RFID Meets AGV—Three Examples of Practical Applications

Content of This Article

RFID Meets AGV—Three Examples of Practical Applications

Whether as practical automated guided carts, rolling assembly platforms, or massive self-driving container tank transporters, automated guided vehicles (AGVs) in all possible designs have become indispensable elements in modern production processes that follow the Industry 4.0 principle. They help to make everyday work significantly easier, preserve existing resources, and speed up transport processes considerably. They differ widely in appearance, and the technologies that enable the vehicles to work automatically or autonomously are highly diverse. RFID is often used, and when applied intelligently, this radio-based identification method can perform numerous tasks on the AGV. This blog article presents three possible versions.

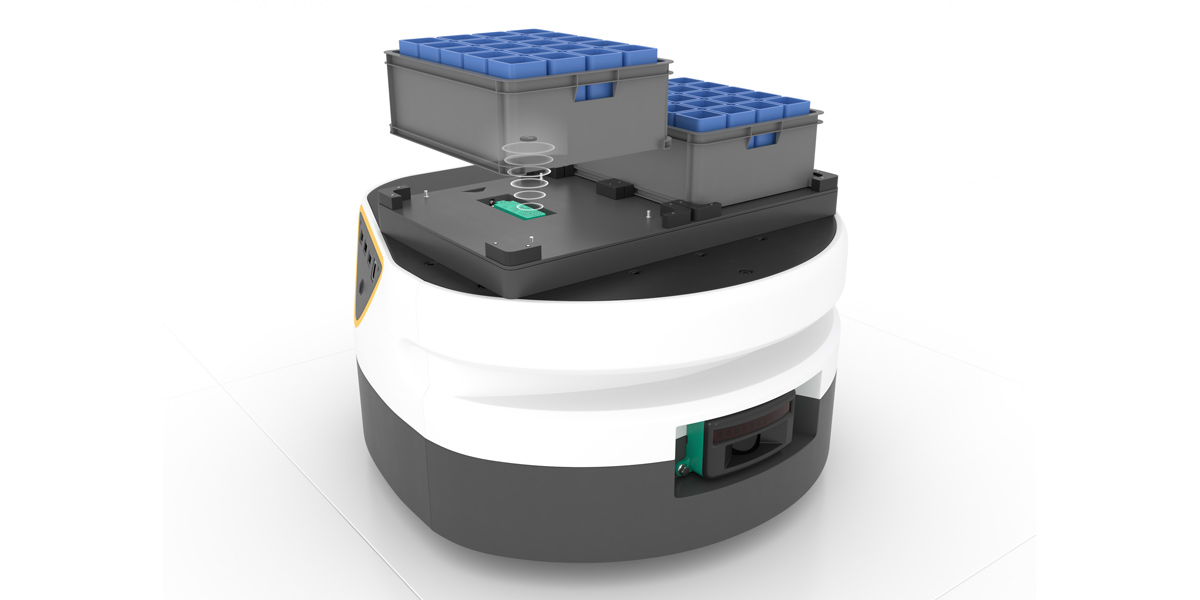

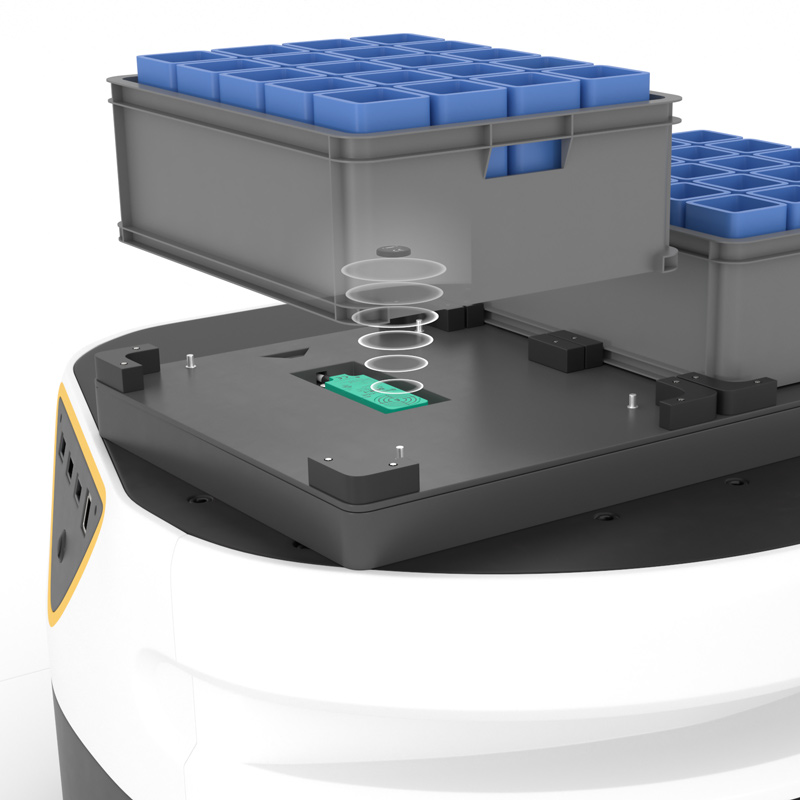

1. HF-RFID for Precise Identification on Bots

RFID in the high-frequency range (HF-RFID) provides an effective way to enable smaller bots to detect loads. An extremely compact HF-RFID read/write head is installed on top of the vehicle to detect the boxes placed there, which are equipped with an RFID tag on the underside. Since the HF-RFID read/write head spans a precisely defined sensing range of up to just 55 mm, only the RFID tag of the load carrier that is actually relevant is detected and the risk of an incorrect assignment is minimized. This ensures the correct flow of materials in production at all times.

The HF read/write head F61 enables reliabe load detection

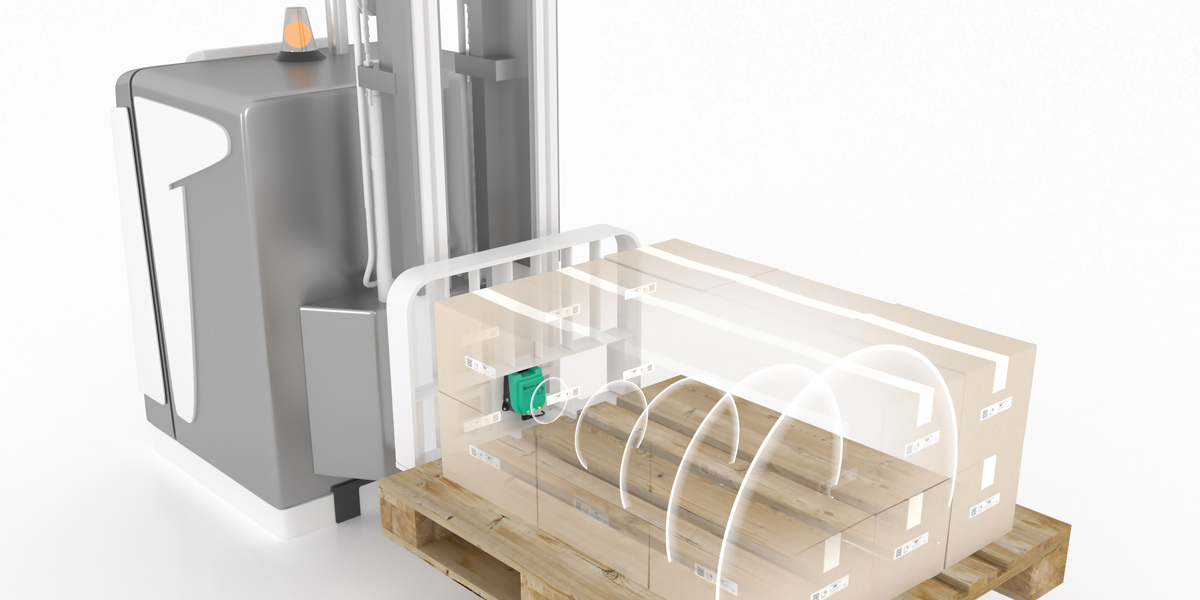

2. UHF-RFID for Load Detection on Pallets

If a large number of objects need to be identified synchronously in the production process, RFID in the ultra-high frequency range (UHF-RFID) is a suitable option. If an autonomous forklift is equipped with an industrial UHF read/write head in the fork carriage, this can detect all packages on a pallet in a single read operation using multi-tag detection. This enables the transparent and complete tracking of items that are booked in or out of the warehouse management system. The high transmission power of the UHF read/write head allows the RFID tags to be detected as soon as the AGV approaches the load carrier, without causing a loading delay. The integrated antenna polarization with automatic switching enables reliable identification of tags in unknown or inconsistent positions.

The UHF read/write head of the F190 series reliably detects all palletized packages in a single read operation.

3. safe positioning thanks to RFID

Last but not least, when using AGVs, the safety of employees must also be ensured at all times. RFID offers valuable support here, with the choice falling on a different frequency range and corresponding components depending on the range and ambient conditions. A typical application is the safe switching off or switching over of the safety fields of the AGV when picking up loads, at transfer points or in doorways. This requires safe determination of the position of the AGV, which can be achieved, for example, by combining the position data from LiDAR sensors frequently used on AGVs for navigation with information from RFID transponders embedded in the ground. If the AGV is not equipped with a LiDAR sensor, a redundantly designed RFID solution also opens up the possibility of achieving the required safety level. When implementing such safety applications, it is important to consult with a partner who ideally offers not only PL- or SIL-compliant components, but also further support on the subject of safety.

Transponders embedded in the floor support the exact positioning of AGVs

Success through Versatility

These examples demonstrate the versatility of RFID. As the only technology that can reliably read and write tags without a line of sight, it contributes significantly to increasing the efficiency and safety of AGVs in the field of Industry 4.0. Tags, read/write heads, interfaces, and different bus and software systems are available in a wide range of designs. The possibilities are practically endless when it comes to integrating RFID into any type of AGV.

Subscribe to our newsletter and receive regular news and interesting facts from the world of automation.