Ultrasonic Sensor FAQ: External Influences on Sensor Operation

Content of This Article

Ultrasonic Sensor FAQ: External Influences on Sensor Operation

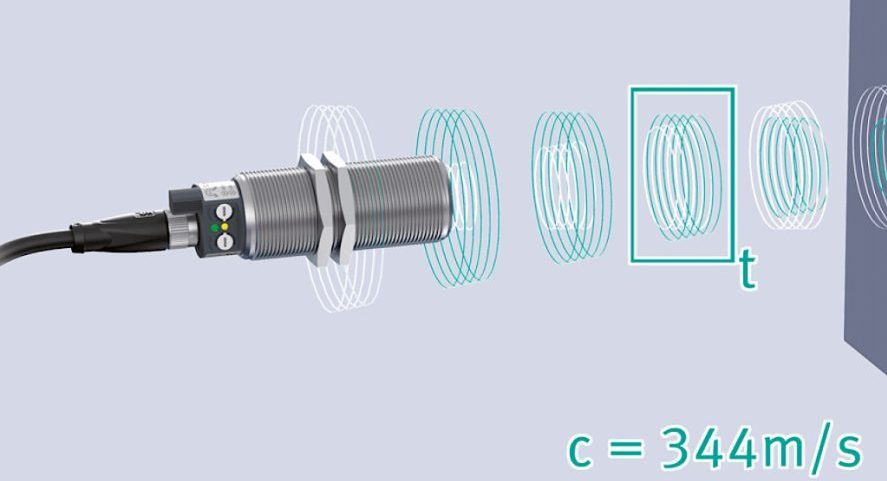

How do temperature, rain, and other external factors influence the performance of ultrasonic sensors? Read the blog article below to find out how ultrasonic sensors from Pepperl+Fuchs handle extreme conditions.

1. Do Temperature and Humidity Affect the Sensor Detection Range?

The relative humidity and temperature of the ambient atmosphere can affect the detection range of the ultrasonic signal. The detection range of an ultrasonic sensor can decrease as the temperature rises and as the humidity increases. However, this reduction is not linear, but differs from sensor to sensor. The nominal detection range of the sensor specified in the datasheet is achieved under all conditions.

From a practical point of view, absolute accuracies of 1-3% are realistic for the industrial use of ultrasonic proximity switches in the operating range from -25°C to +70°C

2. Is the Measurement Affected by Dust, Rain, or Mist?

A very high level of dust, heavy rain, or heavy snowfall can decrease the acoustic energy of the sensor, the size of the sound cone, or the detection range of the sensor. Intense thunderstorms with gale-force winds can cause unstable measurements with loss of signal. However, small deposits on the surface of the transducer, such as dust and dirt, do not affect the runtime measurement. Mist does not affect the quality of the measurement.

3. Which Environmental Factors Affect the Measurement Result of Ultrasonic Sensors?

Air Temperature:

The air temperature has the greatest influence on measurement accuracy. The air temperature changes the speed of sound by 0.17 % per degree Kelvin. To compensate for these effects, almost all ultrasonic sensors from Pepperl+Fuchs have a temperature probe that measures the ambient temperature. This allows the sensor to automatically correct any distortion of the measured values.

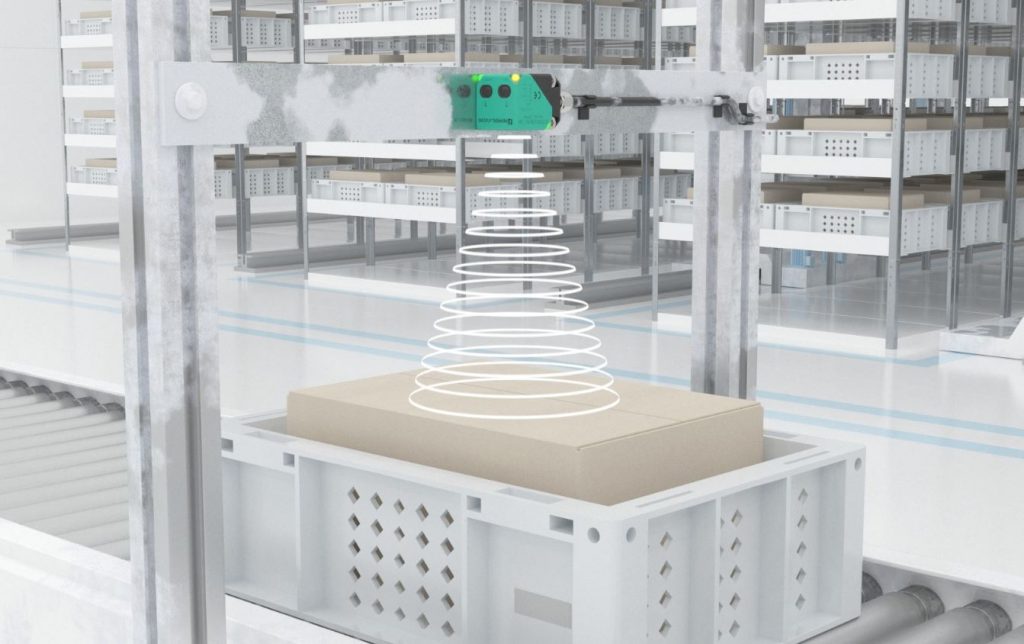

Areas of application for ultrasonic sensors with high temperature tolerance are, for example, deep-freeze warehouses in the food industry.

Ultrasonic sensors from Pepperl+Fuchs operate without any problems in temperatures ranging from -25 °C to +70 °C. Measuring errors due to the low temperatures are compensated by temperature sensors

Humidity:

At room temperature and lower temperatures, humidity has little impact on the speed of sound. However, if the air temperature is higher, the speed of sound increases as humidity increases. Nevertheless, this impact is negligible for typical application areas of industrial ultrasonic sensors and does not need to be compensated.

Barometric Pressure:

The speed of sound decreases by less than 1 % between sea level and 3000 meters altitude. Atmospheric fluctuations at a specific location are also negligibly low and the effects on the speed of sound are scarcely measurable.

Air Currents:

Normal air currents (wind) have no effect on ultrasonic measurement up to speeds of 7 Bft (50 km/h – 61.5 km/h) if the object reflects sound well. Especially hot objects, such as red-hot metal, can result in air turbulence and boundary layers in the air. As a result, the ultrasound can be scattered or deflected so that only echoes that can hardly be evaluated arrive at the sensor or, in the case of a sound deflection, no echo travels back to the sensor.

Paint Mist:

Paint mist, also like weather-related mist, has no impact on the ultrasonic sensors’ function. However, care should be taken to avoid large amounts of paint being deposited on the surface of the transducer. Individual splashes or only a very thin layer of paint on the ultrasonic transducer usually have little or no effect on the function of the sensor.

External Noise:

In general, external noise does not result in malfunctions. However, if the source of disturbance has the same frequency as the ultrasonic sensor, the level of the external noise must not exceed the level of the native echoes. This can occur, for example, when filling a silo with stone products.

4. How Are Ultrasonic Sensors Cleaned?

To some extent, ultrasonic sensors clean themselves via the vibrations of the ultrasonic transducer. Application-related deposits on the sensor can be removed with a soft cloth and water, if necessary. Thin film-like deposits—such as a thin layer of oil—usually do not affect how the sensor functions and do not necessarily need to be removed.

Free PDF Download

More Information

Subscribe to our newsletter and receive regular news and interesting facts from the world of automation.