Intrinsic Safety Barriers for Valve Positioner Control and Monitoring

Content of This Article

- Similarities of K-System KCD2-SCS* and H-System HiC2422 Isolated Barriers

- K-System Intrinsic Safety Barriers: Tailor-Made for Smaller Systems

- H-System Intrinsic Safety Barriers: Best for Larger, Integrated Plants

- Summarized: K-System or H-System—Which Intrinsic Safety Barrier Should You Choose?

- More Information

Intrinsic Safety Barriers for Valve Positioner Control and Monitoring

Valve positioner control and monitoring are common applications in process plants. Positioners ensure that a valve actuator reaches the position specified by the control system using analog indicators for feedback, such as stroke or rotation angles. In the past, a separate isolator module was needed for the input and output signal. The K-System KCD2-SCS* and H-System HiC2422 isolated barriers integrate these functions into one device. Two freely configurable channels allow positioner control on one channel (AO), and position monitoring (AI) on the second channel.

Both intrinsic safety barriers, KCD2-SCS* of the K-System and HiC2422 of the H-System, are characterized by a high degree of functionality and are designed to simplify control and monitoring tasks. However, each system offers its individual benefits. Learn more about the similarities and differences, and which interface module is the best choice for your demands.

Pepperl+Fuchs isolated barriers KCD2-SCS* and HiC2422 provide a dual functionality for positioner control and monitoring with only one device.

Similarities of K-System KCD2-SCS* and H-System HiC2422 Isolated Barriers

Both the K-System KCD2-SCS* and H-System HiC2422 isolated barriers are primarily used for controlling (AO) and monitoring (AI) HART valve positioners. Positioners are used in process control systems to maintain a desired process variable such as flow rate, temperature, or pressure by adjusting the opening or closing of the valve. The isolated barriers ensure safe electrical separation between potentially hazardous field circuits and the control system. Some of their shared features are:

- Ex i Field Circuits: Both systems have intrinsically safe (Ex i) circuits designed for Div. 1 and Zone 0 hazardous areas.

- Signal Isolation: Both isolated barriers provide superior galvanic isolation, ensuring that field signals do not interfere with control signals, and vice versa.

- 2-Channel Modules: Both modules allow for the connection of two separate field instruments. With only a 12.5 mm footprint, this allows for the highest channel density on the market.

- Channel Flexibility: Each channel can be configured separately by signal type via DIP switches.

- Functional Safety Rating: Both modules are rated for SIL 2 (SC3) for installation in safety systems.

- HART transparent: Both models are HART compatible, and can be used with SMART 4 … 20 mA transmitters and valve positioners.

K-System Intrinsic Safety Barriers: Tailor-Made for Smaller Systems

The K-System KCD2-SCS* isolated barriers operate as transmitter power supply and current driver for positioners. They are ideal for smaller systems such as control cabinets or field boxes. Some of its features and advantages are:

- Compact Design: Measuring 12.5 x 124 x 114 mm, the KCD2-SCS* is compact, making it ideal for tight spaces and control panels.

- Mounting Flexibility: The K-System barriers are mounted on DIN rails, allowing for flexible installation in a variety of enclosures.

- Power Supply: The system can be powered via terminal or bus connections or Pepperl+Fuchs’ Power Rail system.

- Field and Control Side Connections: The K-System offers the option of pluggable screw, or spring terminals on both the field and control sides, ensuring that installation is quick and user-friendly.

- Wiring Configuration: Each K-System isolated barrier is wired individually, providing a straightforward wiring process.

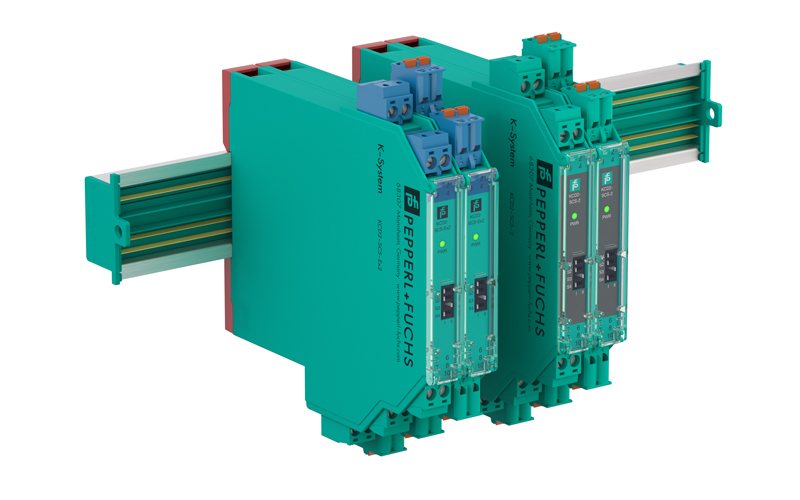

The KCD2-SCS* isolated barriers of the Pepperl+Fuchs K-System mounted on a Power Rail system.

The KCD2-SCS* isolated barriers of the K-System offer variants for hazardous and non-hazardous areas. The KCD2-SCS-Ex2 is an isolated barrier for intrinsically safe signals and the KCD2-SCS-2 is designed for signals to or from non-hazardous areas. For small- to medium-sized installations where space is limited and system complexity is lower, the K-System is the first choice.

H-System Intrinsic Safety Barriers: Best for Larger, Integrated Plants

The H-System HiC2422 isolated barrier is designed to handle the complex needs of medium to large plants in combination with process control systems. Due to its dual functionality, it can be used both as a SMART transmitter power supply and as a current driver for valve positioners. The HiC2422 barrier for analog signals features:

- Slim Profile: The HiC2422 has a smaller footprint of 12.5 x 106 x 128 mm, making it ideal for tight installations where space saving is critical.

- Termination Board Mounting: Unlike the K-System, which mounts directly to the DIN rail, the H-System is installed on a termination board. This allows for the bundling of multiple signals into one system connector, significantly reducing wiring complexity, and allowing for DCS compatibility.

- Power Supply: The H-System is powered through a central terminal with a bus on the termination board, simplifying the management of power distribution across multiple devices. There are two sets of fused power terminals for redundant power supply connections

- Optimized for DCS/ESD Systems: Because of the ability to provide control-system specific connectors, the H-System can be used in direct connection with Distributed Control Systems (DCS) and Emergency Shutdown Systems (ESD), making it ideal for larger systems.

- High Efficiency in Large Plants: The system’s design allows for fast and error-free wiring to control systems, which is important in large-scale operations that require highly reliable and efficient signal transmission.

- Safe Wiring Distribution: The termination board design allows for clear separation of intrinsically safe and non-intrinsically safe wiring to allow for safe and easy panel layout in the installed enclosure.

- Fixed Ex-rated terminals: The intrinsically safe terminals are fixed to the termination board providing secure connections to the field instrument in the hazardous location.

The H-System is tailored to hazardous environments, especially in larger plants. Its central terminal power supply and reduced wiring complexity make it the most efficient solution for medium to large plants.

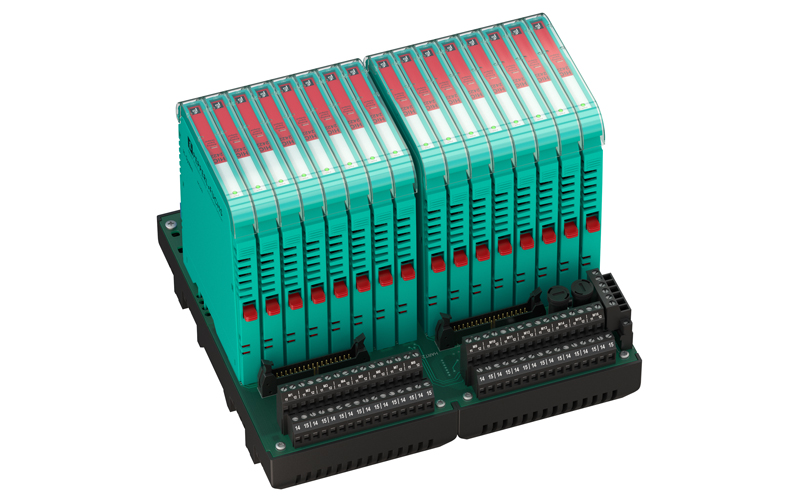

The HiC2422 isolated barriers of the Pepperl+Fuchs H-System mounted on a termination board.

Summarized: K-System or H-System—Which Intrinsic Safety Barrier Should You Choose?

When deciding between K-System and H-System intrinsic safety barriers, in the end the choice depends on the size and complexity of your plant.

- Choose the K-System for smaller installations where flexibility and user-friendliness are most important. It is ideal for control cabinets, field boxes, and other compact environments.

- Choose the H-System as the most suitable solution in medium to large plants that require efficient signal processing and centralized power supply, especially in hazardous environments.

Pepperl+Fuchs has the largest portfolio of intrinsic safety barriers on the market. Both the KCD2-SCS* and HiC2422 isolated barriers offer unique features with the highest safety and performance standards. Due to their dual function in one device, they reduce inventory and ensure cost savings. By knowing the features of each system, you can ensure maximum performance for your plant.

Subscribe to our newsletter and receive regular news and interesting facts from the world of automation.