Power Consumption and Power Dissipation in Electronic Systems—Efficient Isolated Barriers and Power Supplies

Content of This Article

- How Do Power Consumption and Power Dissipation Affect Energy Efficiency?

- What Are the Implications of Using Devices with Increased Power Consumption and Higher Power Dissipation?

- Low Power Consumption, Low Power Dissipation, Maximum Efficiency: Isolated Barriers and Power Supplies from Pepperl+Fuchs

- More Information

Power Consumption and Power Dissipation in Electronic Systems—Efficient Isolated Barriers and Power Supplies

Power consumption and power dissipation are two crucial factors in the operation of electronic systems. The efficiency of electronic components has a direct impact on performance, reliability, heat generation, and energy costs. Understanding how components consume and dissipate energy is important for increasing the efficiency of electronic systems and meeting increasingly stringent energy efficiency requirements.

In this blog article, learn how power consumption and power dissipation affect the energy efficiency of electronic systems, and how isolated barriers and power supplies from Pepperl+Fuchs contribute to improved efficiency and higher plant availability.

How Do Power Consumption and Power Dissipation Affect Energy Efficiency?

Power consumption refers to the total energy consumed by a device or system during operation, including all necessary DCS-side currents, such as those for field devices and control systems. This parameter is critical for determining the appropriate sizing and capacity of power supplies, which ensure stable and efficient system operation. Moreover, power consumption directly impacts operational energy costs throughout the system’s life cycle, making it a key factor in both economic and environmental considerations. The lower the power consumption of electronic devices, the higher their efficiency and the smaller the power supplies required. This has a positive effect on the energy efficiency of the entire electronic system.

Power dissipation, on the other hand, is the portion of consumed power that is converted into heat within electronic components. This heat generation raises device temperatures, which often requires additional cooling measures to maintain safe operating conditions. Excessive power dissipation can impair the reliability of the devices and shorten their service life. It also creates challenges in terms of heat management in the control cabinet, which limits design flexibility and requires, for example, spacing between modules. The power dissipation of electronic devices has a direct impact on the energy efficiency of the entire system.

These factors show why it is essential to carefully consider power consumption and power dissipation when selecting electronic components such as isolated barriers and power supplies. This is because not only the performance and service life of the devices depend on this, but also the plant availability and overall energy efficiency of the entire electronic system.

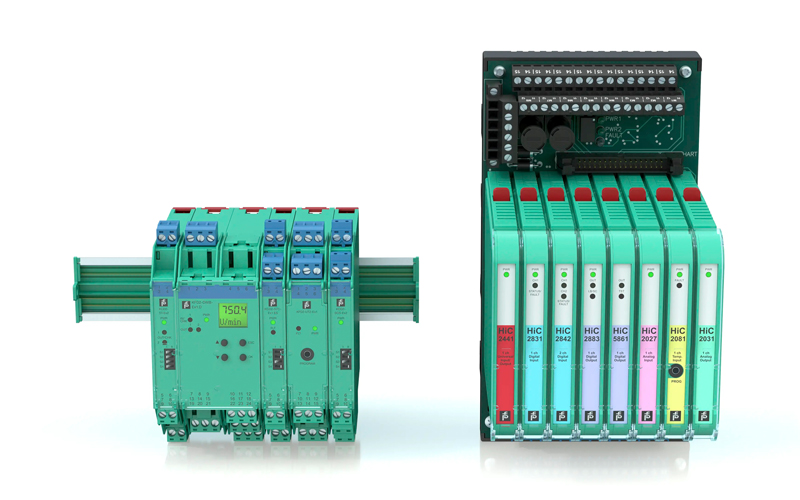

Efficient isolated barriers with low power dissipation: the K-System for DIN rail mounting (left) and the H-System for termination board mounting (right) from Pepperl+Fuchs

What Are the Implications of Using Devices with Increased Power Consumption and Higher Power Dissipation?

Power consumption and power dissipation are inseparably linked and directly affect the reliability and energy efficiency of an electronic system over time. When devices consume more power and emit large amounts of heat, the consequences go far beyond higher electricity costs:

- Increased power dissipation leads to higher temperatures in the control cabinet, which requires larger, more expensive cooling systems or can create hot spots that compromise component reliability.

- Increased device temperatures accelerate component aging, degrade insulation, and affect solder joints and semiconductors, shortening product life and increasing the risk of premature failure.

- Higher power consumption may require larger power supplies and more extensive cabling, increasing installation costs and reducing space in the control cabinet.

- To prevent overheating, channel density may need to be reduced, resulting in lost space in the control cabinet and increasing the system’s footprint.

Over time, this can compromise component reliability and lead to increased maintenance, unplanned downtime, and higher total operating costs—problems that can be avoided with efficient devices such as Pepperl+Fuchs isolated barriers and industrial power supplies, which are designed for low power consumption and low power dissipation.

A Comparison: Power Dissipation of Isolated Barriers

We compared the KCD2-VR4-Ex1 voltage repeater from Pepperl+Fuchs, a 1-channel isolated barrier for transmitting voltage signals from vibration measurements in explosion-hazardous areas, with two devices from the same segment and the same performance class.

KCD2-VR4-Ex1 voltage repeater from Pepperl+Fuchs with low power dissipation.

Table 1:

| Voltage repeater KCD2-VR4-Ex1 1-channel isolated barrier |

Comparison device 1 | Comparison device 2 | |

|---|---|---|---|

| Max. power dissipation | <0.9 W* | 1.4 W | 2.0 W |

| Corresponds to a 64.7% higher power dissipation | Corresponds to a 135.3% higher power dissipation | ||

| Width | 12.5 mm | 17.6 mm | 12.5 mm |

| Weight | Approx. 100 g | Approx. 150 g | Approx. 125 g |

* Used for calculations: 0.85 W

If we take a look at the maximum power dissipation of the three devices in Table 1, we can see how seemingly minor differences can make a significant impact:

Comparative device 1 has a power dissipation that is 64.7% higher than the voltage repeater from Pepperl+Fuchs. The higher power dissipation and associated heat emission result in a larger housing design and higher weight of the devices. This reduces the space available in the control cabinet and may require additional ventilation and cooling measures. In addition, higher power dissipation shortens the expected service life of the devices.

Comparative device 2 even has 135.3% higher power dissipation than the 1-channel isolated barrier from Pepperl+Fuchs, despite having the same width. This leads to higher device temperatures and, consequently, a shorter expected product life. In addition, the high power dissipation and heat generation require more ventilation and cooling measures in the control cabinet, while simultaneously reducing the channel and module packing density.

Assuming a control cabinet with eight rows of 60 modules, this means approximately 552 W more power dissipation compared to the voltage repeaters from Pepperl+Fuchs. Calculated over a year, this amounts to around 4,800 kWh, which corresponds to the average consumption of a 4-person household in a single-family home. Over a useful working period of 15 years, this amounts to 72,500 kWh. Calculated for an entire system, the higher power dissipation is clearly noticeable in both costs and carbon footprint.

A Comparison: Power Dissipation of Power Supplies

A further comparison of the efficiency and power dissipation of industrial power supplies in the premium segment shows that a difference in efficiency of just 1.8% in comparable devices results in 40% more power dissipation. An increase in temperature of just 10 Kelvin already halves the expected product life.

Low Power Consumption, Low Power Dissipation, Maximum Efficiency: Isolated Barriers and Power Supplies from Pepperl+Fuchs

Pepperl+Fuchs offers high-performance isolated barriers with some of the lowest power consumption and power dissipation in the industry. The advantages are evident throughout the entire installation: The efficient isolated barriers of the K-System and H-System from Pepperl+Fuchs require less power than comparable devices from other manufacturers. Their low energy consumption, low power dissipation, and optimized thermal design help maintain stable operating temperatures without oversized cooling solutions. They enable higher module packing density without compromising reliability. This not only reduces upfront infrastructure costs, but also extends the service life of the devices and increases the reliability of the entire system.

The lower power consumption of the components means that smaller power supplies can be used. Pepperl+Fuchs supports this with its PS1000 series industrial power supplies, which are both efficient and powerful for process industry applications. At the same time, smaller and more efficient devices also mean lower power dissipation and associated heat generation. This reduces the need for cabinet ventilation and cooling, which in turn enables higher channel density in the control cabinet. Overall, plant operators benefit from lower energy consumption throughout the system’s service life.

The low power consumption and particularly low power dissipation not only extend the service life of the devices, but also lead to measurable cost savings and lower total cost of ownership, making the H-System and K-System isolated barriers and PS1000 power supplies from Pepperl+Fuchs the ideal solution for signal transmission and power supply in the control cabinet.

The efficient K-System isolated barriers and PS1000 power supplies with low power dissipation allow a higher channel and module packing density in the control cabinet.

More Information

- Isolated barriers and signal conditioners of K-System

- Intrinsic safety barriers of the H-System

- PS1000 industrial power supplies

- KCD2-VR4-Ex1 voltage repeater for vibration measurements in hazardous areas

Subscribe to our newsletter and receive regular news and interesting facts from the world of automation.