Reliable Object and Transparency Detection—Photoelectric Sensors in Packaging Technology

Content of This Article

Reliable Object and Transparency Detection—Photoelectric Sensors in Packaging Technology

Packaging technology is constantly changing, with technological trends contributing significantly to increased efficiency in production. Modern, fully automated packaging and filling systems in the food and beverage industry, pharmaceuticals, and cosmetics sectors rely on smart sensor technology, transparent data transmission, and integration into higher-level control systems to ensure smooth production processes. Modular system concepts that enable flexible adaptation to changing production requirements are becoming increasingly important.

The use of innovative technologies and smart sensor technology enables fully automated processes and continuous monitoring in real time. Find out how photoelectric sensors ensure reliable processes in packaging technology and master difficult challenges such as the detection of transparent film, glass, and PET bottles.

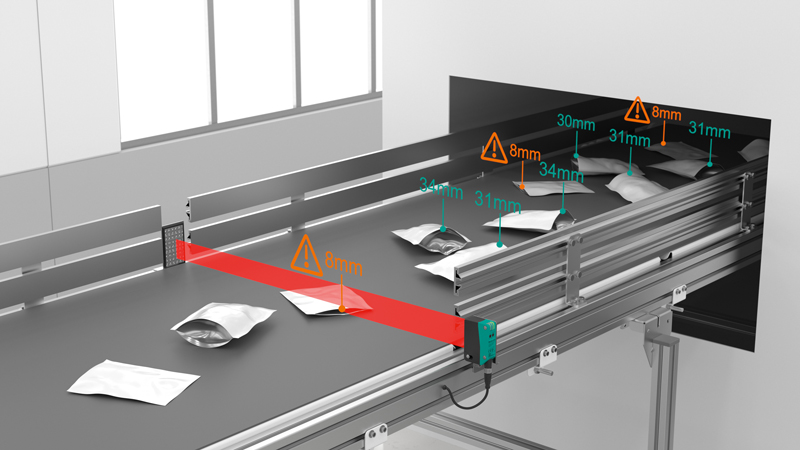

Reliable Detection, Presence Checking, and Quality Control

Photoelectric sensors are key components in modern packaging and filling systems, as they enable precise and non-contact detection of objects. Thanks to various operating principles, such as retroreflective sensors with polarization filter, diffuse mode sensors with background or foreground suppression, and distance sensors, a wide range of requirements can be met. Their high precision and reliability in detection, presence, and quality control make them versatile. Photoelectric sensors are insensitive to interference such as dust, moisture, or ambient light, ensuring reliable detection in demanding production environments. With their compact designs and high resistance to interference, they ensure smooth operations in modern packaging and filling systems.

Typical Applications of Photoelectric Sensors in Packaging Technology

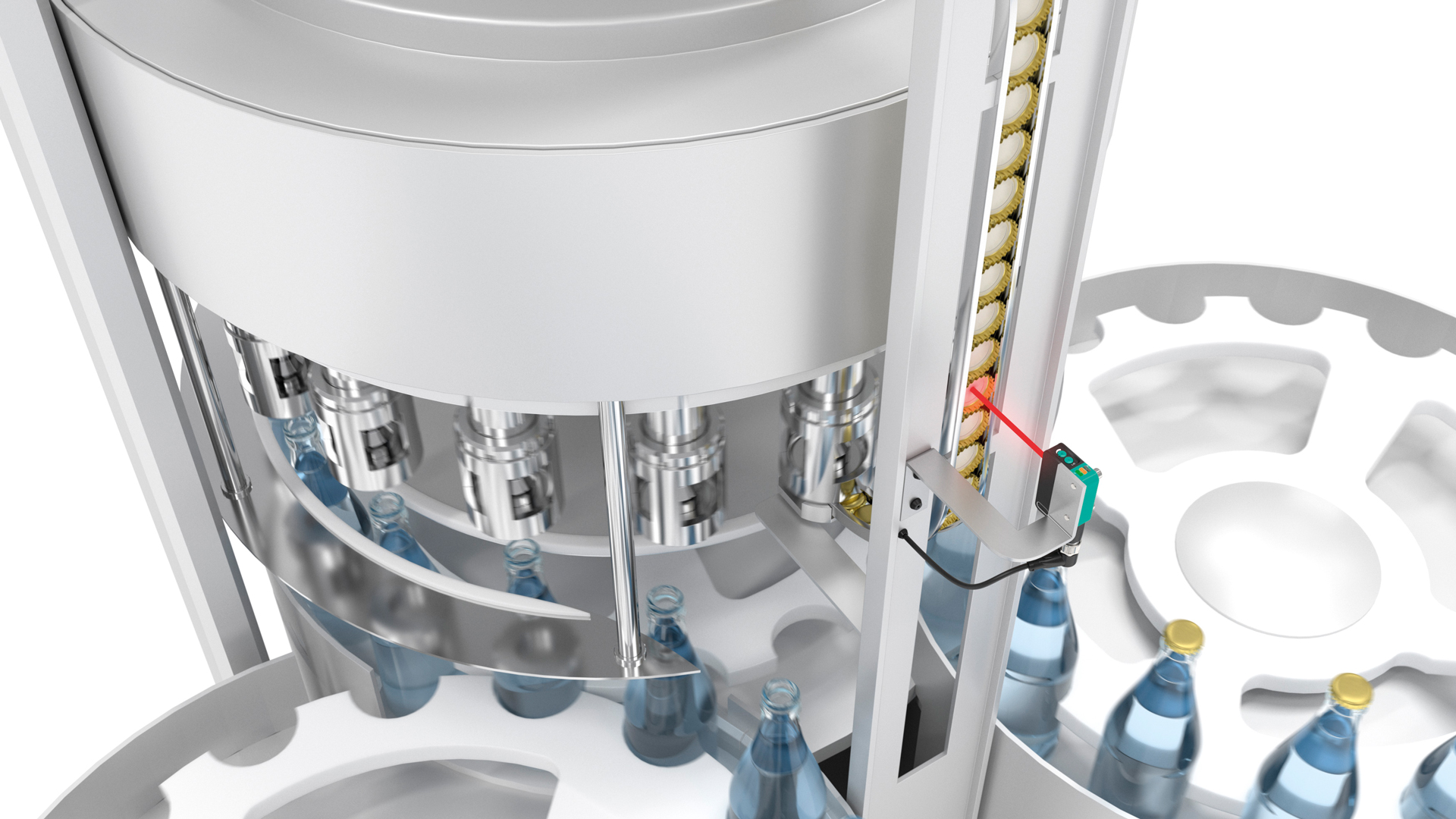

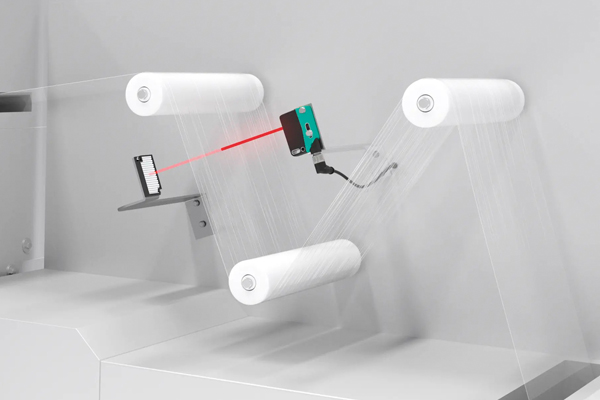

Detection of Clear Glass, PET Bottles, and Transparent Films

Detecting clear glass, PET bottles, or transparent film can be tricky: depolarization, reflections, and unwanted focus effects may occur to varying degrees, either canceling each other out or amplifying one another. The surface curvature of bottles causes focus effects that can increase the received signal. All these effects can lead to false switching, which must be avoided under high-speed operation. The dominant effect, depolarization, can be applied using a reflector with a circular polarization filter to increase detection reliability.

The Pepperl+Fuchs R10x and R20x series retroreflective sensors are ideal for these tasks and ensure error-free detection of glass, PET bottles, and transparent films. By using a reflector with a polarization filter, they can reliably detect shiny, reflective, and transparent objects. They ensure trouble-free production processes and help reduce downtime and increase plant availability.

Common Applications of Retroreflective Sensors for Clear Glass and Transparency Detection

How Can Transparent Objects Be Reliably Detected and False Switching Avoided?

Retroreflective sensors consist of a transmitter and receiver unit in a housing and an associated reflector. The light beam emitted by the optical sensor is reflected back to the transmitter/receiver unit by the reflector. If an object interrupts the light beam, a switching function is triggered. However, shiny, reflective, or transparent objects can cause false switching due to depolarization or unwanted reflections. A reflector with a polarization filter is used for this purpose. The polarization filter additionally attenuates the light emitted by the transmitter. As a result, only the reflected light beams from the triple reflector reach the transmitter/receiver unit of the retroreflective sensor, as the reflector changes the polarization plane of the light so that it can pass unhindered through the polarizing filter in front of the receiver. Other reflections and mirroring, such as from glass bottles or foil, do not affect the switching accuracy of the sensors. Retroreflective sensors for clear glass detection recognize even the smallest differences in contrast and adjust the transmitter light intensity and receiver gain in case of contamination. This results in increased switching sensitivity with only slight absorption by the glass.

The compact OBG5000-R10x series of retroreflective sensors from Pepperl+Fuchs are specially designed for detecting transparent objects such as clear glass, PET, and transparent films. What makes them special is that they work with a circularly polarized LED light beam, whereas standard retroreflective sensors emit a linearly polarized light beam. The main advantage of circularly polarized light is that significantly more of the reflected light reaches the receiving unit when used with a reflector with a circular polarization filter (e.g., REF-H32G-2 or REF-ORR50G-2). This further improves detection reliability through a higher operating reserve. False switching is reliably avoided.

R100 retroreflective sensor enables reliable detection of transparent materials such as clear glass, PET bottles and films.

Briefly Explained: Advantages of a Reflector with a Circular Polarization Filter for Detecting Transparent Objects

When using a standard reflector without a polarization filter, a transparent film, glass, or PET bottle would only attenuate the light beam emitted by the transmitter on its way to the reflector and back by 5–10 %, with a slight rotation of the polarization. Using a reflector with a polarization filter reduces the signal by up to 90%, depending on the depolarization effect. Depolarization is used to increase detection reliability and make the transmitter/receiver unit significantly less sensitive to external influences.

Retroreflective sensors that emit a circularly polarized light beam, in conjunction with a reflector with a circular polarization filter, further increase detection reliability, as significantly more light reaches the receiver. This enables a higher operating reserve in the application and therefore improved operational reliability. Reflectors with circular polarization filter do not cause any losses in the optical system, and they have the same detection range as standard reflectors and those with linear polarization filter. In addition, there is no need to consider a specific mounting direction, as is the case with reflectors with linear polarization filters.

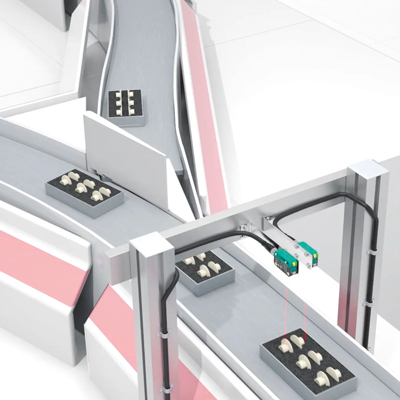

Easy System Integration

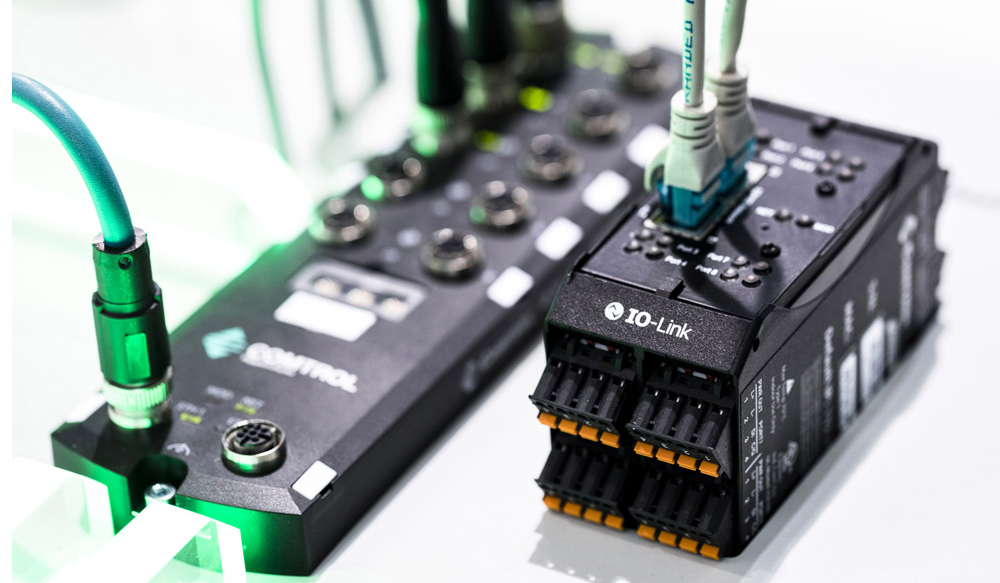

Modern photoelectric sensors feature an IO-Link interface that enables continuous communication with higher-level control systems and provides detailed process data. IO-Link supports flexible adjustment of parameters, processing diagnostic data, optimizing production based on data, and predictive maintenance of devices. Especially in fast, fully automated production processes, photoelectric sensors with IO-Link facilitate continuous monitoring and provide relevant data in real time, significantly reducing production waste and making more efficient use of resources such as raw materials and packaging materials.

Multiprotocol-capable IO-Link masters from the Pepperl+Fuchs ICE2 and ICE3 series ensure consistent communication and easy integration of IO-Link devices into higher-level systems. They provide continuous status monitoring, contamination control for optical sensors, and easy parameterization when replacing devices, changing production batches, or expanding systems.

The multiprotocol-capable IO-Link Masters of the ICE2 and ICE3 series from Pepperl+Fuchs enable easy and transparent system integration of IO-Link devices.

More Information

- Sensor solutions for the packaging industry

- Photoelectric sensors R10x and R20x series with IO-Link

- Retroreflective sensors with polarization filter for detecting clear glass, PET, and transparent films

- Retroreflective Area Sensors—Where Standard Retroreflective Sensors Reach Their Limits

- IO-Link Infrastructure: Taking Full Advantage of IO-Link

- IO-Link Masters: Infrastructure for cloud-based IoT applications

Subscribe to our newsletter and receive regular news and interesting facts from the world of automation.