Multipixel Technology vs. Pulse Ranging Technology—a Comparison of Two Photoelectric Measuring Principles

Content of This Article

Multipixel Technology vs. Pulse Ranging Technology—a Comparison of Two Photoelectric Measuring Principles

Whether at close range or at distances of up to several hundred meters—photoelectric sensors with Multipixel Technology (MPT) and Pulse Ranging Technology (PRT) enable reliable and precise object detection and offer several advantages at the same time. With the help of the integrated measuring technologies, the distance to the object is detected with pinpoint accuracy and evaluated immediately, so that faults can be detected and rectified at an early stage. Both measurement technologies are largely insensitive to external influences and deliver precise measurement results even on difficult object surfaces.

In this blog article, you can find out more about how sensors with MPT and PRT work and for which applications the respective technologies are suitable.

How Do Sensors with Multipixel Technology Work?

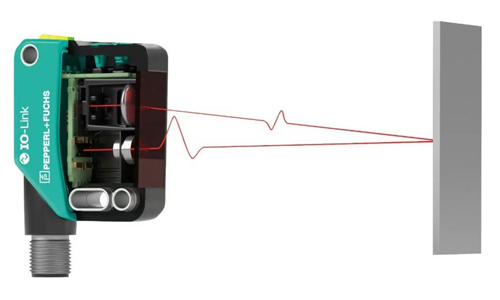

Multipixel Technology combines the proven triangulation principle with the measuring functionality of classic distance sensors. For this purpose, the so-called PowerBeam (an LED or a laser) emits a beam of light onto the object to be detected, which reflects it. The reflected light beam is detected again by a receiving element in the sensor, the multipixel array. Finally, the distance to the object is measured using a precise angle measurement within triangles.

Depending on the distance between the sensor and the object, the reflected light hits different positions on the multipixel array: If the object is close, there is a large angular change. If it is further away, there is a smaller angular change.

The exact distance of the object to the sensor can then be determined using the angular relationship and the determination of the light spot position on the receiving element. This is done fully automatically using the integrated microprocessor and coordinated software algorithms.

The powerful sensors with MPT effortlessly master complex object detection tasks at close range and deliver reliable and interference-free measurement results even under changing ambient conditions.

Sensors with Multipixel Technology in Use

Detection of Different Stack Heights

When loading containers in conveyor technology, the R10x series sensors can use MPT to detect and evaluate two different distance information and output two switch points in each case. This means that the stack height can be detected in one step and the next container can be requested at the same time. Learn more.

The R10x series MPT sensors reliably detect different stack heights.

Reliable Quality Control

Reliable detection of the smallest objects is crucial for the smooth operation of automated processes. Even the smallest positioning errors or missing parts can interrupt the entire assembly or packaging process.

The R10x sensors with MPT can detect even minimal position and orientation deviations with micrometer precision. Learn more.

The R10x sensors with MPT are a reliable solution for quality control.

Precise Position Control of Components

In order for robots to work safely and reliably in a welding cell, it is necessary to determine the exact position of the parts to be removed. The R201 series diffuse mode sensors with MPT offer interference-free distance measurement at close range, from which the robot controller determines the optimum gripping coordinates. Learn more.

The R201 series diffuse mode sensors with MPT precisely detect the position of components.

Advantages of Multipixel Technology at a Glance

- Precise object detection at short distances, even with reflective or dark object surfaces

- Ignoring interfering objects in the detection area through customizable operating modes

- Reliable operation in demanding environments such as deep-freeze applications down to -30 °C

How Do Sensors with Pulse Ranging Technology Work?

With the help of PRT, distances from a few centimeters to several hundred meters can be detected with pinpoint accuracy. To do this, a powerful light source emits short, high-energy pulses that are reflected by the object, or a reflector, and detected again by a light-sensitive receiver element.

The distance to the object is calculated from the values determined using the transit time of the light pulses. If the object is close, the light travel time is short. If it is further away, the light propagation time is longer.

The distance sensors equipped with Pulse Ranging Technology offer reliable and highly precise measurements with high repeat accuracy and short response times. As external interferences such as ambient light or varying reflection properties have hardly any influence on the functionality of the PRT sensors, they are suitable for use in a wide range of ambient and object conditions.

Sensors with Pulse Ranging Technology in Use

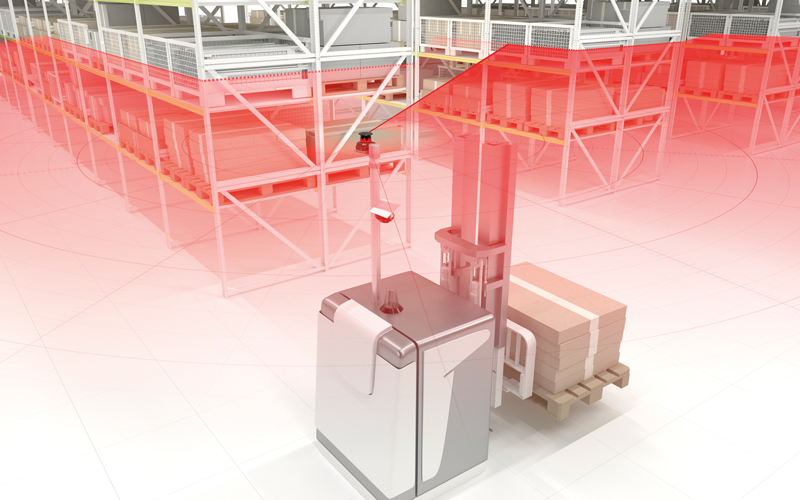

Millimeter-Precise Navigation of AGVs

Automated guided vehicles (AGVs) are increasingly taking over the transportation of goods in warehouse and production logistics. The R2000 2-D LiDAR sensor with PRT and 360° all-round visibility provides position data with millimeter accuracy and enables precise AGV control without delay. Learn more.

The R2000 2-D LiDAR sensor with PRT is an ideal solution for precise navigation of AGVs.

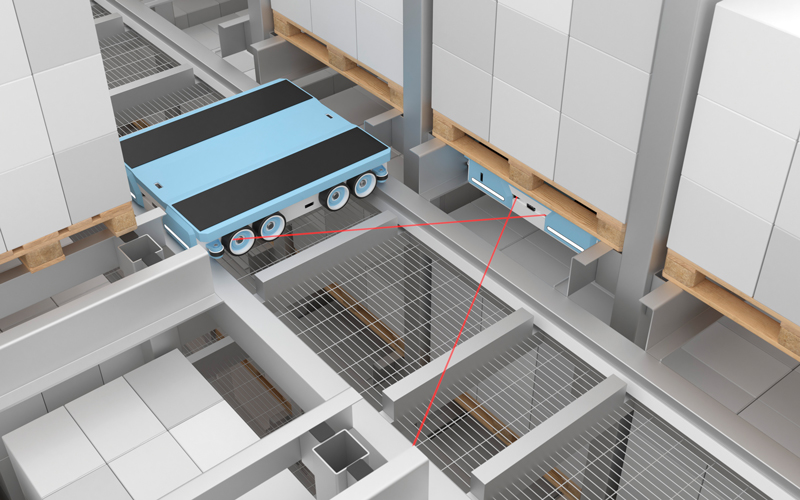

Precise Distance Measurement in Warehouses

Many automated applications require precise and fast distance measurement that also works over long distances. The compact R200 distance sensor with PRT ensures that shelf shuttles move reliably through warehouses and across multiple levels. Learn more.

The R200 distance sensor with PRT ensures precise distance measurements in warehouse applications.

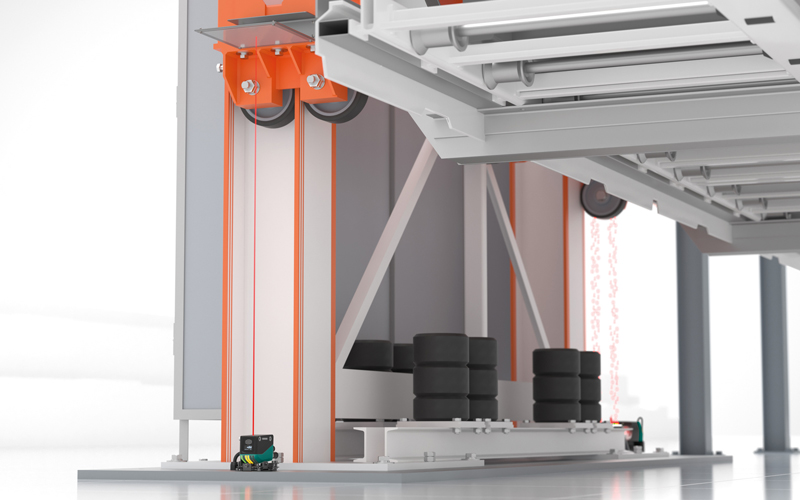

Reliable Positioning of Lifters

In body construction, car bodies are transported in lifters over several levels. Here, the R1000 distance sensor with PRT enables particularly fast and precise positioning, even over long distances. Learn more.

The R1000 distance sensor with PRT ensures presice and reliable positioning of lifters.

Advantages of Pulse Ranging Technology at a Glance

- Precise measurement results over long distances, even with several targets in the detection range

- Insensitive to external influences such as ambient light, dust, or fog and reliable masking of objects in the background

- Reliable operation even in demanding environmental conditions such as deep-freeze applications down to -30 °C

Subscribe to our newsletter and receive regular news and interesting facts from the world of automation.