Automation of Mining Stockyard Machines

Content of This Article

- Exact Machine Positioning: RFID Read/Write Devices and Rotary Encoders

- Collision Protection: Ultrasonic Sensors

- Monitoring of Boom Inclination and Movement: Inclination Sensors

- Monitoring of Cable Reel and Wheel Assembly: Inclination Sensors, IO-Link Vibration Sensors, and IO-Link Rotary Encoders

- Defining Operational Boundaries and Detect Moving Parts: Inductive Sensors

- Pepperl+Fuchs’ Role on the Road to Automation in Mining

- More Information

Automation of Mining Stockyard Machines

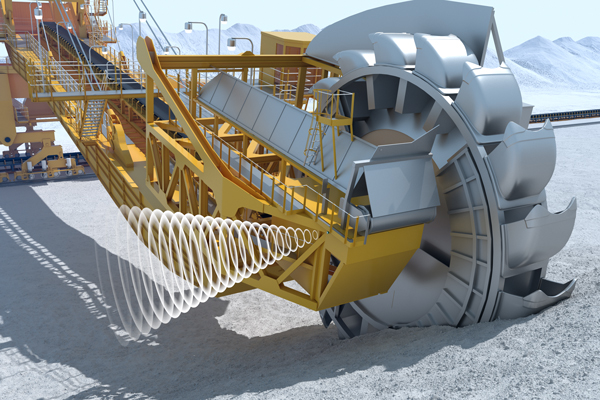

Automated stockyard stackers and reclaimers are complete stockyard and stockpile management systems that can optimally manage and automate the inbound receipt and outbound delivery of mined material. These stockyard machines are designed to work with any mined material. The integration of modern sensor technologies optimizes the handling and management of materials in mining stockyards further. Read on and learn in this blog article how various robust Pepperl+Fuchs sensors made to withstand the harsh environmental conditions of the mining industry play an important role in the complete and reliable automation of stockyard machine operations.

Exact Machine Positioning: RFID Read/Write Devices and Rotary Encoders

Accurate and reliable positioning of stockyard machines is the key to smooth operation. RFID (radio frequency identification) tags such as the IUC87-F257-T17-M-FR* together with an RFID evaluation unit (IC-KP2-1HB17-2V1D), an RFID read/write device such as the IUH-F190, and a multiturn absolute rotary encoder (for example ENA58IL or PVM58N) are required to track and confirm the exact position of the machine within the stockyard.

As the machine travels very slowly along the stockyard either “stacking” or “reclaiming” ore, the RFID tags are in fixed positions spaced approximately every 10 to 15 meters along the travel of the machine. The RFID read/write device is attached to the machine as it moves. When the device detects the tag, it has a number (position) which is compared to the multiturn absolute rotary encoder “position”. This confirms the position of the machine in the stockyard.

The rugged RFID read/write devices have IP67 degree of protection to withstand the dusty and dirty environments found in mining locations. They enable a reliable reading of the tags, ease of integration, and high repeat accuracy. Access to the free Pepperl+Fuchs RFIDControl software is an additional advantage, providing customers with valuable tools for efficient control system management. Moreover, the software provides access to all components without using a PLC. Integration with the PLC is possible via the IDENTControl interface modules or via EtherNet/IP, PROFINET, MODBUS TCP, TCP/IP, PROFIBUS, EtherCAT, and Serial.

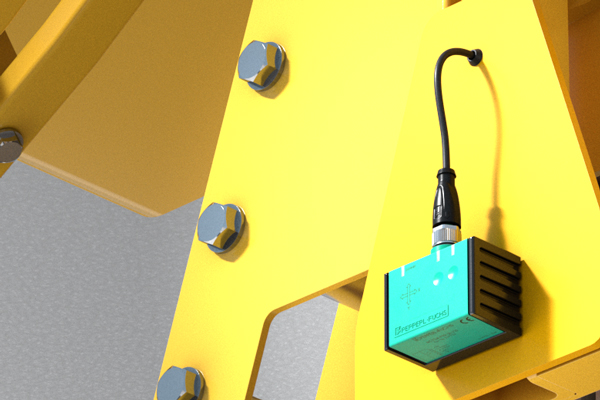

Collision Protection: Ultrasonic Sensors

In a challenging environment such as a mining stockyard, the risk of collisions between the machine boom and uneven stacks of material such as ore is a major concern. For this reason, ultrasonic sensors such as the UC6000-30GM-2EP-IO-V15 are used for collision protection. These sensors continuously monitor the surroundings and detect the presence of material stacks in the machine’s travel path. In the event of an impending collision, the ultrasonic sensors trigger immediate corrective action, preventing damage to the machine and ensuring a safer working environment for mine workers.

Monitoring of Boom Inclination and Movement: Inclination Sensors

Monitoring the inclination of the machine’s boom is critical for both operational efficiency and safety. Inclination sensors such as the INY360D-F99-2I2E2-5M are used to track the angle of the boom, providing real-time data on its position. This information is crucial for optimizing material transport processes and ensuring precise placement of materials. By actively tracking the inclination of the boom, mining operators can proactively address potential issues even during movement.

Monitoring of Cable Reel and Wheel Assembly: Inclination Sensors, IO-Link Vibration Sensors, and IO-Link Rotary Encoders

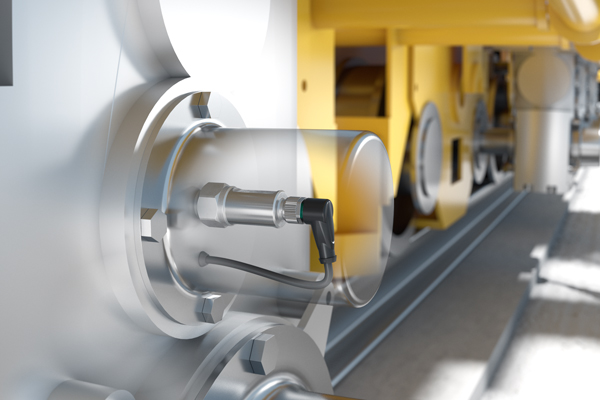

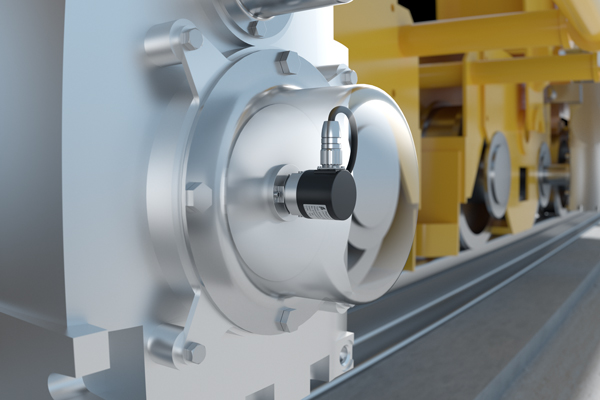

Pepperl+Fuchs sensors such as an IO-Link vibration sensor (VIM32PL-E1AC8-0RE-IO-1V1401), an IO-Link multiturn absolute rotary encoder (ENA58IL*IO-Link) and an inclination sensor (INY360D-F99-2I2E2-5M) are used to monitor the wheels and the condition of the cable reels of the stockyard reclaimer.

The vibration sensor is attached to a critical part of the machine, such as the wheel assembly. As the machine moves, the sensor detects vibrations and changes in acceleration. The IO-Link communication protocol allows the sensor to transmit detailed information about the vibrations to the control system. By analyzing the vibration data, the system can identify potential issues such as imbalances, misalignments, or excessive wear in the wheel components.

An absolute rotary encoder is typically installed on one of the machine’s wheels to measure its rotational movement. As the wheel turns, the rotary encoder generates electrical pulses that are sent to the control system via the IO-Link interface. The control system can use this information to calculate the speed and direction of the wheel rotation. Monitoring the rotational data helps ensure that the wheels are moving at the desired speed and provides important feedback for navigation and control algorithms.

The inclination sensor measures the tilt or inclination of the wheel assembly, ensuring it operates within specified angles to maintain stability and prevent potential hazards.

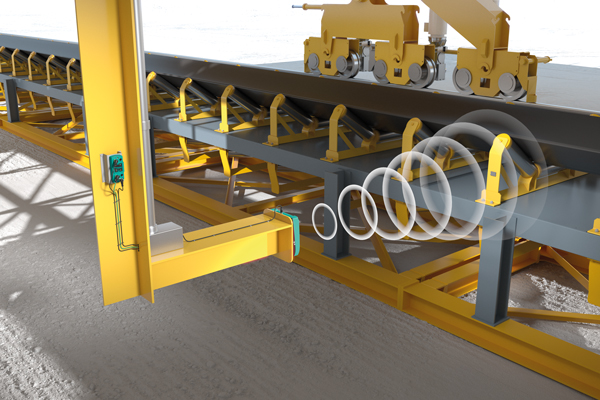

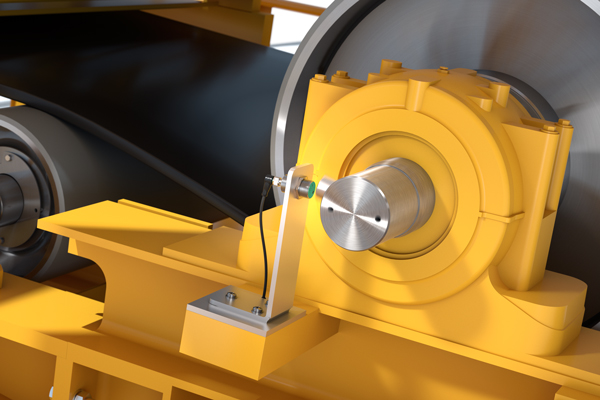

Defining Operational Boundaries and Detect Moving Parts: Inductive Sensors

Robust inductive sensors with IP67 degree of protection such as the NBB10-30GM40-Z0-V1 are indispensable in stockyard machine automation, serving multiple purposes. As machine limit switches, they define the operational boundaries of the equipment, preventing overextension or unintended movements.

Additionally, inductive sensors are used to detect the motion of various machine components. This ensures that all moving parts are operating within predefined parameters, contributing to the overall safety and longevity of the equipment.

Pepperl+Fuchs’ Role on the Road to Automation in Mining

The integration of Pepperl+Fuchs sensors and solutions mentioned in this blog article is advancing the way stockyard machines operate. As mining companies adopt these technologies, they not only improve their competitive advantage, but also contribute to a safer and more sustainable mining industry.

Subscribe to our newsletter and receive regular news and interesting facts from the world of automation.