Reliably Filling, Sealing, and Packaging: Applications of Photoelectric Sensors in Fully Automated Filling Systems

Content of This Article

- Trouble-Free Filling Process: Reliable Detection of Transparent Bottles

- Reliable Sealing: Automated Lid Feeding in High-speed Processes

- Reliable Film Tear Control: Error-Free Packaging with PET Film

- Future-Oriented Sensors for Packaging Technology: the R10x and R20x Series from Pepperl+Fuchs

- More Information

Reliably Filling, Sealing, and Packaging: Applications of Photoelectric Sensors in Fully Automated Filling Systems

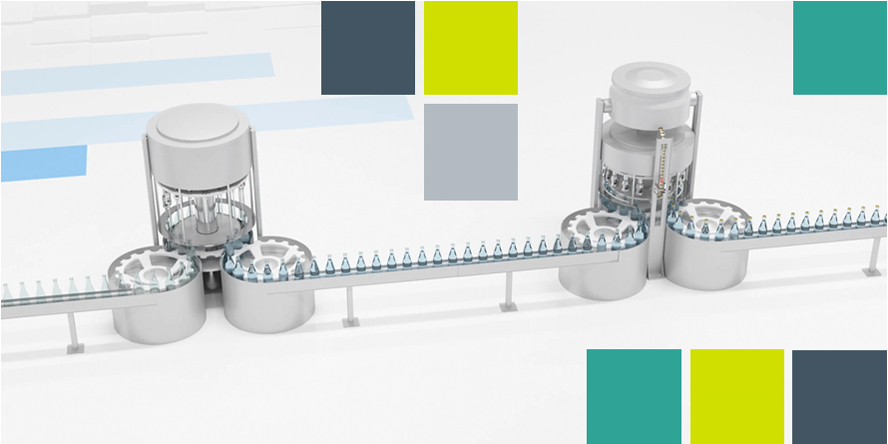

Fully automated filling systems are among the most advanced in modern packaging technology. Whether in the food and beverage industry, the pharmaceutical sector, or the cosmetics industry, these systems handle highly dynamic processes in which precision, speed, and reliability are crucial. Every hour, tens of thousands of bottles, cups, or cans are filled, sealed, and packaged. To ensure that this runs smoothly, high-performance sensor technology plays a central role.

Photoelectric sensors from Pepperl+Fuchs ensure that every step of the process, from filling and sealing to secondary packaging, runs safely and efficiently. They reliably detect transparent objects such as bottles or films, count containers accurately, and monitor the cap feed in the high-speed capping process. In this blog article, we will highlight three key applications of photoelectric sensors in automated filling systems.

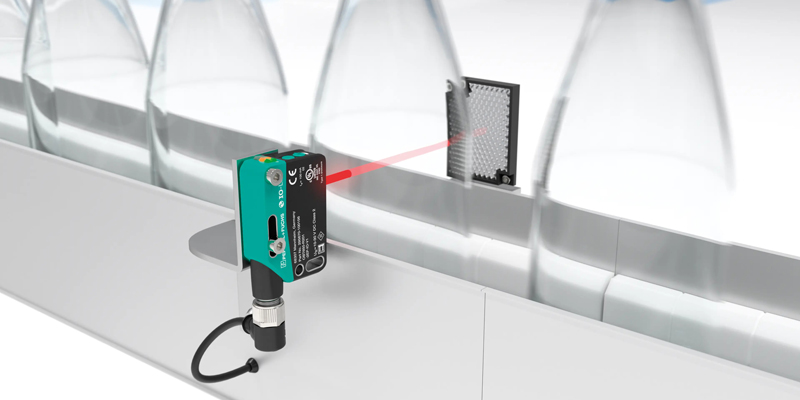

Trouble-Free Filling Process: Reliable Detection of Transparent Bottles

Transparent glass and PET bottles create a particular challenge in filling plants, as they have a depolarizing effect and cause reflections and unwanted focus effects, all of which can trigger false switching. The miniature OBG5000-R100 series or the compact OBG8000-R200 and R201 series retroreflective sensors are ideally suited for this purpose. These ensure a trouble-free filling process, as they not only monitor the bottle flow and count the bottles, but also control the infeed in front of the beverage fillers to prevent bottle jams. By using the circular polarization filter or the clear glass detection operating mode, the sensors reliably detect transparent objects such as clear glass and transparent PET bottles. Users benefit from:

- Two operating modes in one device: clear glass detection or standard reflex mode with long range

- High IP69K degree of protection: ideal for high-moisture areas in the beverage industry

- IO-Link interface: for simple parameterization and diagnostics

- Especially compact designs: ideal for tight installation spaces

The R201 retroreflective sensor reliably detects clear glass or PET bottles, ampoules, and other transparent vials, ensuring a smooth filling process.

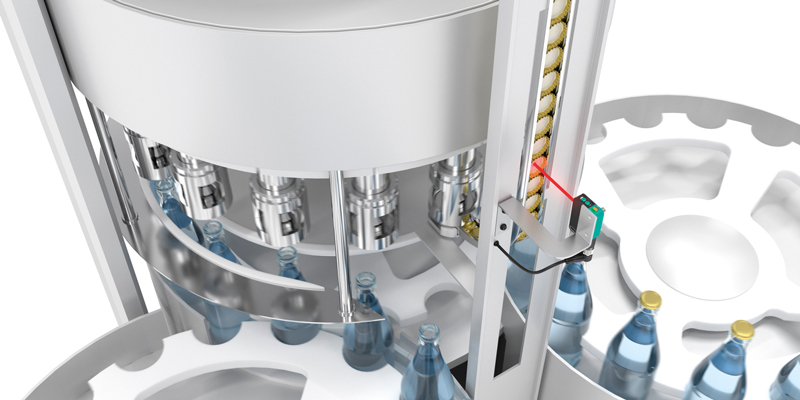

Reliable Sealing: Automated Lid Feeding in High-speed Processes

Immediately after filling, the next crucial step follows: the bottles are sealed in a high-speed capping process. Here, a R201 series diffuse mode sensor monitors the automated cap feed.

Due to multiple switch points, the sensor checks the correct rotational position of the caps and detects damaged or missing caps before they reach the capping machine. This reliably prevents process interruptions and ensures consistently high production quality.

The integrated IO-Link interface allows process data to be evaluated in real time, which is an important advantage for predictive maintenance concepts and for reducing downtime. The result: maximum process reliability and consistent packaging quality, even at high throughputs of up to 60,000 bottles per hour.

The R201 series diffuse mode sensor ensures reliable lid feeding in high-speed sealing processes.

Reliable Film Tear Control: Error-Free Packaging with PET Film

In the final production step, secondary packaging, individual bottles or containers are combined into bundle packs, such as six-packs shrink-wrapped with PET film. Here, retroreflective sensors from the R201 series and a paired reflector with a circular polarization filter ensure reliable detection of the transparent film as it enters the shrink unit. If a film tear is detected, the system stops automatically before defective bundles are produced.

The R201 retroreflective sensor ensures reliable detection of the transparent film and eventual film tears before bottles enter the shrink unit.

Future-Oriented Sensors for Packaging Technology: the R10x and R20x Series from Pepperl+Fuchs

With the R10x and R20x series, Pepperl+Fuchs has created a pioneering sensor range that takes efficiency and flexibility in packaging technology to a new level. The compact R100, R101, and R103 series are suitable for applications with shorter sensing distances and detection ranges, while the medium-sized R200 and R201 series can handle larger working distances.

These powerful sensors offer:

- All functional principles with a uniform operating concept and identical detection modes across all sizes

- High-precision distance measurements up to 10 m, with reflector up to 60 m

- Powerful technologies such as Pulse Ranging Technology and multipixel technology solve even the most demanding measurement and detection tasks

- Flexible mounting concepts through especially compact designs and swiveling plugs

- Easy system integration enabled by IO-Link interface

Future-oriented, versatile, and reliable photoelectric sensors of the R10x and R20x series from Pepperl+Fuchs.

A special feature: The switching sensors of the R10x series can detect and evaluate two different distance measurements and output them as independent switch points simultaneously. This allows two process steps to be automated with just one device. For example, the sensor can detect the stack height in the container and simultaneously request the next container. This not only halves the hardware and cabling costs, but also increases efficiency and plant availability. This is made possible by the compact measurement core of the R10x series with multipixel technology (MPT).

Pepperl+Fuchs photoelectric sensors can be used to reliably perform even complex detection tasks in the smallest of spaces—a decisive advantage in modern filling and packaging systems. Whether for bottle detection, automated cap feeding, or film tear detection, photoelectric sensors from the R10x and R20x series ensure trouble-free operation of fully automated filling systems. Their high precision, robust design, and intelligent signal processing make them the ideal solution for demanding applications.

Subscribe to our newsletter and receive regular news and interesting facts from the world of automation.