Ultrasonic Sensor FAQ: Mounting Tips

Content of This Article

Ultrasonic Sensor FAQ: Mounting Tips

In industrial plants, correct mounting is just as important as selecting the right sensor. We have answered some frequently asked customer questions below so that you can avoid incorrect measurement results in your plant.

1. what must be observed when mounting ultrasonic sensors in parallel?

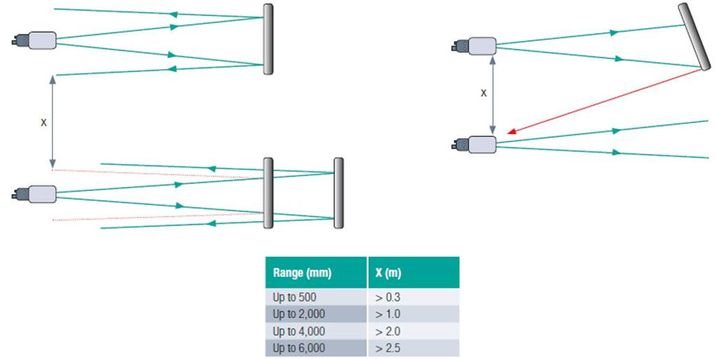

Minimum distances for parallel mounting of ultrasonic sensors

To prevent mutual interference, the minimum distances between ultrasonic sensors of the same type specified in the following figures must be observed. The specified values are to be understood as guidelines. They apply if the beam angles are aligned parallel to each other and the surfaces of the objects are at right angles to the axes of the beam angles. Otherwise, the actual required distance “X” must be determined experimentally. This depends on the orientation, type and surface of the target objects to be detected which are located within the sound lobe.

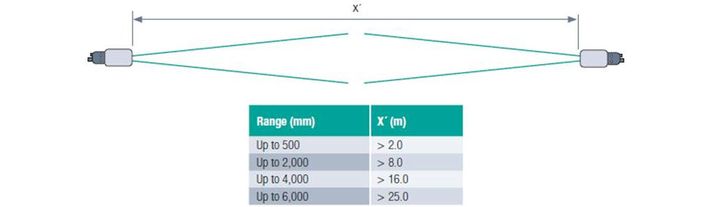

Minimum distances when mounting ultrasonic sensors opposite one another

The distances indicated below must be observed for opposite mounting. If faults occur, it may be necessary to increase the distance X or, where appropriate, activate the synchronization or multiplex function. Synchronized and non-synchronized ultrasonic sensors must not be mounted opposite one other.

2. Are sensors/transducers chemically resistant?

In ultrasonic sensors, the ultrasonic transducer is usually the most critical component from a chemical point of view. Standard ultrasonic transducers are chemically resistant to a limited extent due to the materials used there (hollow glass spheres, epoxy resin and PUR foam). If sensors are used in an environment with chemically aggressive substances (acids, alkalis, cleaning agents …), ultrasonic sensors with a higher chemical resistance should be used. This is achieved by coating the ultrasonic transducers with a PTFE film. At the same time, such sensors typically also have a housing made of high-quality stainless steel and are thus suitable overall for such an area of application. If even PTFE is not sufficient as protection against the chemicals, hermetically encapsulated ultrasonic sensors in full stainless steel construction, e.g. the UMC3000 or UMB800 series, are available. In these models, the entire sensor outer skin is made of V4A stainless steel, which guarantees maximum chemical resistance.

Learn more about the UMB800 in our video:

More Information

Subscribe to our newsletter and receive regular news and interesting facts from the world of automation.