Line Fault Detection without Additional Wiring

Content of This Article

Line Fault Detection without Additional Wiring

From the recording of the process variable to the evaluation in the control system, many errors can occur that can lead to unwanted process states. These can result in plant shutdowns or quality problems, and even pose hazards to people and the environment. In addition to faults in the device itself, isolators also monitor the connecting lines between the isolator, the field device and the control system for lead breakage or lead short circuits, depending on the device variant. In this blog post you can find out how isolated barriers from Pepperl+Fuchs detect line faults in the signal circuit without additional wiring.

So what happens if the wiring connecting of the field device to the isolator is interrupted or accidentally shorted? When the circuit is checked for functionality, in many cases we find that the field device and controller are working properly, however, the correct I/O information is not recognized by the controller. The cause is often that there is a fault in the field wiring. Appropriate fault detection and analysis by measuring device in the plant is usually very costly and can cause functionality problems within the application. The problem is that a line fault is only detected when the system malfunctions and then an emergency situation must be responded to quickly. Manual troubleshooting in the plant thereby costs unnecessary downtime.

Line Fault Detection with Isolated Barriers from Pepperl+Fuchs

The ideal solution to this problem is provided by the Pepperl+Fuchs isolated barriers with integrated line fault detection. Fault monitoring is not only possible with intrinsically safe barriers for hazardous areas, but also with the corresponding non-Ex devices.

The isolator monitors the current levels. Exceeding an upper threshold is interpreted as a short circuit. If the level falls below a lower threshold, there is a lead breakage.

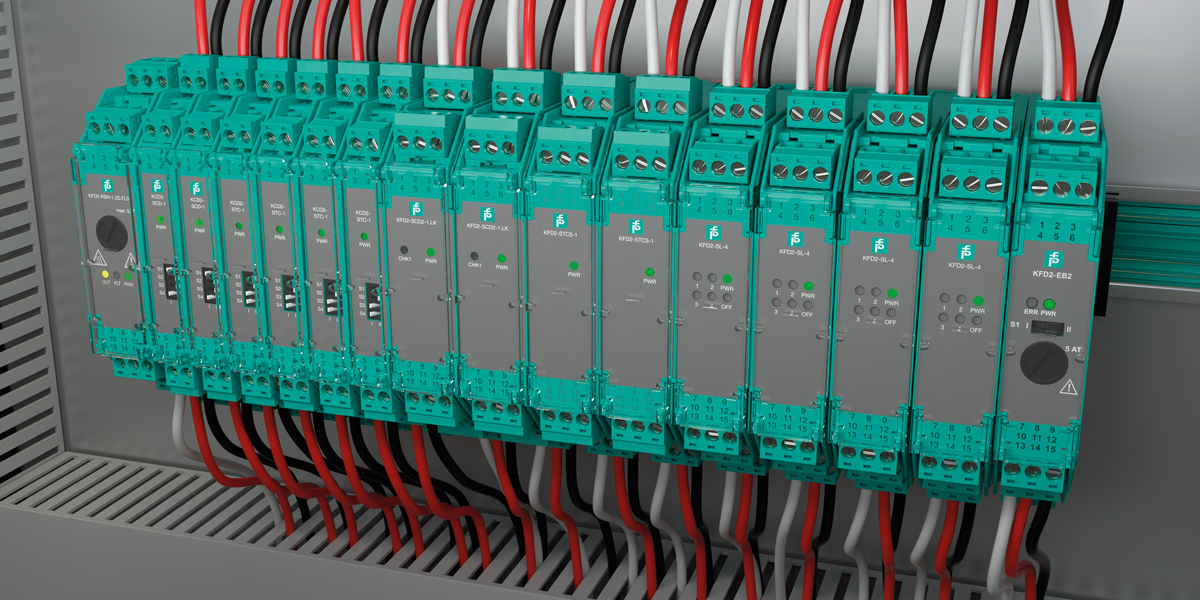

The error message is output via a red error message LED on the module and as a collective error message on the power supply module. The KFD2-EB2 power supply module is connected to the modules via the UPR-03 Power Rail and indicates a fault in the module group it is monitoring: The error can then be assigned to a signal circuit via the LED on the module – without additional wiring.

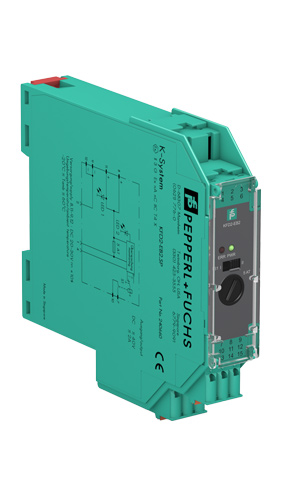

The power feed module KFD2-EB2 shows all error messages of modules that are supplied via it. In addition to device errors, line faults are also signaled by the “ERR” LED.

Pepperl+Fuchs models with “.LB” in the type code have an additional output: The fault signal output is active in the normal state and drops out in the fault state (closed-circuit current principle).

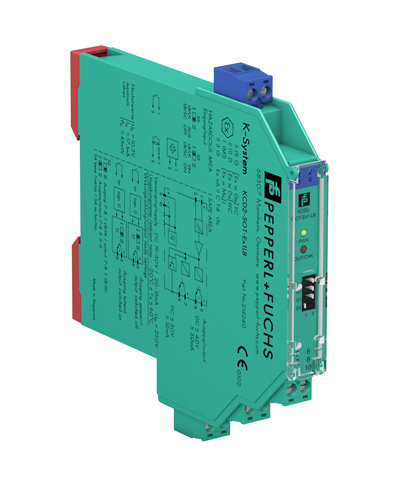

The switch amplifier KCD2-SOT-Ex1.LB has two separate outputs, for example for use as a splitter. However, the second output can also be used as an error message output. Using the switches on the front panel, the second output can be selected as an error message output and the line fault detection can be switched on or off. Line faults are indicated via the “OUT/CHK” LED.

More Information

- Switch Amplifiers of the K-System (DIN Rail Mounting) with LFD

- Isolated Barriers of the K-System (DIN Rail Mounting) with LFD

- Isolated Barriers of the H-System (Termination Board Mounting) with LFD

- Signal Conditioners of the K-System with LFD for non-Ex areas

- Signal Conditioners of the SC-System (DIN Rail Mounting) with LFD for non-Ex areas

Subscribe to our newsletter and receive regular news and interesting facts from the world of automation.