Ultrasonic Sensor FAQ: Differences between Diffuse Mode Sensor, Retroreflective Sensor, and Thru-Beam Sensor

Content of This Article

Ultrasonic Sensor FAQ: Differences between Diffuse Mode Sensor, Retroreflective Sensor, and Thru-Beam Sensor

Different operating modes can be achieved with ultrasonic sensors with switching output by appropriate construction and configuration. Learn more in this blog article about how diffuse mode sensors, retroreflective sensors, and ultrasonic thru-beam sensors work.

1. What are the differences between a diffuse reflection sensor, a diffuse reflection barrier and a throughbeam barrier?

In the case of the diffuse reflection sensor, the ultrasonic transducer is used as a transmitter and receiver and is usually located together with the evaluation electronics in a common housing. The diffuse reflection sensor requires a reflection (echo) of the emitted sound waves from the object back to the ultrasonic sensor. As soon as an object is within the switching range of the sensor, the distance to the object is determined or a switching process is triggered.

In the case of the reflection barrier, the ultrasonic transducer is also used as a transmitter and receiver. In contrast to the reflection sensor, however, the ultrasonic signal is constantly reflected by a permanently installed reflector – the reference reflector. For example, a plate made of metal or plastic or a background (e.g. wall, conveyor belt, floor) can serve as a reflector. When operating as a reflective barrier, objects between the ultrasonic sensor and the reflector are detected in any orientation (i.e., including, for example, objects at an angle that reflect sound away).

In the case of the ultrasonic through-beam barrier, two ultrasonic transducers are used, one of which acts as a transmitter and the other as a receiver. The evaluation electronics with the switching outputs are located in the receiver. For optimal use, the ultrasonic sensors are mounted exactly opposite each other on an axis. As soon as an object interrupts the sound path, the switching output of the ultrasonic sensor changes its state. For different distances between transmitter and receiver or different object sizes, the sensitivity of the receiver can usually be adjusted via teach-in or potentiometer.

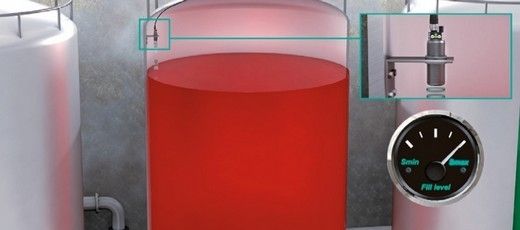

Level measurement in a tank using an ultrasonic sensor as a reflection sensor.

Which Application Areas Are Best Suited to Using Diffuse Mode Sensors, Retroreflective Sensors, and Thru-beam Sensors?

Ultrasonic diffuse mode sensors are especially suitable for level measurement tasks since fill levels in a tank or silo usually change relatively slowly. The switching frequency or the required response time is therefore significantly lower than for object detection in the thru-beam sensor operating mode.

Ultrasonic retroreflective sensors are ideal for objects that do not reliably offer a surface that reflects sound, such as inclined and sound-absorbing surfaces. This operating mode bypasses the issue of a dead band.

It doubles the detection range and enables objects to be reliably detected at significantly greater sensor distances. Since the sensors do not need to switch continuously between emitting and receiving mode, their response behavior is significantly quicker. This results in a much higher switching frequency. The process of counting passing bottles, for example, requires a very high switching frequency. Ultrasonic sensors that are operated as thru-beam sensors are a suitable solution for this.

Reliable detection of an oblique object on a conveyor belt using the ultrasonic sensor operated as a retroreflective sensor.

Can Objects Enter the Radius of the Sound Cone From Any Direction?

The objects being detected can enter the sound cone from any side. The expected switch points can be determined using the detection ranges and response curves specified in the datasheets. The response curve shown in the datasheet is based on room temperature and the diameter of the curve changes as the respective temperature changes. The resulting deviations in the responsiveness of the sensor may need to be considered if the object enters the sound cone radially.

Take a closer look at how ultrasonic sensors work in our animation:

More Information

- Ultrasonic Sensors

- Diffuse and Retroflective Mode Sensors

- Thru-Beam Sensors

Subscribe to our newsletter and receive regular news and interesting facts from the world of automation.