Frequently Asked Questions (FAQ) on RIFD (Part 3): Frequencies

Content of This Article

Frequently Asked Questions (FAQ) on RIFD (Part 3): Frequencies

1. Which Frequencies Does RFID Use?

To enable noncontact data exchange via an RFID system, radio waves are used for communication. Depending on the application requirements, RFID systems utilize different frequency ranges. As a general principle, most RFID systems use the so-called ISM bands (Industrial, Scientific, and Medical Band) in order to avoid cross-talk of radio systems and ensure reliable data information exchange. Commonly, passive RFID systems use either low frequency (LF), high frequency (HF), or ultra-high frequency (UHF).

2. What Defines the Different Frequency Ranges of RFID?

Low-frequency RFID systems work at 125 to 134 kHz. They are characterized by a limited reading range (around 10 cm) but offer a reliable and quick enough solution for many common RFID applications. Because they handle moisture and metal environments quite well and are available in many different construction forms, they can be applied in harsh industrial environments as well as for access control, warehouse management, or livestock tracking.

High-frequency RFID systems work at 13.56 MHz and are characterized by a medium to high transfer rate. They are negatively affected by metal environments but rather insensitive to moisture and water. As a special feature, mobile devices like smartphones or tablets with NFC interfaces can be used as cost-efficient reading devices. You can find HF RFID in ticketing, payment, and data transfer applications.

Ultra-high-frequency RFID systems work at 865 to 928 MHz. They are characterized by a very high reading range (up to 12 m) and fast transfer speed. As UHF was originally a frequency range prone to disturbance by metal or moisture, manufacturers had to show their skilled craftsmanship in the design of UHF tags and readers that can handle these challenges. This has successfully happened and UHF has constantly evolved. In addition to the outstanding reading and speed properties of UHF systems, tags are also quite cost-effective—another big reason why UHF really took off.

3. Do All Countries Use the Same RFID Frequency Ranges?

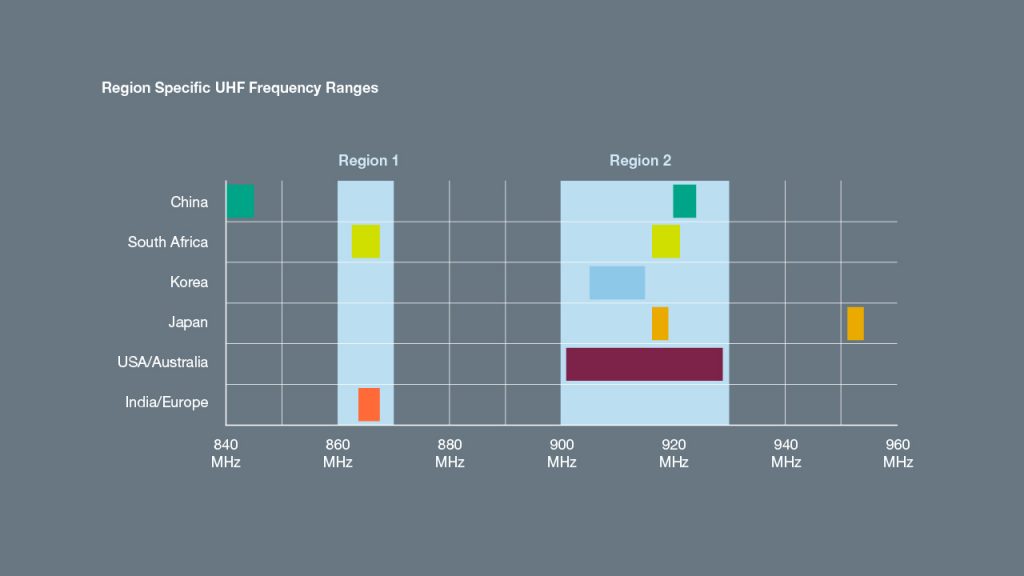

As explained in question 2, there are three different widely-spread frequency ranges used all over the world: LF, HF, and UHF. The low-frequency and high-frequency RF bands are mostly standardized and used equally from country to country. When it comes to the rapidly growing UHF market, things get more interesting. As you can see, the UHF frequency bandwidth varies from 865 to 928 MHz. This is due to the fact that UHF is the newest of all the standards and has only been around since the 1990s—so different areas still use different frequency ranges for UHF communication: the European Union utilizes 865 to 868 MHz, while North America sends at 902 to 928 MHz, and China has chosen 920.5 to 924.5 MHz. It may take some years until all governments and bodies finally agree on a single UHF RFID band. Until then, manufacturers provide devices in different frequency ranges for different areas. For instance, Pepperl+Fuchs offers the RFID UHF read/write heads F190 and F192 with identical design and functionality, but different transmission licenses for all relevant frequency ranges.

Overview of the frequency ranges used for UHF RFID worldwide

4. Which Factors Affect the Reading Range and Performance of an RFID System?

Besides the effects of nearby liquids (absorbing radio waves) or metal (reflecting and shielding), there are several other factors that weigh in when it comes to the performance of an RFID system. For instance, when an RFID tag is small, the reading range correspondingly remains low as well. The speed at which tags pass the reading device can also affect your results. Moreover, the positioning of tag and reader antenna towards one another must be taken into account to reach maximum reading range. RFID readers located nearby can affect the reading performance of devices as well.

As we already learned, water negatively affects the ability to reliably read tags. So when you want to use RFID outdoors, plan for rain and snow. Another extremely important criteria is of course the quality of the RFID equipment that you use. Not only does the RFID reader, tag, and control unit have to be state-of-the-art, but also the overall quality of your whole system installation has to be on par to achieve the best results and boost your identification process.

5. How Do I Know Which Frequency I Should Choose for My RFID System?

The desired reading range is an important factor which subsequently determines the frequency of the system you should choose. Think of an automotive assembly line: various tags are used on a car to identify different parts of the vehicle. Physically, it is not possible to reach all of these tags with the limited reading range of an LF RFID system. Also, when you want to transfer a larger amount of identifier data, UHF is the right choice with its very high transmission speed. Imagine a box stuffed with electronic parts on a roller conveyor, each part equipped with a tag that carries a wealth of product information: Once the box enters the reading range of the UHF read head, every bit of information on all of these products in the box is read at once in a “multitag reading.” These are some of the typical advantages which qualify UHF as a great solution for almost any industrial application that revolves around item tagging.

Alternatively, a low-frequency system is a good fit when it comes to detecting goods with high water content, such as fruits or vegetables. LF RFID systems also have proven to be very successful for animal identification where they are the standard solution. HF systems have made their way into our everyday life with their support of near-field communication devices and can be found in library books or personal ID cards.

More Expertise on RFID!

Visit our “RFID Hub”! On this special website, we have collected further FAQs, application examples and videos for you on the topic of RFID in automation. If you have any questions, our experts look forward to your inquiry at any time.

Subscribe to our newsletter and receive regular news and interesting facts from the world of automation.