How to Easily Implement Intrinsic Safety with Ethernet-APL

Content of This Article

How to Easily Implement Intrinsic Safety with Ethernet-APL

Ethernet-APL is a physical layer that is defined for the special environmental conditions in the field of process plants and enables continuous, digital data transmission to the process control level or cloud. Ethernet communication follows the specification of 10BASE-T1L standardized in IEEE 802.3cg. Explosion protection is a basic requirement for this area of application. In the definition of Ethernet-APL, intrinsic safety is an integral component which enables all market participants to use this type of protection worldwide and to operate devices of any manufacturer in a network. Learn more about the ease of realizing an intrinsically safe Ethernet-APL network in this blog article.

2-WISE—an Intrinsically Safe 2-Wire Ethernet

Intrinsic safety is a type of protection defined for every potentially explosive area—whether they are zones or classes/divisions—and has been established worldwide for decades for the safety of people, the environment, and plants. The handling is simple and familiar. Due to the intrinsic safety type of protection, it is possible to work safely on electrical circuits without requiring a hot work permit. The blue signal color on the cables and terminals of the field devices clearly indicates the intrinsic safety degree of protection.

From the very beginning, an intrinsically safe 2-wire Ethernet was the vision of Pepperl+Fuchs specialists. Together with several well-known automation manufacturers for the process industry, they succeeded in making Ethernet-APL accessible to a broad market worldwide. One of several essential elements defining Ethernet-APL is the IEC 60079-47:2021 (TS) 2-WISE standard. The abbreviation 2-WISE stands for “2-Wire Intrinsically Safe Ethernet” and describes an intrinsically safe 2-wire Ethernet.

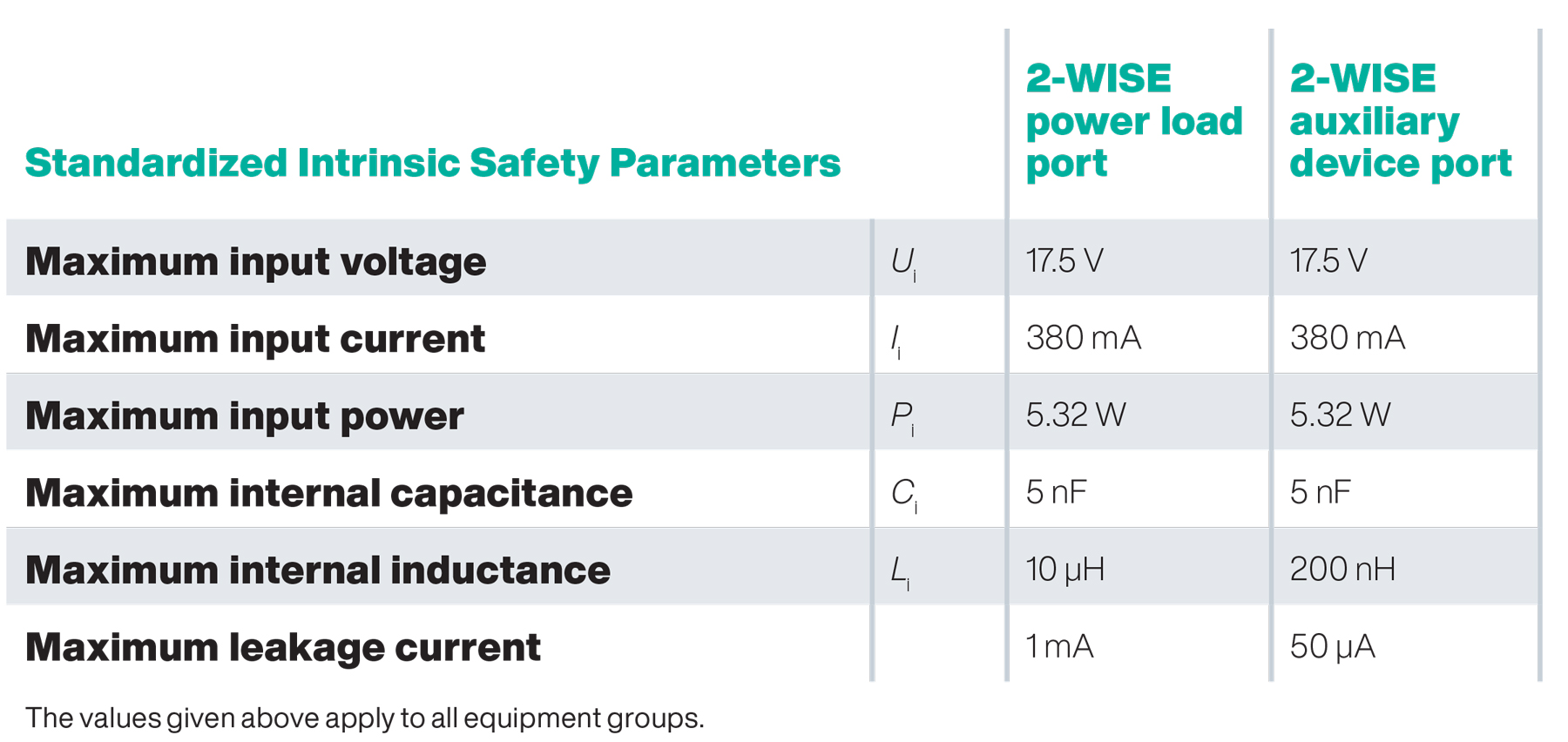

2-WISE defines two classes (see Table 1 below) that cover all practical use cases. These protection classes define limit values for all physical values, so that they always result in a safe combination if selected correctly. Compliance is verified and certified for devices and infrastructure components during certification. The 2-WISE concept for Ethernet-APL therefore greatly simplifies the proof of intrinsic safety.

Table 1: Intrinsic safety limits observed by manufacturers. (www.ethernet-apl.org)

Implement Intrinsic Safety with Ethernet-APL

The implementation of intrinsic safety with Ethernet-APL essentially involves three steps:

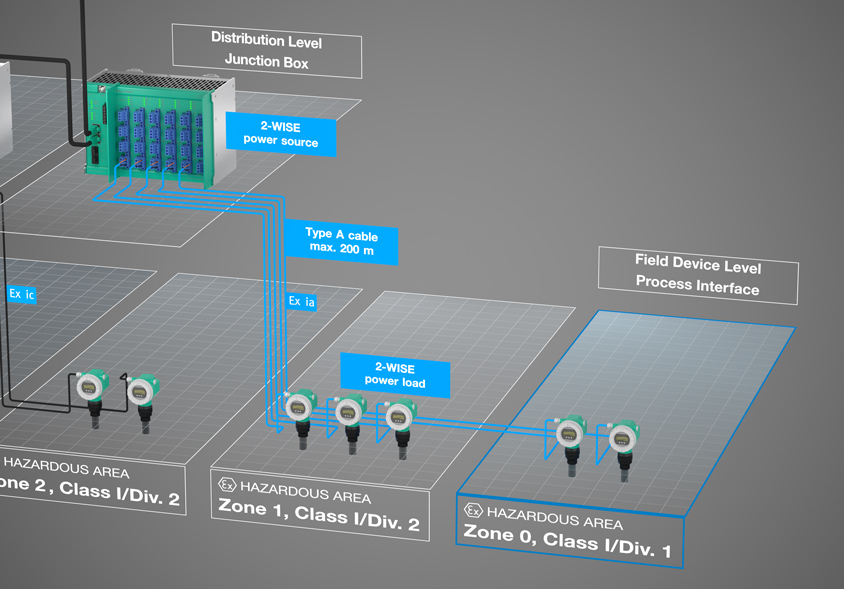

- Select the parameter set to match the hazardous area. Then you select switches, infrastructure, and devices. Only point-to-point connections exist—exactly one energy source and one energy sink. This is the simplest network.

- Select a suitable cable. A cable length of up to 200 meters is possible. The cable connecting the switch and the field device must meet the requirements for resistance, capacitance, and inductance. The fieldbus type ‘A’ cable already has the necessary properties defined with 2-WISE.

- Document the technical parameters, components, and devices used in a table, which could be created automatically by the engineering system, for example. Standardized parameters for source, sink, and cable, as well as the cable length result in intrinsic safety.

Watch the video and learn how to realize intrinsic safety with Ethernet-APL:

Simple Verification of the Intrinsic Safety of Ethernet-APL with 2-WISE

In practical applications, the implementation of the intrinsic safety of Ethernet-APL with 2-WISE is unbeatably simple. Without calculations and only with the already necessary planning steps for Ethernet-APL-compatible devices and infrastructure, the planner already provides proof of intrinsic safety. These only need to be documented. The planning guideline for Ethernet-APL (Engineering Guideline) contains templates for the legally required documentation and explains all necessary rules compressed on a few pages. Anyone familiar with fieldbus systems will discover many similarities to the FISCO (Fieldbus Intrinsically Safe Concept) model. In fact, 2-WISE was developed from it, but allows for higher performance and therefore greater distances between the switch and the field device.

The fieldbus cable type ‘A’ already has the necessary properties defined with 2-WISE and allows cable lengths up to 200 meters.

With the intrinsic safety certificate according to 2-WISE, working on circuits without a hot work permit is permitted and thereby ensures a very high level of protection for people, the environment, and the system. The relevant specifications according to IEC 60079 14 and the national or regional regulations of the authorities apply to the installation. The ATEX, IECEx, and NEC505 approvals for Zones 0, 1 and 2 and the NEC500 approvals for Divisions 1 and 2 are available. Users only need to select and connect the Ethernet-APL-capable devices according to the hazardous area, and document the installation and changes and extensions to the network. This proves compliance with the required limit values according to 2-WISE. Ethernet in the field of process plants with potentially explosive areas can therefore be implemented by every user.

Subscribe to our newsletter and receive regular news and interesting facts from the world of automation.