Boosting Productivity with the Help of Laser Barcode Scanners

Content of This Article

Boosting Productivity with Laser Barcode Scanners

Laser barcode scanners have been used in material handling applications for decades. It is an integral part of routing boxes down a conveyor line. The production of products such as liquid soaps, lotions, and shampoo will use barcode readers also. They are used in two places. First, to read the pallets of raw material bottles at the beginning of the production line, then secondly, at the end of the line after barcodes are applied to the bottles. The barcode readers have to read at very high read rates of over 200 bottles per minute.

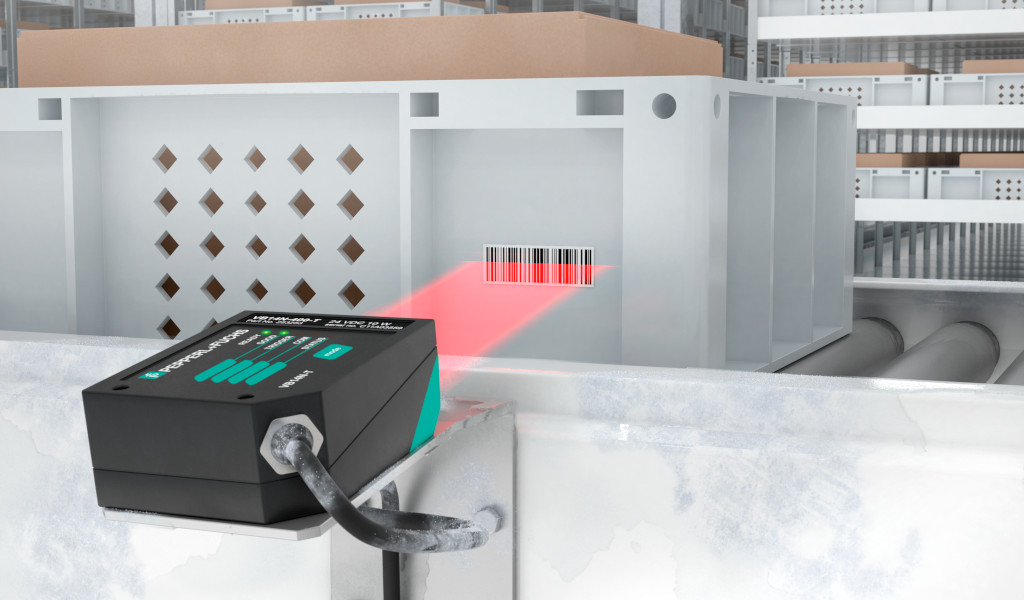

1. Line scanner

There are a number of different types of laser barcode readers. The first is just a normal line scanner. This would be a reader that has a single laser line used to read products. As long as the barcode is moving perpendicular to the laser line then this is the right choice.

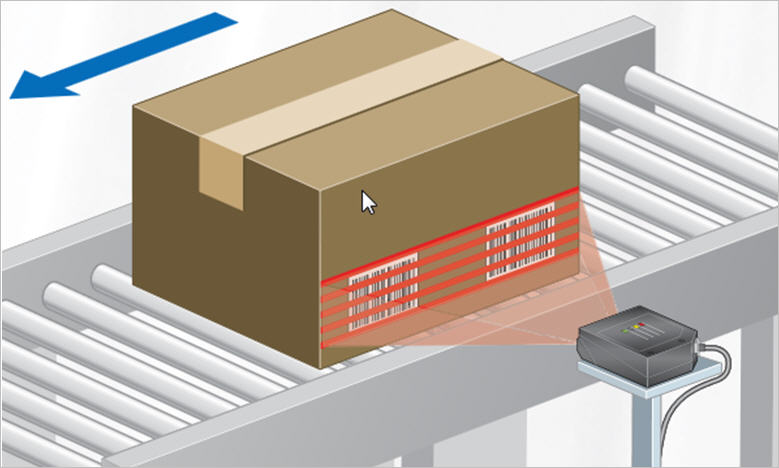

2. Raster scanner

Another type of laser barcode scanner is one that has multiple lines. This is called a raster scanner. It is used in applications where the barcode is moving parallel to the laser line. The problem with this setup is that if there is a defect in the barcode and that defect happens to be in the spot where the laser line is located then you have no chance to read the barcode. The multiple lines of a raster scanner give you the extra chances you need to read the barcode.

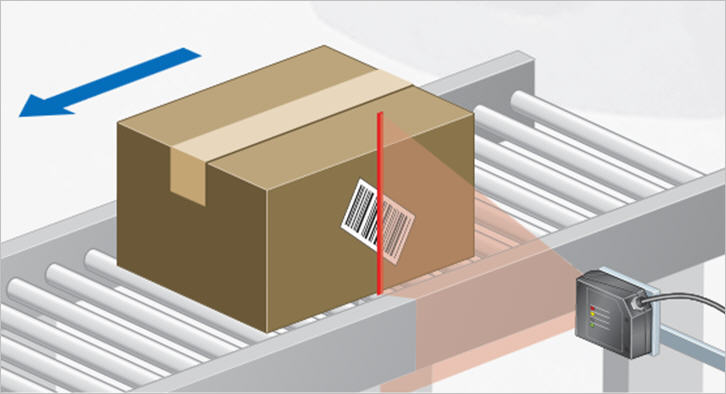

3. Laser scanner with oscillating mirror

If the barcode location on the box is unknown or variable then you may want to use a standard laser scanner with oscillating mirror. This will sweep the side of the box up and down and give you an output when the barcode reader is found. This box has to be moving slow enough so the barcode reader has a chance to read the moving barcode. The oscillating mirror sweep angle and speed can be adjusted based on the application.

4. Special barcode readers for tilted barcodes

Special barcode readers are required to read a barcode that is tilted. These barcodes have to have a known fixed length, and a reconstruction algorithm in the reader is used to stitch the barcode back together after it is read. You can see in this case that the laser scanner does not completely go through the barcode at one time.

Conclusion

Laser barcode scanners if used correctly are a highly reliable form of product identification. They are extremely fast and often are used in read-on-the-fly applications. Because laser scanners can run continuously and are triggered well before the barcode is in front of the reader, they can be very forgiving and fast. Unlike barcode imagers, where precise alignment is critical, laser scanners can look for a barcode that is located anywhere on the side of a box. The large depth of field allows a barcode to be on a small box 600 mm away or a large box that is only 200 mm away. It is true however that the more precisely the alignment and location are controlled, the more reliable the read will be.

More Information

Subscribe to our newsletter and receive regular news and interesting facts from the world of automation.