Mounting and Remotely Monitoring Dual Inductive Sensors on Manual Valves

Content of This Article

- The Optimal Mounting Solution—Even for Valves without Tapped Holes

- For Which Types of Valves Can the Clamping Solution Be Used?

- Which Mounting Accessories Are the Best Choice for Your Valve?

- How Are the Dual Inductive Sensors Mounted?

- Can I monitor the valve position remotely?

- How is the WILSEN.valve mounted?

- Products and Mounting Accessories

- More Information

Mounting and Remotely Monitoring Dual Inductive Sensors on Manual Valves

Many of the manual valves in chemical or petrochemical plants are not yet monitored using an automated process. Retrofitting with dual inductive sensors makes it possible to keep a constant overview on whether the valves are opened and closed correctly. Pepperl+Fuchs offers an extensive range of sensors for monitoring the opened/closed position of the valves that are suitable for a wide variety of operational conditions. The WILSEN.valve is a smart IoT sensor solution for remote monitoring of the valve position on manual control valves, which can be easily connected to the sensors. But what is the best way to install these components in your plant? Read this blog article to find out more about Pepperl+Fuchs mounting accessories.

The Optimal Mounting Solution—Even for Valves without Tapped Holes

When choosing the optimal mounting solution, the fact that many of the solutions available on the market require a tapped hole in the shaft end can present a real challenge. Since a number of valves do not meet this requirement, in some cases a hole will be drilled specifically for installing the dual sensor.

Plant operators no longer need to spend time and money on this process because Pepperl+Fuchs now offers a mounting solution that does not need a tapped hole—the valve can simply be clamped to the stub shaft. This means that valves without tapped holes can be automated quickly and easily.

For Which Types of Valves Can the Clamping Solution Be Used?

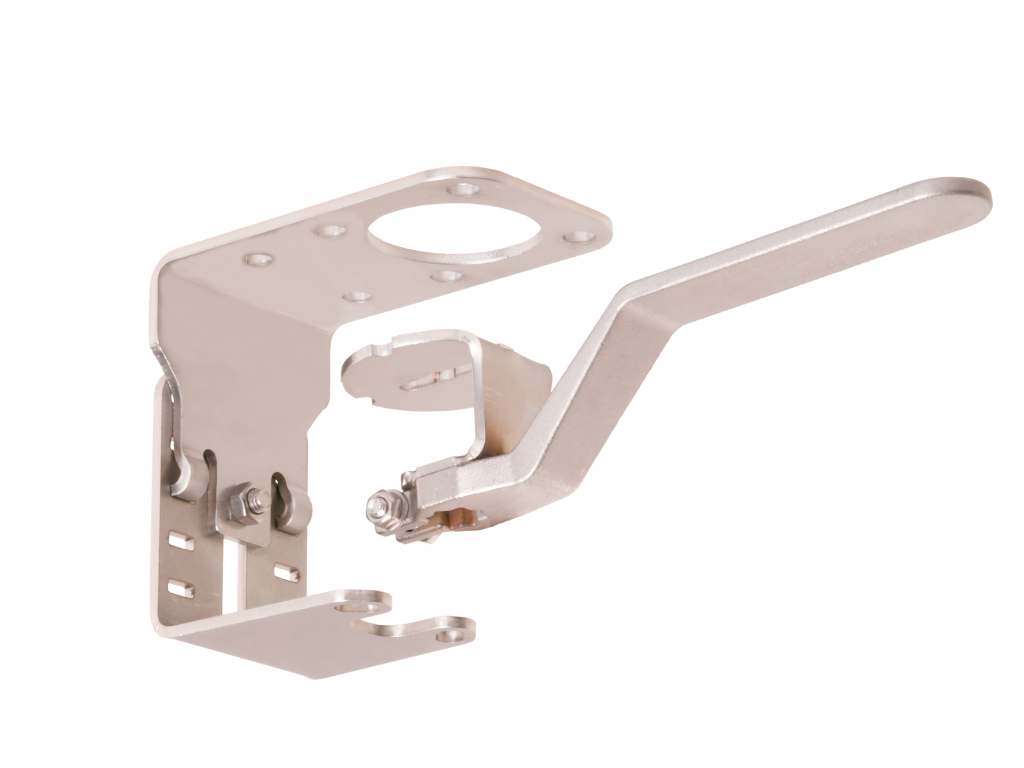

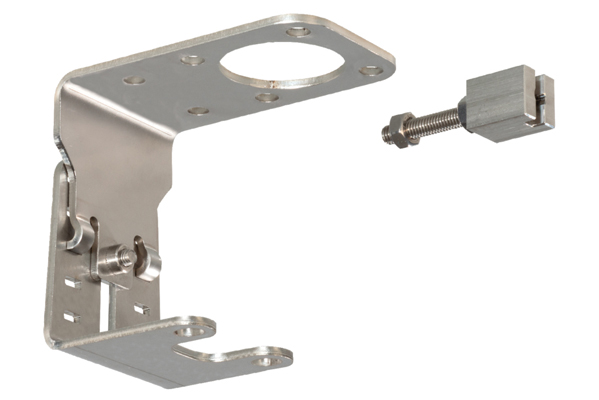

The Pepperl+Fuchs clamping solution consists of two parts that are purchased separately: A two-part mounting base and hand-operated lever, and an adapter plate on which the sensor and activator are mounted. The solution is suitable for mounting dual inductive sensors on almost any standard manual valve. The only consideration to be made is the shape of the drive shaft, as it must be square to ensure that the clamping solution can be installed without any issues. However, in some project conditions, it is possible to implement engineered solutions for non-square geometries.

Which Mounting Accessories Are the Best Choice for Your Valve?

Both the mounting base and the adapter plate used for mounting the sensor and activator are available in several versions. Find out below which versions are the best choice for your plant.

The Optimal Mounting Base

The size of the valve is the key factor in selecting a suitable mounting base. Mounting bases of the MHV-BT series are available for ISO5211 standard sizes F03, F04, F05, F07, and F10 manual operated valves. The associated hand-operated lever is simply attached to the drive shaft and ensures smooth rotation, allowing valves to be opened and closed quickly and easily.

MHV-BT mounting kit for valve shafts with square tappet: The adjustable two-part stainless steel mounting base including hand-operated lever is not screwed into the drive—it is clamped onto the outside of it.

MHV-BT mounting kit for valve shafts with internal thread: The height-adjustable mounting set made of stainless steel for manually operated valves according to EN ISO5211 with threaded hole allow for easy mounting.

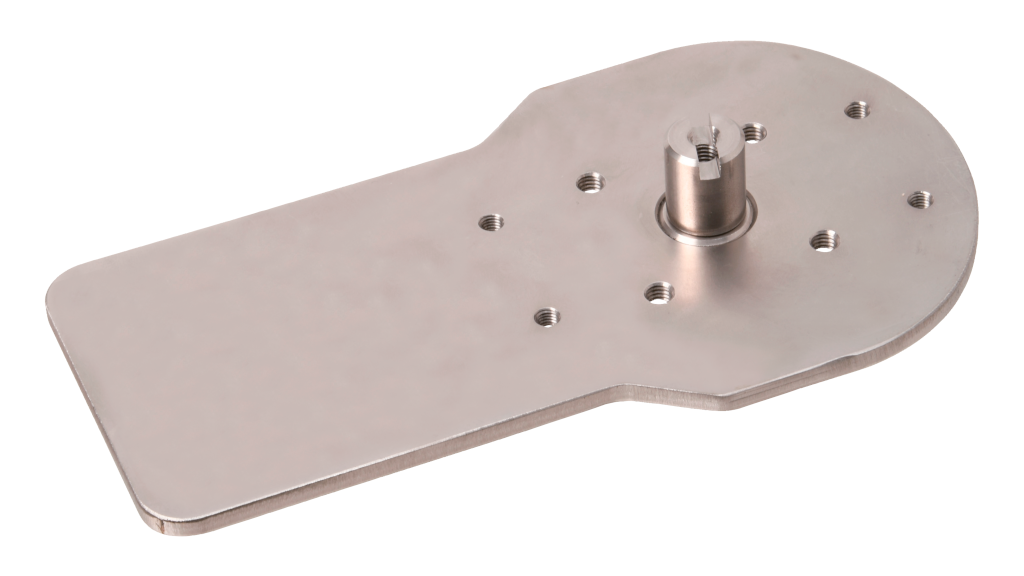

The Optimal Adapter Plate

The adapter plate is available in either a small or a large version: The best choice for your plant depends on the size of the valve, sensor, and activator. Both adapter plate versions have a ball bearing drive shaft that runs very smoothly and does not cause friction, even in aggressive ambient conditions. Since the adapter plates are made of stainless steel, they can also be used in outdoor areas with a high risk of corrosion.

The MHV-BT-F25/F31 small adapter plate is suitable for smaller dual inductive sensors: It can be fitted with sensors from the F25, F25K, and F31 series, which are often used as compact solutions on smaller manual valves. In addition to these dual sensors, the BT32, BT33, and BT65 standard activators are located on the adapter plate.

The small adapter plate MHV-BT-F25/F31

The small adapter plate offers enough space to mount the F31 dual sensor in combination with the BT65 activator, for example.

In contrast, the two larger Pepperl+Fuchs sensors can be mounted on the MHV-BT-F31K/F31K2 large adapter plate. These sensors are the F31K version with clamping space, and the F31K2 version, which is suitable for outdoor and offshore applications due to its extremely rugged housing. The large adapter plate is not only suitable for standard activators—it can also be used to mount activators with colored valve position indicators.

The large adapter plate MHV-BT-F31K/F31K2

The large mounting base is suitable for mounting the F31K2 dual sensor and an activator with a colored valve position indicator, for example.

How Are the Dual Inductive Sensors Mounted?

Using the mounting accessories from Pepperl+Fuchs, the dual sensors can be installed in your plant in just a few steps:

- First, attach the lower part of the mounting base to the valve and place the lever on the square shaft.

- Then attach the adapter plate to the top of the mounting base and screw the dual sensor and activator to the plate.

- Next, attach the top of the mounting base to the bottom of the mounting base.

- The height can be adjusted, making it easier to find the right position so that the switching shaft of the adapter plate and the guide plate on the lever interlock.

Can I monitor the valve position remotely?

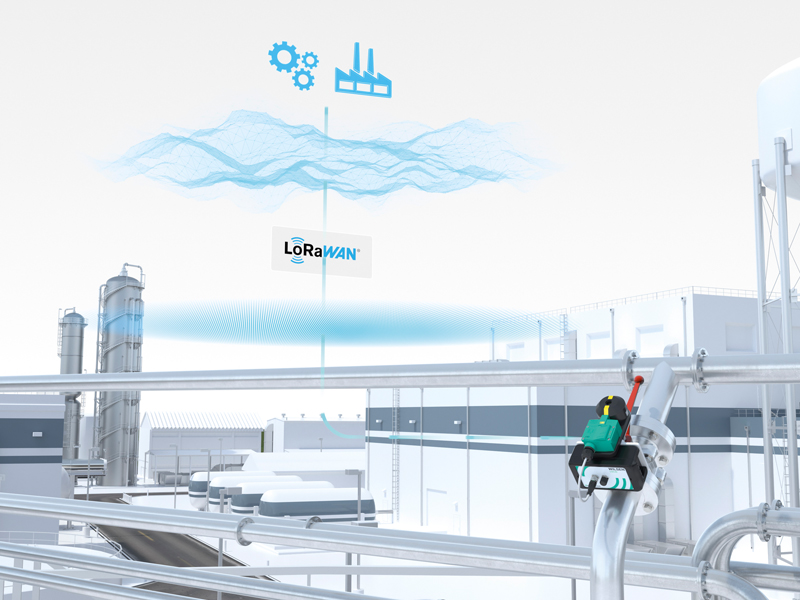

With the smart IoT sensor WILSEN.valve, Pepperl+Fuchs offers a radio-based solution for simultaneously transmitting the position of up to two 90° hand lever valves wirelessly, even in remote locations or in extensive plants. Two inductive sensors or one dual inductive sensor can be connected to a WILSEN.valve sensor. The valve position (open, closed or intermediate position), parameter and diagnostic data, as well as error states such as short circuits and lead breakage, are sent to the control room at a selectable transmission interval via the radio-based LoRaWAN network. This means that even manually operated valves can be easily and smartly integrated into the communication with the control system.

Note: The WILSEN.valve must not be installed in explosion-hazardous areas.

How is the WILSEN.valve mounted?

The WILSEN.valve can be mounted directly on the valve together with a dual inductive sensor and associated activator. The IoT sensor is connected to the sensors for valve position feedback. A ready-to-use mounting solution according to EN ISO 5211 is available as an accessory. It includes a mounting angle, adapter plates for dual inductive sensors, as well as complete mounting kits, and allows for quick and easy installation on all common manual valves and fittings.

The appropriate mounting bracket for the WILSEN.valve (MHV-WS-F406-F05-M5) can be screwed directly onto the corresponding adapter plate (MHV-BT-F-F25/F31 or MHV-BT-F31K/F31K2) for dual inductive sensors of the F25, F25K, F31, F31K, F31K2 series, and the adjustable mounting kits of the MHV-BT-F series for manually operated valves.

The WILSEN.valve mounting bracket can be flexibly and compactly mounted directly under the adapter plate of the dual inductive sensors.

With the right mounting accessories from Pepperl+Fuchs, nothing stands in the way of automated monitoring of your manual valves, including wireless data transmission. If you need help selecting the right solution, our experts will be happy to assist.

Products and Mounting Accessories

- Dual inductive sensors for valve position monitoring

- Activators for dual inductive sensors

- MHV-BT mounting kits for dual inductive sensors on manual valves

- Small adapter plate for F25/F31 dual inductive sensors

- Large adapter plate for F31K-/F31K2 dual inductive sensors

- WILSEN.valve IoT sensors for remote monitoring of the valve position

- Mounting bracket for WILSEN.valve

Subscribe to our newsletter and receive regular news and interesting facts from the world of automation.