Setup, Installation and Commissioning of the 5500-MAN Manifold Valve System for Fully Automatic Pressurized Enclosure Systems

Content of This Article

- Purpose of a 5500-MAN-** Manifold Valve in a Bebco EPS® Purge and Pressurization System

- Setup, Installation and Commissioning of the 5500-MAN-** Manifold Valve

- Mounting Hardware

- Product Overview

- Notes on Explosionproof Wiring and the Temperature Operating Range of the 5500-MAN-CDUL-** Manifold Valves

- More Information

Setup, Installation and Commissioning of the 5500-MAN Manifold Valve System for Fully Automatic Pressurized Enclosure Systems

In this two-part video series, Chris Romano, Product Manager for Purge and Pressurization, demonstrates the 5500-MAN-** manifold valve system: setup, installation and commissioning for fully automatic pressurized enclosure systems of the 5500 and 7500 control units from Pepperl+Fuchs in a live demo.

What is the 5500-MAN-** manifold valve system and how does it work with the 7500 or 5500 control unit? Also, see what is included with this manifold valve system.

Purpose of a 5500-MAN-** Manifold Valve in a Bebco EPS® Purge and Pressurization System

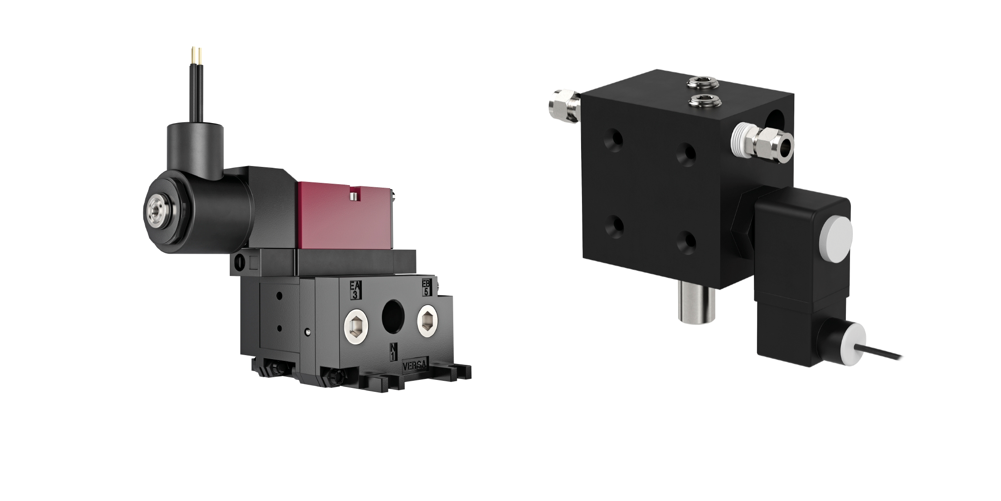

An electrically controllable 5500-MAN-** series manifold valve is designed for Pepperl+Fuchs’ 5500 and 7500 series fully automatic pressurized enclosure systems. The manifold valve system combines a solenoid valve for purging and a needle valve for pressurization in one manifold design. When the manifold valve is energized, the solenoid valve opens and allows for a high flow rate of protective gas into the enclosure. When the manifold valve is de-energized, the flow through the internal needle valve is adjustable by using the included hexagon key. The manifold valve is used for purging, leakage compensation, and temperature control by signals from user-defined points on the 5500 or 7500 control unit of the fully automatic purge and pressurization system.

The electrically controllable manifolds of the 5500-MAN-** series combine a solenoid valve and needle valve in one unit.

Setup, Installation and Commissioning of the 5500-MAN-** Manifold Valve

Part 1 of the video series informs you about the different types of manifold valves and their basic functions as well as areas of application and global certifications. We also go through the hardware that is included with each 5500-MAN manifold valve for easy installation and setup.

Live Demo Part 1: Purpose of a 5500 Manifold Bebco EPS® Purge & Pressurization System | Part 1: Unboxing the 5500-MAN

Part 2 of the video shows the operation of the manifold valve and how to set it up using the 7500 control unit. With an actual purge and pressurization system in operation, you can experience how easy these units are to install, set up, and operate with our 7500 or 5500 control unit for a fully automatic purge and pressurization system.

Live Demo Part 2: Purpose of a 5500 Manifold Bebco EPS® Purge & Pressurization System | Part 2: Live Demo

Mounting Hardware

Mounting hardware includes 3/8″ tube compression fittings mounted on the manifold valve for input and output flow, 3/8″ tube compression bulkhead fitting for getting flow into the enclosure and certified sealing washers with bolts to mount the manifold valve to the enclosure. Also included is 1 meter of 3/8″ poly tubing with 3/8″ poly tube stiffener inserts which allows the connection of plastic tubing to compression fittings without collapsing the tubing.

Product Overview

Notes on Explosionproof Wiring and the Temperature Operating Range of the 5500-MAN-CDUL-** Manifold Valves

Proper wiring of the 5500-MAN-CDUL-**

The 5500-MAN-CDUL-** certification is for explosionproof, Class I, Div. 1, Groups C, D; Class II, Div. 1 Groups E, F, and G; Class I, Div. 2 Groups A, B, C, D.

In the past, there has been some confusion on the requirement for wiring the manifold valve. Every now and then, the assumption was that if the manifold valve is certified for Div. 2, it is non-incendive. However, this is not the case. The wiring of the 5500-MAN-CDUL-** must use explosionproof methods. This requires the wiring in a rigid conduit and a conduit seal within 18” of the manifold valve. This requirement is the same for internal or external mounting of the manifold valve to the purged and pressurized enclosure.

If you require a non-incendive manifold valve, we recommend to use 5500-MAN-CD01-**. This model is CSA- and FM-certified for Class I & II, Div. 2.

Permissible Temperature Operating Range (T-Code) for the 5500-MAN-CDUL-**

The 5500-MAN-CDUL-** manifold valve certification has a T-code rating of T3C as indicated on the datasheet. This means that this system is not suitable for applications where a T4 rating is a requirement.

For T4 applications, the manifold valves 5500-MAN-CD01-** are recommended, which are CSA- and FM-certified for Class I & II, Div. 2, non-incendive.

More Information

Subscribe to our newsletter and receive regular news and interesting facts from the world of automation.