The Important Function of RFID in the Mining Industry

Content of This Article

The Important Function of RFID in the Mining Industry

The mining industry is turning to modern technologies to improve efficiency, worker safety, and operational performance. One technological advancement is the use of RFID (radio frequency identification). In this blog article, you will learn how RFID systems from Pepperl+Fuchs are changing the way mining operations are managed and monitored, offering a range of benefits from increased productivity to optimized inventory control to improved safety measures, and more. Two practical application examples demonstrate which RFID systems are used in the challenging environmental conditions of the mining industry.

Role of RFID in Mining

RFID systems consist of tags, read/write devices, and an evaluation unit that work together seamlessly to track and identify objects in real time. The read/write devices create an energy field which activates the tags. The tags, equipped with microchips and antennas, emit radio signals that are picked up by RFID read/write devices. These devices then transmit the collected data to an evaluation unit which processes the information and forwards it to a controller so that the information can be retrieved quickly and accurately. In the mining industry, this technology is being used to streamline various processes and overcome the challenges associated with traditional tracking methods, such as manual data entry, barcode scanning, manual inspection and reporting, and limited real-time visibility.

From RFID read/write devices and tags to evaluation units: The extensive RFID portfolio from Pepperl+Fuchs covers all the requirements of the mining industry.

Improving Asset Management

One of the most important applications of RFID systems in the mining sector is asset management. In mining, there are a large number of machines, vehicles, and equipment whose location and use need to be monitored. The RFID tags attached to the equipment enable real-time tracking and data collection, providing continuous location data and ensuring that each piece of equipment is accounted for and used efficiently. This not only reduces the risk of theft, but also optimizes resource allocation, which in the context of RFID-tagged assets means the optimized use of equipment to ensure it is deployed effectively, ultimately resulting in cost savings for mining companies.

Optimizing Inventory Control

RFID systems are critical to improving inventory control in the mining industry. By tagging raw materials, finished products, and even spare parts, mining companies can maintain accurate records of stock levels. This real-time insight into inventory allows for better planning and reduces the likelihood of production delays or stoppages due to material shortages. In addition, RFID technology helps to minimize errors associated with manual data entry, which in turn contributes to a more streamlined and error-free inventory management process.

Ensuring Worker Protection

Worker protection is extremely important in any industrial environment, and the mining industry is no exception. RFID systems are being used to improve worker protection by identifying personnel within mining sites. By issuing RFID-enabled ID cards to workers, mining companies can monitor their accesses, ensuring that they adhere to designated safety zones and avoid hazardous areas. In the event of an emergency, RFID systems allow for quick and accurate head count, supporting rescue efforts and reducing potential risks.

Streamlining Logistics and Supply Chain

Efficient logistics and supply chain management are also essential components of successful mining operations. RFID systems play a key role in optimizing these processes by providing real-time visibility into the transport of materials and products. From the extraction site to the processing plants and distribution centers, RFID technology enables precise monitoring of shipments, reducing delays, and improving overall supply chain efficiency.

Meeting Regulatory Compliance

The mining industry is subject to strict regulations to ensure environmental sustainability and personnel protection. Pepperl+Fuchs RFID systems and solutions help ensure compliance by providing accurate data that can be easily audited and verified. From tracking the origin of raw materials to monitoring the disposal of waste—our RFID technology helps mining companies maintain comprehensive records to facilitate compliance with regulatory requirements.

Contributing to Sustainability

The mining industry is constantly evolving, and the integration of Pepperl+Fuchs RFID products and solutions is contributing to the progress. The advantages of improved asset management, optimized inventory control, increased worker safety, and streamlined logistics are advancing all mining operations and processes. By making processes more efficient and optimizing the use of resources, the implementation of RFID technology also puts the mining industry on the path to sustainability.

RFID Systems in Mining—Two Application Examples

The RFID systems used in mining must withstand particularly challenging conditions—from extreme ambient temperatures to iron ore and dust in the air. Pepperl+Fuchs offers highly robust and resistant RFID solutions that are ideally suited to these challenges.

Efficient Water Supply Management: F192 UHF RFID Read/Write Device

Sprinkler systems in mining are often operated with reservoir trucks that are supplied with water via a filling system. An RFID system offers the ideal solution for adjusting the amount of water to the capacity, ensuring the traceability of the vehicle at the same time: The robust F192 UHF RFID read/write device is used for this purpose. Due to IP67 degree of protection and an extended temperature range, maximum process reliability is guaranteed even under challenging environmental conditions. The RFID read/write device identifies the vehicle via the cost-effective IUC87-F257-T17-M-FR* UHF tag, which can be mounted directly on the vehicle’s tank. The measured values are then forwarded via the IDENTControl evaluation unit so that the water flow can be optimally regulated. For reliable asset tracking, the UHF transponder can store additional information about the vehicle, such as its real-time status or location.

Reliable Positioning of Yard Machines: F190 UHF RFID Read/Write Device

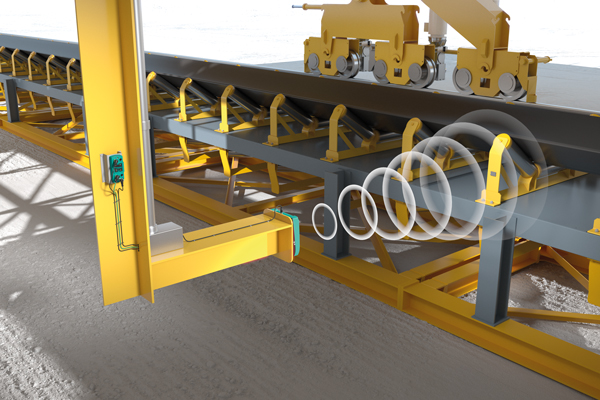

With bucket wheel reclaimers, the position of the machine must be monitored across the entire storage yard to ensure reliable stacking of materials. For this purpose, UHF tags of the type IUC87-F257-T17-M-FR* are attached to predefined positions along the entire length of the travel path. An F190 series UHF RFID read/write device is attached to the yard machine and reads the tags at adjustable intervals of up to two meters. The RFID read/write device is ideal for this task because it can withstand the harsh environmental conditions in mining and even direct contact with ore. Each time a new tag is read, the system automatically sends a signal to the PLC and compares it with the additional position values provided by an ENA58IL series absolute encoder. This ensures that the position of the machine is reliably measured at all times.

Subscribe to our newsletter and receive regular news and interesting facts from the world of automation.