Safely Protect Signal Lines from Surges with the M-LB-4000 Surge Protector

Content of This Article

Safely Protect Signal Lines from Surges with the M-LB-4000 Surge Protector

Lightning and surge damage are among the most common causes of damage to electronics. The increasing use of electronic devices alone, whether in industry, office buildings, or smart home applications, means that such events cause major material and financial damage. In process plants such as refineries or the water and wastewater industry, surges can have even more devastating consequences if a surge event causes damage or unintended functionality of machines and systems.

Find out more about the important topic of surge protection and how you can protect your system and signal lines safely and easily.

Why Surge Protection Is Essential

Overvoltages can be the result of lightning strikes, but also switching operations, electrostatic discharge, faults in the supply, or the installation of power and signal cables in the same cable tray or conduit. All voltages that exceed a permissible limit value, even if only briefly, are overvoltage events. Current and voltage peaks are one of the most common causes of damage to electronics, as overvoltages usually hit sensitive system parts such as electronic circuits on printed circuit boards, motherboards, and network interface controllers first. In process plants such as those in the chemical, petrochemical, and wastewater industries, these can have serious consequences. If the electronics of machines and system components are destroyed, this can lead to fatal malfunctions or the failure of entire automation systems. Surges therefore not only pose a potential risk to plant areas, but also to people and the environment. For this reason, you should always protect process technology systems and vulnerable components from such events with appropriate surge protection devices.

How Surge Protection Works

Surge protectors limit induced transients on signal lines caused by lightning or switching operations. The devices reduce voltage peaks to a level that is safe for the end device, therefore preventing devastating damage and consequential costs caused by overvoltage events.

Two-Part Surge Protection of the M-LB-4000 Series

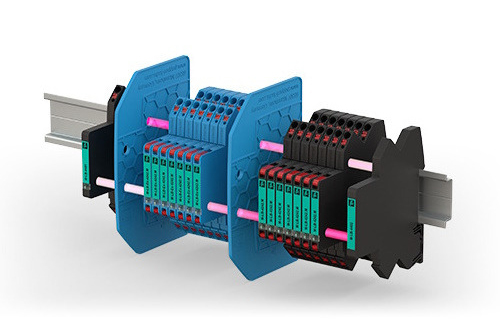

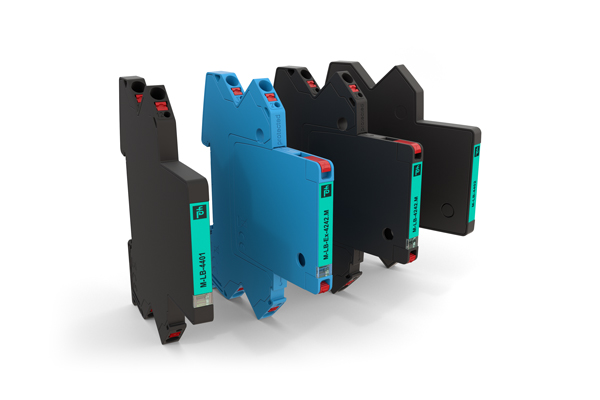

Pepperl+Fuchs offers a wide range of systems for safe surge protection in your installations. The M-LB-4000 surge protection system for signal lines up to SIL 3 in accordance with IEC/EN 61508 is a modular two-part surge protection device. A fault status monitoring module can be added to indicate when a surge module needs replaced. The 2-wire surge protection modules contain all the protective components, and do not need to be rewired when replacing them. The two components of the fault status module monitor the status of up to 50 surge protection barriers.

The M-LB-4400 fault status module consists of two parts: an optical transmitter/receiver and an optical deflection unit. If a fault occurs in a surge protection barrier, the signal is interrupted and the fault is identified. The fault status module has an LED status indicator and therefore enables visual inspection and meets the normative requirements for regular testing. The block of modules in which the fault has occurred can be identified via the status signal output. A relay contact transmits the status information to the control room, increasing plant availability. Defective modules can be replaced immediately.

With their small width of 6 mm, the devices also save space in the switch cabinet. When retrofitting, existing standard knife disconnect terminals can be replaced without taking up any space. The modules are simply plugged onto the DIN mounting rail without the use of tools.

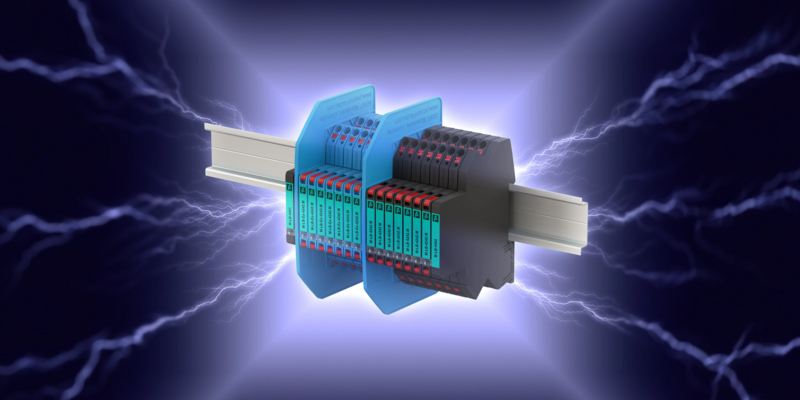

M-LB-4000 surge protection system: Two components of the fault status module (both external) monitor the status of the protection modules, in this case two blocks for intrinsically safe circuits and signals from/to the safe area.

Module Change Without Signal Interruption

The protection modules of the M-LB-4000 surge protection system from Pepperl+Fuchs can be replaced without tools during operation without interrupting signal transmission. When a protection module is removed, the affected signal circuit remains connected via the base module mounted on the DIN mounting rail without interrupting the signal or impairing system operation.

Loop Disconnect Function for Easy Maintenance

If the protection module is plugged into the base module rotated by 180 degrees, the signal circuit is interrupted by the integrated disconnect function (loop disconnect). This practical functionality enables maintenance work to be carried out in a de-energized state, simplifies loop checks, and enables insulation tests during commissioning or recurring tests.

Modular surge protection of the M-LB-4000 series from Pepperl+Fuchs: two-part fault status module (outside) and protection modules (center).

More Information

Subscribe to our newsletter and receive regular news and interesting facts from the world of automation.