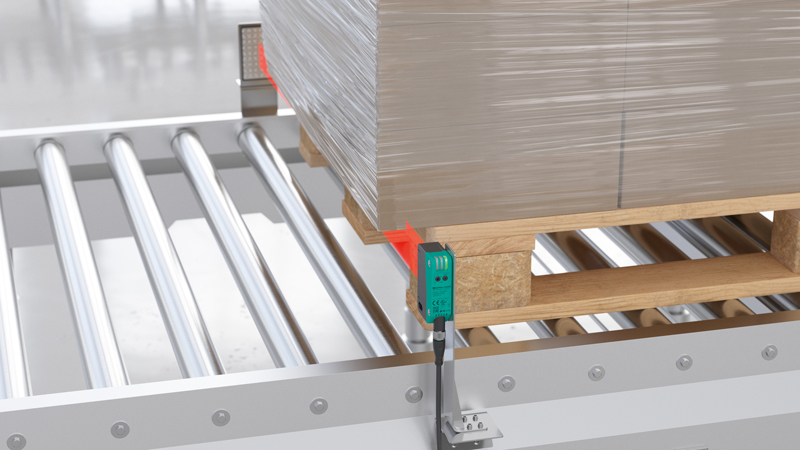

Reliable Detection of Shrink-Wrapped Pallets: Cubic Sensors from the R202 Series

The cubic sensors from the R202 series are specially designed for the requirements of conveyor technology. The version for transparency detection has a particularly high detection capability for recognizing shiny objects, such as shrink-wrapped pallets. However, the R202 series also includes thru-beam sensors, retroreflective sensors, and diffuse mode sensors for other detection tasks.

A combination of standard holes and slotted holes enables horizontal and vertical mounting of the compact sensors. Compatible accessories such as the OMH-R202* mounting bracket or standard mounting brackets ensure easy installation. In addition, the R202 series sensors feature integrated full metal bushings. This increases mechanical stability, allowing for higher tightening torques. This supports long-term stable use on conveyor systems.

The R202 series photoelectric sensors are ideally suited for material handling applications. The sensors can be mounted horizontally or vertically.

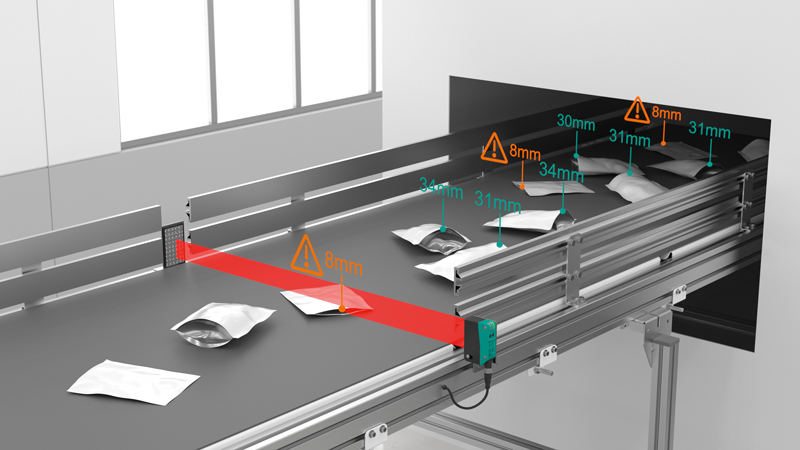

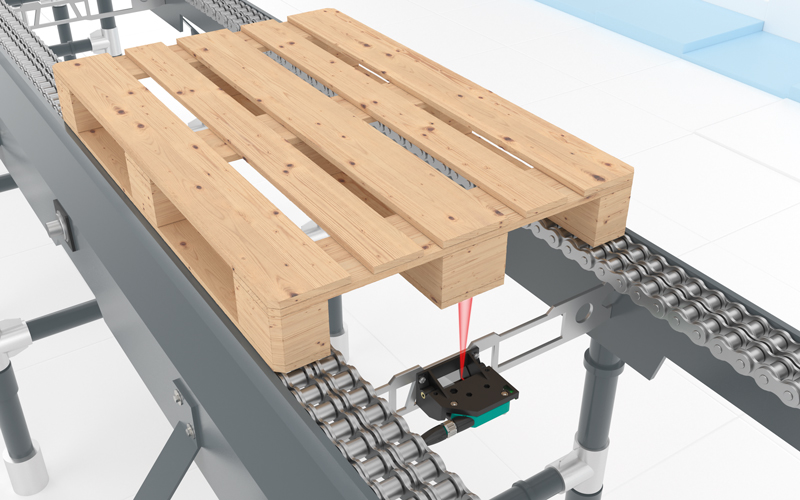

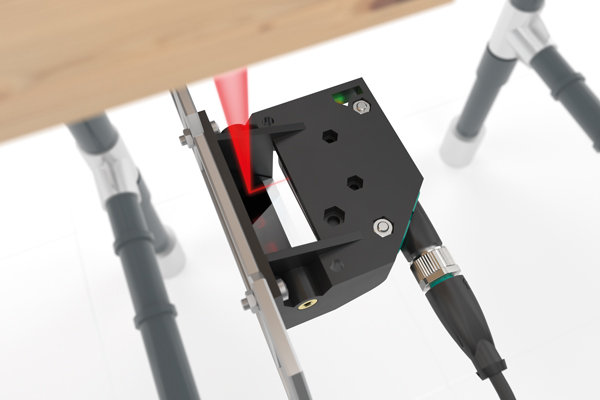

Application-Specific Sensor Solution for Pallet Detection: The Pallet Detector

Pepperl+Fuchs offers the Pallet Detector, a sensor solution specially developed to reliably detect pallets on conveyor lines. A R201 series diffuse mode sensor, used with a separate sensor mount with integrated mirror, is used to detect pallets. This has a 45° angle so that dirt and dust slide off more easily. For convenient installation, the sensor and mount can be delivered pre-assembled.

If special plastic pallets with many recesses need to be detected, the photoelectric sensor can be easily replaced with an F77 series ultrasonic sensor.

The Pallet Detector was specially developed for the reliable detection of pallets on conveyor lines.

The compact design allows for space-saving installation. Unlike conventional systems, the pallet detector is not mounted on the side, but inside the conveyor system. The solution is attached to the crossbar within the conveyor line. This eliminates the need for protruding round bars, which increases work safety in the system. Installation inside the conveyor line also reduces logistics costs, as the individual line sections are easier to stack, pack, and transport.

An application-specific sensor bracket allows easy and space-saving installation within the conveyor line.

More Information

You may also be interested in

- Retroreflective Area Sensors—Where Standard Retroreflective Sensors Reach Their Limits

- Intelligent Valve Control with IO-Link in Conveyor Technology

- Vision Sensors—Three Examples for Industrial Vision in Material Handling (Part 2)

- Vision Sensors—Use Cases for Industrial Vision in Material Handling (Part 3)

Subscribe to our newsletter and receive regular news and interesting facts from the world of automation.