What Are the Differences between the K-System and the H-System?

Content of This Article

What Are the Differences between the K-System and the H-System?

Pepperl+Fuchs offers two extensive product families for safely transmitting signals between the field and control levels: the K-System and the H-System. These product families include a wide range of interface modules for converting signals and isolating intrinsically safe and non-intrinsically safe circuits. The following article explains the differences between and benefits of these two systems, and explains for whom each system is most suitable.

What are the K-System and the H-System?

The K-System and the H-System contain intrinsically safe barriers that are used to protect intrinsically safe circuits in hazardous areas. In addition, the K-System includes signal conditioners that protect the signal transmission between field devices in the safe area and protect the control through galvanic isolation.

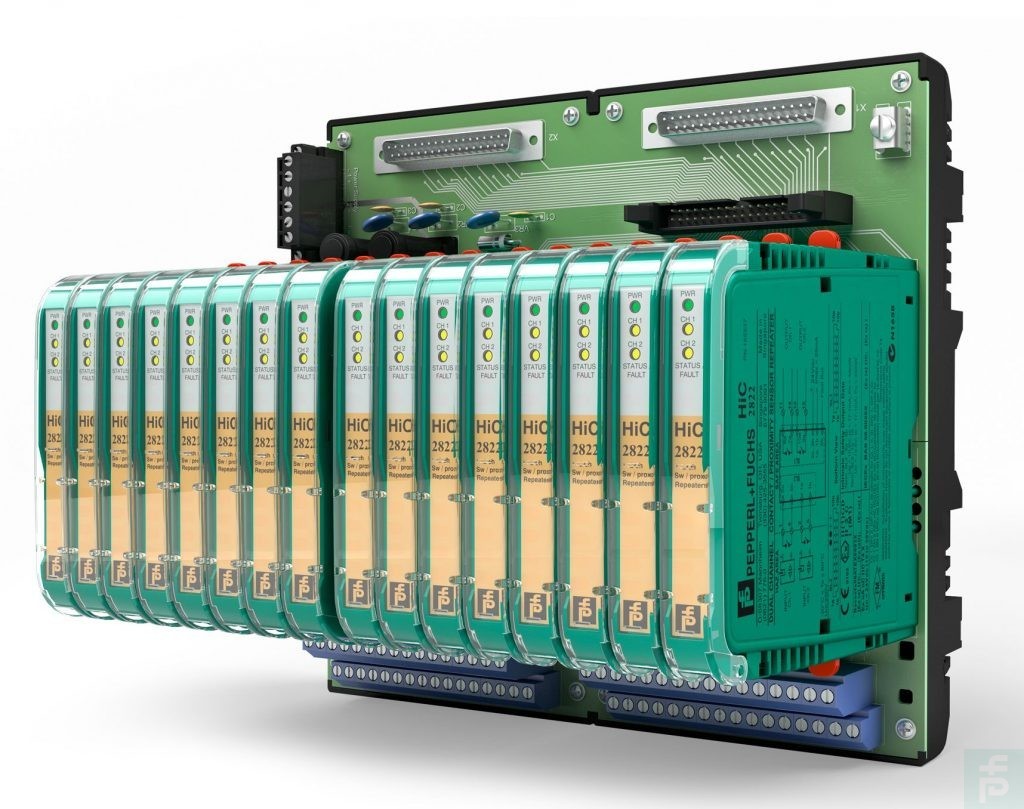

H-System termination boards enable direct connection to DCS, PLC, or ESD with standard system cables

Mounting and Power Supply

The key difference between the two systems is how the modules are mounted and supplied with power:

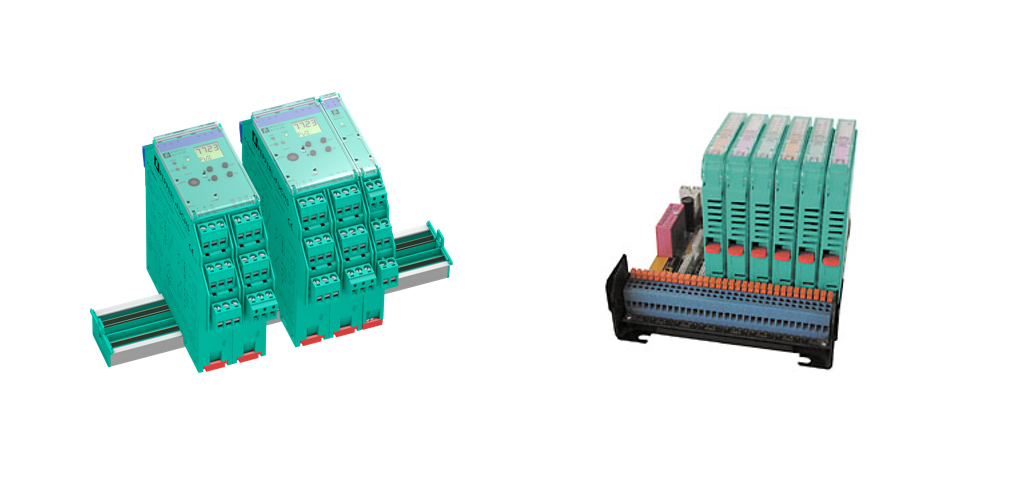

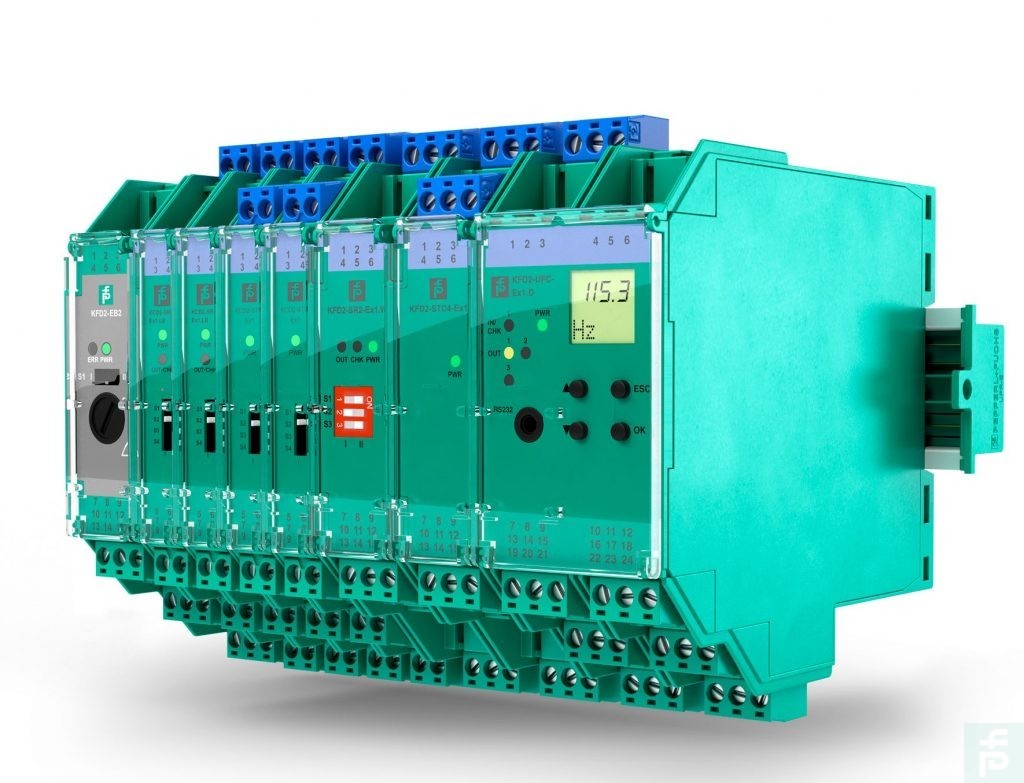

K-System devices are snapped onto a DIN mounting rail and are powered via terminals or via a Power Rail that transmits a collective error message at the same time. The Power Rail consists of a DIN mounting rail and a plastic insert with integrated power rails through which a module can supply power and receive collective error messages.

By contrast, H-System modules are installed on a termination board, which is then mounted on a DIN mounting rail. In this case, power is supplied via a terminal (with bus) with the termination board.

K-System isolated barriers transmit signals to and from hazardous areas

Wiring of Signal Lines

With the K-System, removable screw terminals or spring terminals can be used to wire the signal lines.

With the H-System, there is permanent wiring via a termination board (screw terminals on the field side and D-sub connectors on the control side). Specific system plugs and system cables are available for many control systems.

Which System Is Suitable for Whom?

Selecting the right system requires consideration not only of the wiring effort and parameterization options, but also of the application area.

Application Areas of the K-System

The K-System has a large number of modules for a multitude of signal types, and can be used in both hazardous and non-hazardous areas. It does not matter whether a simple switch amplifier or a high-performance component is being installed. The isolators in the K-System offer individual wiring on the control side, removable contacts on the field and control side, and operating elements on the front of the device. The modules are available in a 12.5 mm wide KC version and in a 20 or 40 mm wide KF version.

Advantages of the K-System

| Simple and Flexible Mounting and Supply |

|

| Simple Maintenance |

|

High Availability |

|

Application Areas of the H-System

The H-System offers a termination-board-based interface solution for large plants and systems directly connected to DCS (process control system)/ESD (emergency shutdown) systems. The termination boards connect the control system via system plugs that ensure quick, error-free wiring. The isolated barriers are available as 12.5 mm wide HiC modules for compact single-loop integrity or as 18 mm wide multichannel HiD modules for maximum packing density. To ensure maximum safety, the termination boards and associated components used are sufficiently tested for operating large plants, and they are optimally adapted to the respective process control system.

Advantages of the H-System

| Integration in the Control System |

|

| Simple and Flexible Mounting |

|

Summary

The key difference between the K-System and the H-System are the wiring effort and the application area. The K-System is suitable for a mixture of applications in both hazardous and non-hazardous areas due to its flexible mounting on a Power Rail. The isolators of the K-System offer individual wiring on the control side, removable contacts on the field side, and control elements on the front of the device. The H-System can be used in hazardous areas of large plants and systems directly connected to DCS (process control system)/ESD (emergency shutdown) systems. The components of the H-System can be mounted on termination boards without tools.

Subscribe to our newsletter and receive regular news and interesting facts from the world of automation.