Retroreflective Area Sensors—Where Standard Retroreflective Sensors Reach Their Limits

Content of This Article

- Reliable Detection of Small and Irregularly Shaped Objects

- Standard Retroreflective Sensors: Point-Shaped Detection with Limitations

- R305 Retroreflective Area Sensors: Wide Light Band for Comprehensive Detection

- Detection of Irregularly Shaped Polybags on Conveyor Belts

- Detection of Pallets on Conveyor Belts

- More Information

Retroreflective Area Sensors—Where Standard Retroreflective Sensors Reach Their Limits

Reliable Detection of Small and Irregularly Shaped Objects

In logistics, material handling, or the packaging industry, reliable object detection is crucial to ensure efficient processes. Traditionally, retroreflective sensors are used for this purpose. As these operate with a single-point light beam, conventional retroreflective sensors reach their limits in certain applications. The R305 retroreflective area sensor from Pepperl+Fuchs, on the other hand, uses a wide light band to reliably detect even irregular shaped and very narrow objects.

In this blog article, you will learn about how retroreflective sensors function and when a retroreflective area sensor is the best fit for your application.

Standard Retroreflective Sensors: Point-Shaped Detection with Limitations

Retroreflective sensors consist of an emitter and a receiver aligned in the same housing. The emitter sends out light, which is then reflected back by an opposing reflector and detected by the receiver. When an object interrupts this light beam, the sensor recognizes it as a signal. This technology is effective for detecting objects that have clear contours and well-defined positions. However, small, narrow, or irregularly shaped objects may not consistently interrupt the focused light beam and, as a result, can easily be overlooked.

With a point light beam, the object may not be detected at all or only after a noticeable delay. Irregular contours could trigger multiple switching.

R305 Retroreflective Area Sensors: Wide Light Band for Comprehensive Detection

The R305 retroreflective area sensor operates with a 60 mm wide light band made up of five individual beams, each measuring 12 mm. This wide detection field ensures reliable detection of objects, regardless of their shape, size, or position. Even small or irregularly shaped objects are consistently recognized, as they interrupt at least one of the light beams. Additionally, each beam can be switched off individually, allowing users to exclude interfering objects in the detection area or to adjust the overall height of the light band to a narrow opening.

The R305 retroreflective area sensor's wide light band reliably detects narrow object edges and avoids multiple switching.

Detection of Irregularly Shaped Polybags on Conveyor Belts

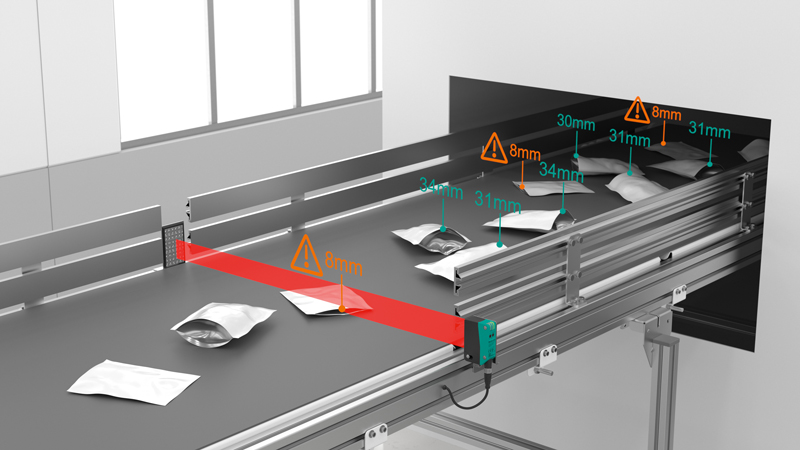

In modern logistics centers and packaging lines, products such as textiles, electronics, or accessories are often packaged in polybags. These flexible plastic bags have irregular contours that conventional retroreflective sensors struggle to detect reliably due to their single-point light beam. However, the R305 retroreflective area sensor ensures that the pouch remains in the light band as it passes by, triggering a single object detection circuit.

The leading edge of the bag that reaches the detection zone first can be very small. In High Resolution Mode, the R305 retroreflective area sensor detects objects as small as 2 mm in height, ensuring reliable and comprehensive detection of polybags. This level of precision is crucial for processes such as sorting, labeling, and quality control.

The R305 retroreflective area sensor reliably detects polybags of different heights and contours due to its wide detection field.

Detection of Pallets on Conveyor Belts

When detecting pallets, traditional retroreflective sensors often trigger intermittently due to the open areas between the pallet feet. As a result, a typical pallet may be detected three times while passing by, with the sensor inaccurately reporting “no object” twice in between detections.

The R305 retroreflective sensor provides a more reliable solution. Its wide light band allows it to continuously detect the pallet as it moves, recognizing it as a single object. The leading edge is detected, even if the load extends beyond the edge of the pallet. Additionally, the R305 can simultaneously monitor both the pallet base and its load from a distance of up to 4 meters.

Due to its wide light band, the R305 can simultaneously monitor both the pallet base and its load, detecting it as a single object.

Subscribe to our newsletter and receive regular news and interesting facts from the world of automation.